Preparation method of NiMoO4/MoS2/NiS nanocomposite

A nano-composite material, 6mo7o24 technology, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problem of unsatisfactory cycle performance, and achieve the effects of improving poor cycle stability, inhibiting agglomeration, and scientific and reasonable methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

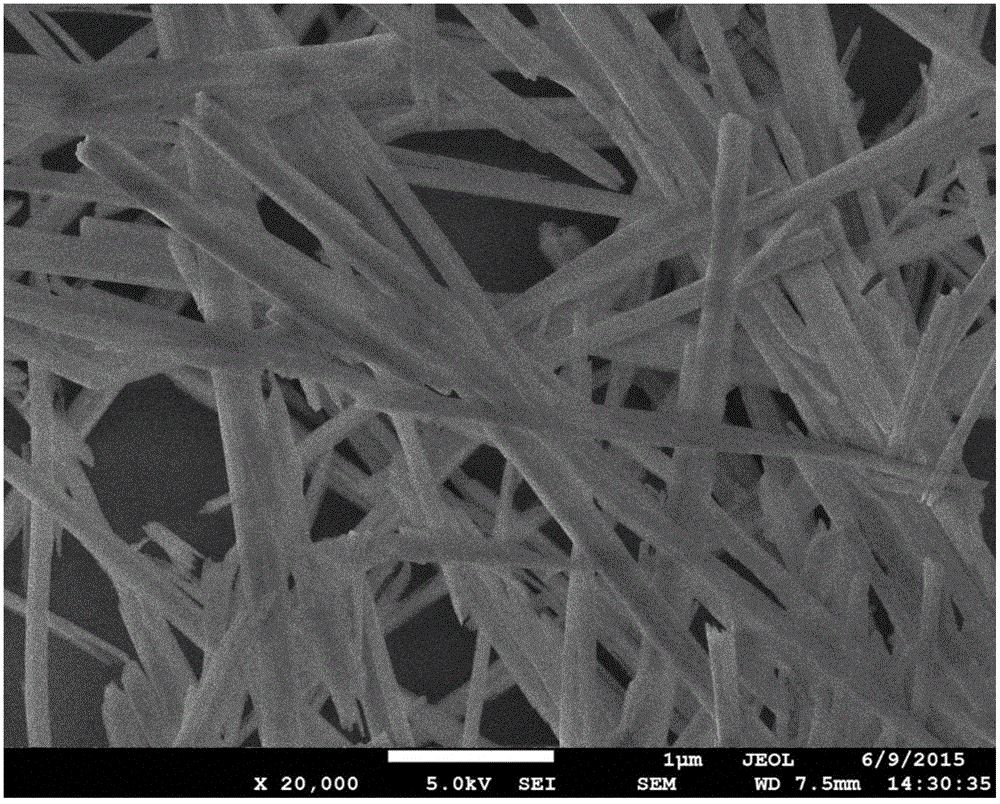

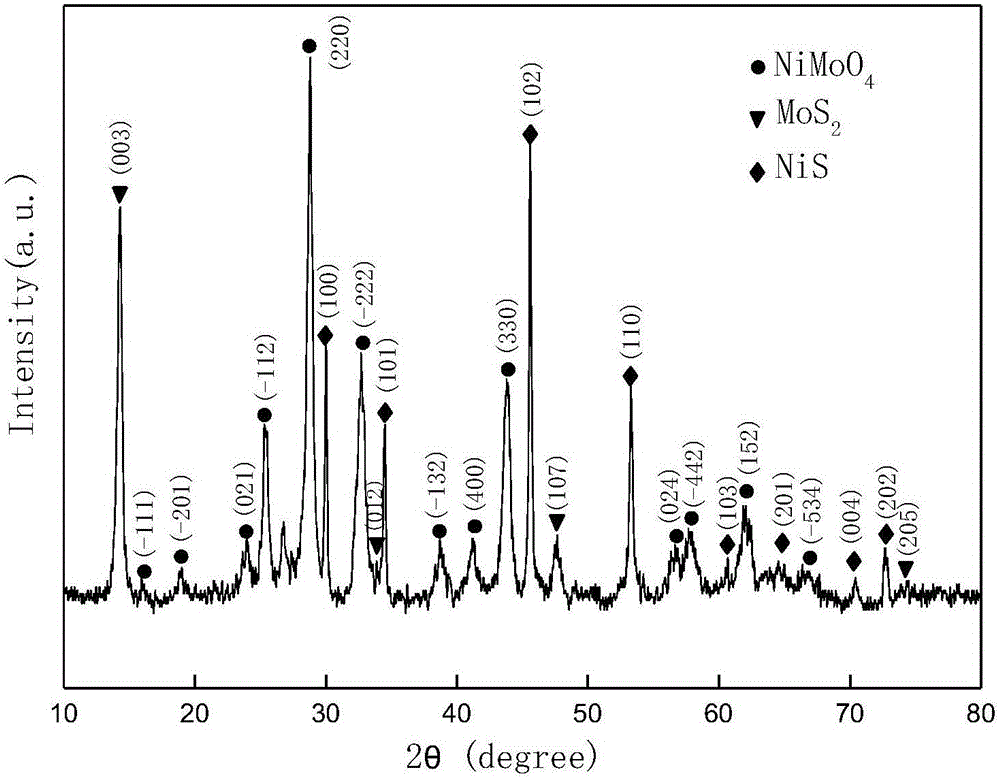

[0023] A kind of NiMoO of embodiment 1 4 / MoS 2 / NiS nanocomposite preparation method, the preparation steps are:

[0024] (1) Weighing (NH 4 ) 6 Mo 7 o 24 ?4H 2 O0.21mmol, Ni(CH 3 COO) 2 ?4H 2 O0.74mmol and H 2 NCSNH 2 Add 1.47mmol into 70mL ultrapure water, stir for 20min;

[0025] (2) Transfer the mixed solution to a reaction kettle with a volume of 100mL, and react at 160°C for 24h;

[0026] (3) After the reaction, cool to room temperature and centrifuge at a speed of 3000r / min for 4min. The centrifuged product is washed three times with ultrapure water, then washed three times with absolute ethanol, and dried in a vacuum oven at 60°C 12h;

[0027] (4) Place the dried product in a vacuum gas-filled tube furnace under N 2 Under the protection of , calcined at 400°C for 2h, and the heating rate was 4°C / min, to obtain NiMoO 4 / MoS 2 / NiS nanocomposites.

Embodiment 2

[0028] A kind of NiMoO of embodiment 2 4 / MoS 2 / NiS nanocomposite preparation method, the preparation steps are:

[0029] (1) Weighing (NH 4 ) 6 Mo 7 o 24 ?4H 2 O0.24mmol, Ni(CH 3 COO) 2 ?4H 2 O1.34mmol, H 2 NCSNH 2 Add 3.36mmol and NaCl1.68mmol into 70mL ultrapure water, stir for 20min;

