A method for treating transition type and limonite type laterite nickel ore by using industrial pickling waste acid

A laterite nickel ore and industrial pickling technology, which is applied in the field of resource recycling and mineral processing, can solve the problems of low final product grade, high cost and energy consumption, and difficult product separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

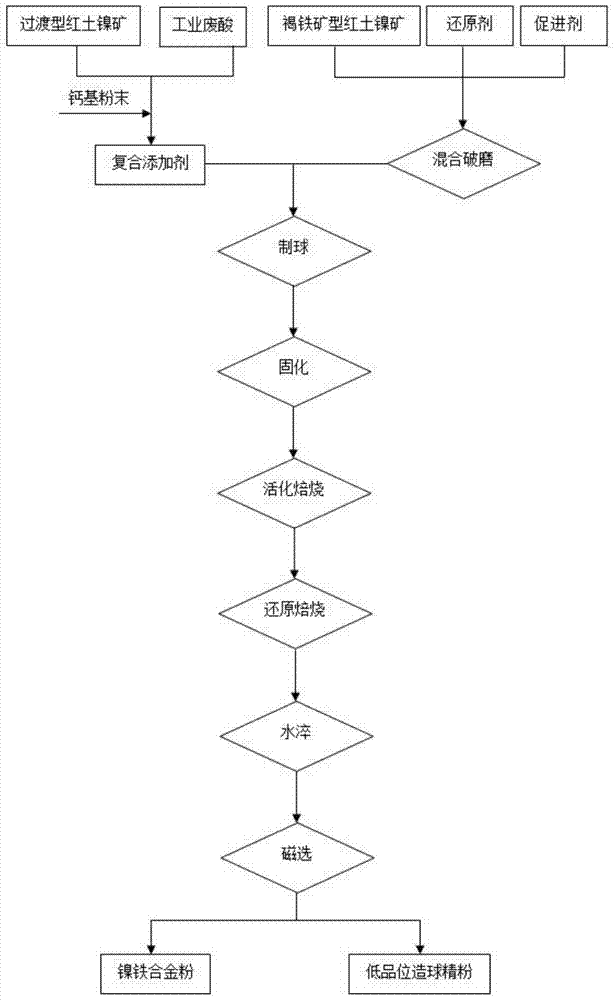

Method used

Image

Examples

Embodiment 1

[0077] (1) Preparation of composite additives:

[0078] Take 100mL of pickling waste liquid, add 20g of transitional laterite nickel ore, stir and react at a stirring rate of 120r / min for 20min, add 20g of calcium oxide during this period to adjust the pH of the solution to be stable between 6 and 7, and obtain a composite additive after the reaction is completed;

[0079] (2) Mix the dried limonite-type laterite-nickel ore, coke and sodium silicate and then grind them until the particles with a size of ≤100 mesh account for 85wt of the total amount of limonite-type laterite-nickel ore, coke and sodium silicate %; Wherein, the addition amount of coke is 10wt% of laterite nickel ore, and the addition amount of sodium silicate is 5wt% of laterite nickel ore. Then granulate on a disc granulator to obtain laterite nickel ore green pellets with a diameter of 8-12 mm. The amount of composite additives added in the granulation process is the total amount of limonite type laterite nic...

Embodiment 2

[0084] (1) Preparation of composite additives:

[0085] Take 100mL of pickling waste liquid, add 20g of transitional laterite nickel ore, stir and react at a stirring rate of 120r / min for 20min, add 20g of calcium hydroxide during this period to adjust the pH of the solution to be stable between 6 and 7, and obtain a composite additive after the reaction is completed;

[0086] (2) Mix the dried limonite-type laterite-nickel ore, white coal and sodium carbonate and then grind them until the particles of ≤100 mesh account for 85wt of the total amount of limonite-type laterite-nickel ore, white coal and sodium carbonate % or so; wherein, the addition of white coal is 8wt% of the laterite nickel ore, and the addition of sodium carbonate is 4wt% of the laterite nickel ore. Then granulate on a disc granulator to obtain laterite nickel ore green pellets with a diameter of 8-12 mm. The amount of compound additives added during the granulation process is the total amount of limonite ty...

Embodiment 3

[0091] (1) Preparation of composite additives:

[0092] Take 100mL of pickling waste liquid, add 20g of transitional laterite nickel ore, stir and react at a stirring rate of 120r / min for 20min, add 20g of calcium hydroxide during this period to adjust the pH of the solution to be stable between 6 and 7, and obtain a composite additive after the reaction is completed;

[0093] (2) Mix the dried limonite-type laterite-nickel ore, lignite and sodium hydroxide and then grind them until the particles with a size of ≤100 mesh account for 85wt of the total amount of limonite-type laterite-nickel ore, lignite and sodium hydroxide %; Wherein, the addition amount of lignite is 7wt% of laterite nickel ore, and the addition amount of sodium hydroxide is 3wt% of laterite nickel ore. Then granulate on a disc granulator to obtain laterite nickel ore green pellets with a diameter of 8 to 12mm. 20wt% composite additive; the obtained lateritic nickel ore green pellets were naturally cooled fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com