A laser shock life extension method for tungsten electrodes of short-arc lamps

A laser shock and tungsten electrode technology, which is applied in the manufacture of thermionic cathodes, etc., can solve the problems of short arc lamp filaments with low lifespan, low use efficiency, and high cost of use, to prevent the initiation of micro-cracks, improve service life, and improve stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

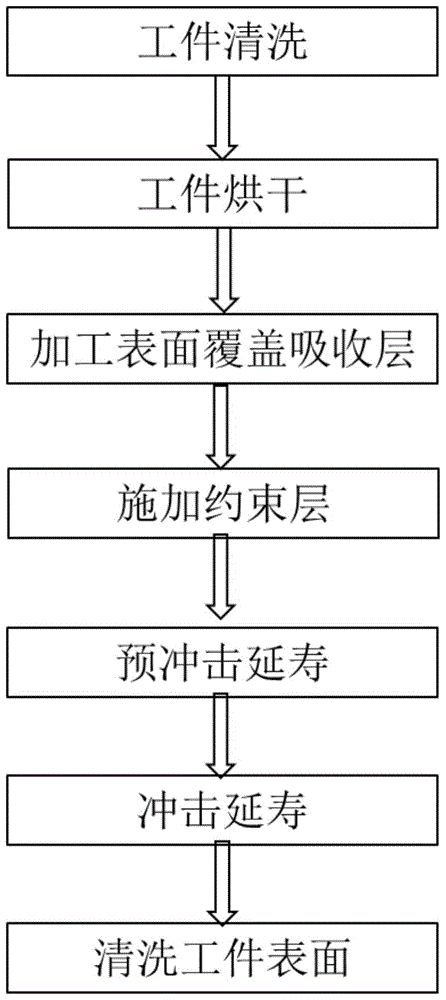

Method used

Image

Examples

Embodiment 1

[0034] Specimen material: 5000R tungsten electrode of short-arc mercury-xenon lamp from Shenzhen Kaishi Optoelectronics Technology Co., Ltd.;

[0035] Put the tungsten electrode into an ultrasonic cleaning machine equipped with deionized water at a temperature of 23°C, and the ultrasonic frequency is 40kHz, and clean for 9 minutes;

[0036] Blow dry with 0.6MPa dry nitrogen, and then put it in a drying oven at 100°C for 10 minutes;

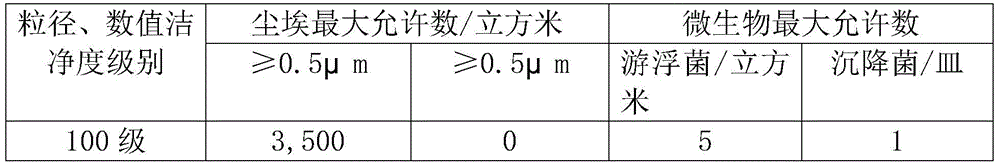

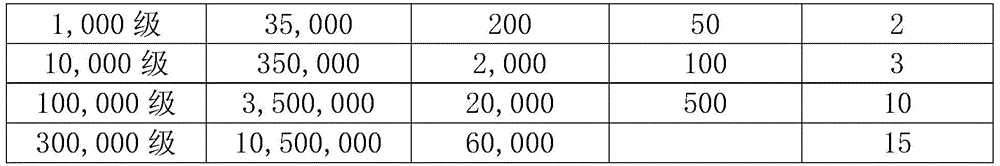

[0037] In the 10,000-class clean room, the working end face (front end) of the tungsten electrode is covered with a layer of black tape with a thickness of 120 μm for the absorption layer;

[0038] Install the tungsten electrode covered with the absorbing layer on the workbench, with the front end of the tungsten electrode facing the laser beam, and apply a constrained layer with a thickness of 2mm on the absorbing layer, and select deionized water for the constrained layer;

[0039] The laser beam with a pulse width of 12ns, a wavelength of 1064...

Embodiment 2

[0043] Specimen material: 5000R tungsten electrode of short-arc mercury-xenon lamp from Shenzhen Kaishi Optoelectronics Technology Co., Ltd.;

[0044] Put the tungsten electrode into an ultrasonic cleaning machine equipped with deionized water at a temperature of 23°C, and the ultrasonic frequency is 40kHz, and clean for 9 minutes;

[0045] Blow dry with 0.6MPa dry nitrogen, and then put it in a drying oven at 100°C for 10 minutes;

[0046] In the 10,000-class clean room, the working end face (front end) of the tungsten electrode is covered with an absorbing aluminum foil with a thickness of 120 μm;

[0047] Install the tungsten electrode covered with the absorbing layer on the workbench, with the front end of the tungsten electrode facing the laser beam, and apply a constrained layer with a thickness of 2.5 mm on the absorbing layer, and select deionized water for the constrained layer;

[0048] The laser beam with a pulse width of 17ns, a wavelength of 1064nm, a laser energ...

Embodiment 3

[0052] Specimen material: 5000R tungsten electrode of short-arc mercury-xenon lamp from Shenzhen Kaishi Optoelectronics Technology Co., Ltd.;

[0053] Put the tungsten electrode into an ultrasonic cleaning machine equipped with deionized water at a temperature of 23°C, and the ultrasonic frequency is 40kHz, and clean for 9 minutes;

[0054] Blow dry with 0.6MPa dry nitrogen, and then put it in a drying oven at 100°C for 10 minutes;

[0055] In a class 10,000 clean room, the working end face (front end) of the tungsten electrode is covered with a layer of black paint with a thickness of 120 μm for the absorption layer;

[0056] Install the tungsten electrode covered with the absorbing layer on the workbench, with the front end of the tungsten electrode facing the laser beam, and apply a constrained layer with a thickness of 3 mm on the absorbing layer. The constrained layer is made of K47 light-transmitting glass;

[0057] The laser beam with a pulse width of 20 ns, a waveleng...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com