[0030] (2) Transfer the mixed solution to a reaction kettle with a volume of 100mL, and react at 170°C for 24h;

[0031] (3) After the reaction, cool to room temperature and centrifuge at a speed of 3000r / min for 4min. The centrifuged product is washed three times with ultrapure water, then washed three times with absolute ethanol, and dried in a vacuum oven at 60°C 12h;

[0032] (4) Place the dried product in a vacuum gas-filled tube furnace under N 2 Under the protection of , it was calcined at 400°C for 2h, and the heating rate was 4°C / min.

Embodiment 3

[0033] A kind of NiMoO of embodiment 3 4 / MoS 2 / NiS nanocomposite preparation method, the preparation steps are:

[0034] (1) Weighing (NH 4 ) 6 Mo 7 o 24 ?4H 2 O0.30mmol, Ni(CH 3 COO) 2 ?4H 2 O2.10mmol, H 2 NCSNH 2 Add 8.40mmol and NaCl4.20mmol to 70mL ultrapure water, stir for 20min;

[0035] (2) Transfer the mixed solution to a reaction kettle with a volume of 100mL, and react at 180°C for 20h;

[0036] (3) After the reaction, cool to room temperature and centrifuge at a speed of 3000r / min for 4min. The centrifuged product is washed three times with ultrapure water, then washed three times with absolute ethanol, and dried in a vacuum oven at 60°C 12h;

[0037] (4) Place the dried product in a vacuum gas-filled tube furnace under N 2 Under the protection of , it was calcined at 400°C for 2h, and the heating rate was 4°C / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com