A kind of dsoi strain gauge and manufacturing method thereof

A manufacturing method and technology of strain gauges, applied in the direction of electric/magnetic solid deformation measurement, electromagnetic measurement devices, etc., can solve the problems of large output temperature drift, large offset voltage of full-bridge circuit, and reduced yield, so as to improve measurement accuracy , Reduce the offset voltage, reduce the effect of electric leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

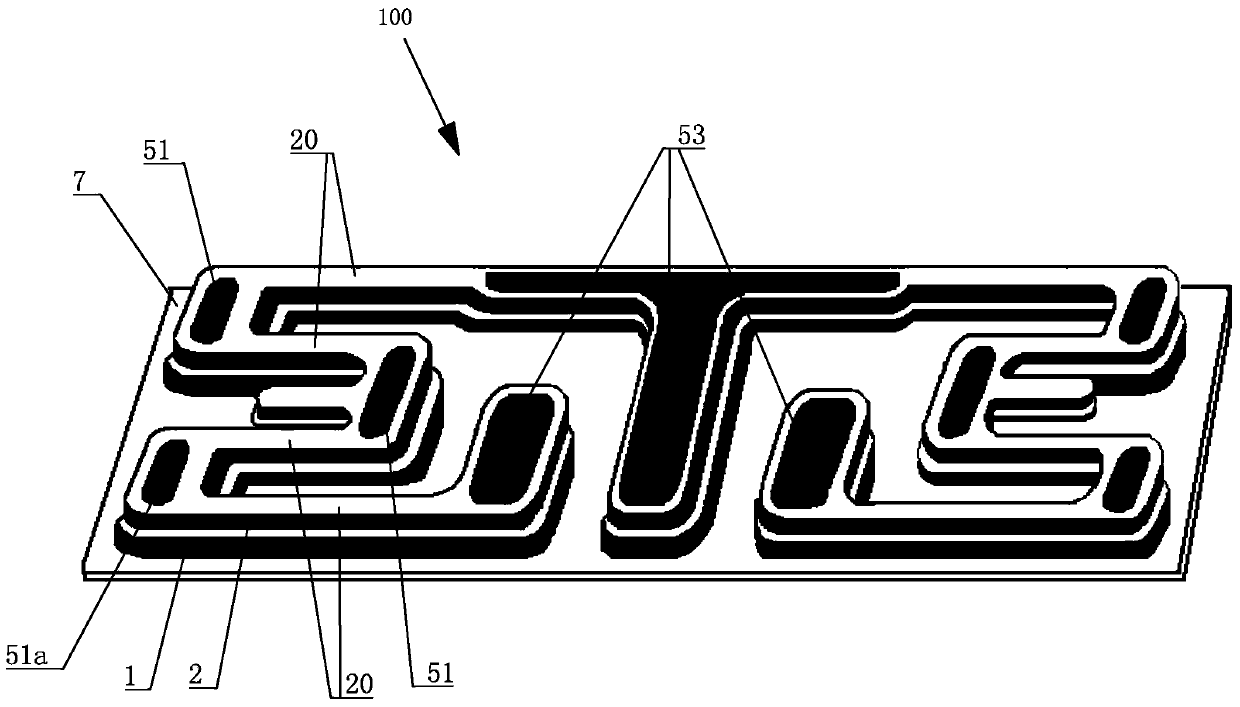

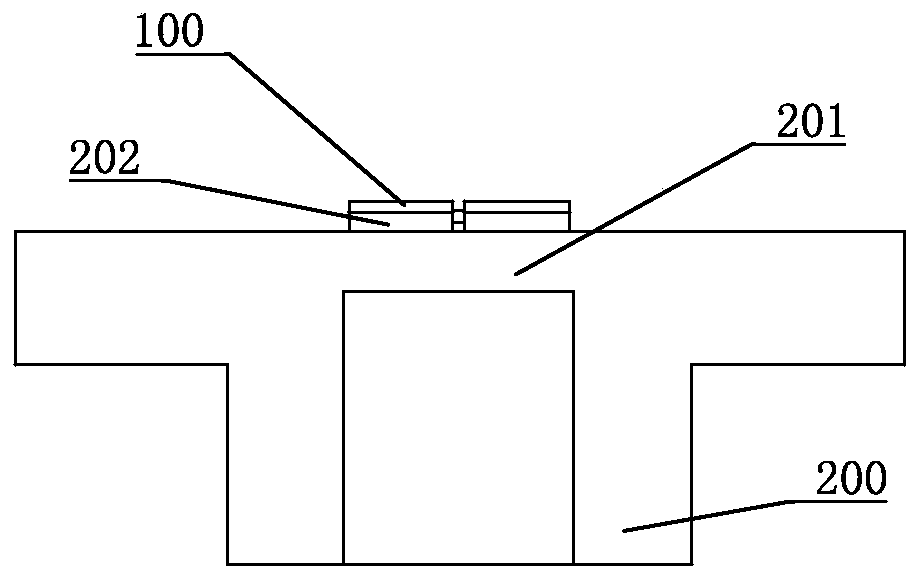

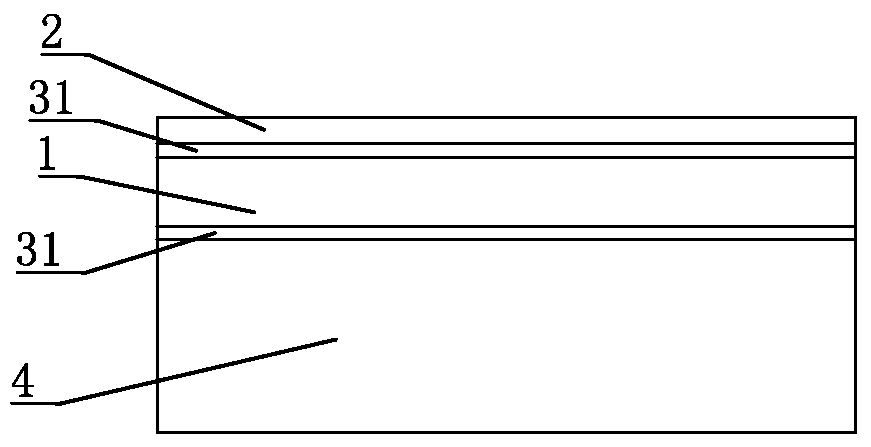

[0047] refer to Figure 1 to Figure 16, a DSOI (double silicon oxide insulation) strain gauge of the present invention, including a strain gauge 100, the entire structure of the strain gauge 100 is divided into two layers, including a device film layer 2 with an upper surface of 2-5µm and a lower surface of 12-15µm The substrate layer 1 is used to support the upper surface layer. The device thin film layer 2 can be made of single crystal silicon or polycrystalline silicon material. The substrate layer 1 can be made of single crystal silicon or polycrystalline silicon material. The thick insulating film layer 31 is isolated, instead of the P-N junction isolation, to ensure the absolute isolation of electrical properties between the two, and to improve the working temperature range of the sensor, which can meet the requirements of the sensor in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com