Communication and lighting multiplex LED lamp

A technology of LED lamps and substrates, applied in lighting devices, fixed lighting devices, lighting and heating equipment, etc., can solve the problems of LED luminous efficiency attenuation, phosphor quantum efficiency reduction, etc., to achieve simple production, improve service life and luminescence Efficiency, the effect of simplifying the packaging process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] a. Preparation of fluorescent vitreous body

[0028] The content of the rare earth element doped in the luminescence center is 0-10 mol%, the content of the glass matrix is 100-90 mol%, and the mass sum of the above components is 100 mol%. Among them, the luminescent center is one or more rare earth ions (Dy 3+ 、Sm 3+ , Tb 3+ 、Eu 3+ 、Eu 2+ 、Ce 2+ 、Tm 3+ 、Ho 3+ etc.) and transition metal ions (Mn 2+ , Sn 4+ etc.); glass substrates include silicates, phosphates, borates, tellurates, etc. It is mainly prepared by high temperature melting method.

[0029] b. Preparation of fluorescent ceramic body

[0030] The amount of fluorescent micro-nano crystals doped with the luminescent center is 1-60 mol%, the glass matrix is 40-99 mol%, and the sum of the above components is 100 mol%. Among them, fluorescent micro-nano crystals are uniaxial crystals of cubic crystal phase (such as Y 2 o 3 , YAG, etc.), the luminescent center is one or more rare earth ions (Dy 3+...

Embodiment 1

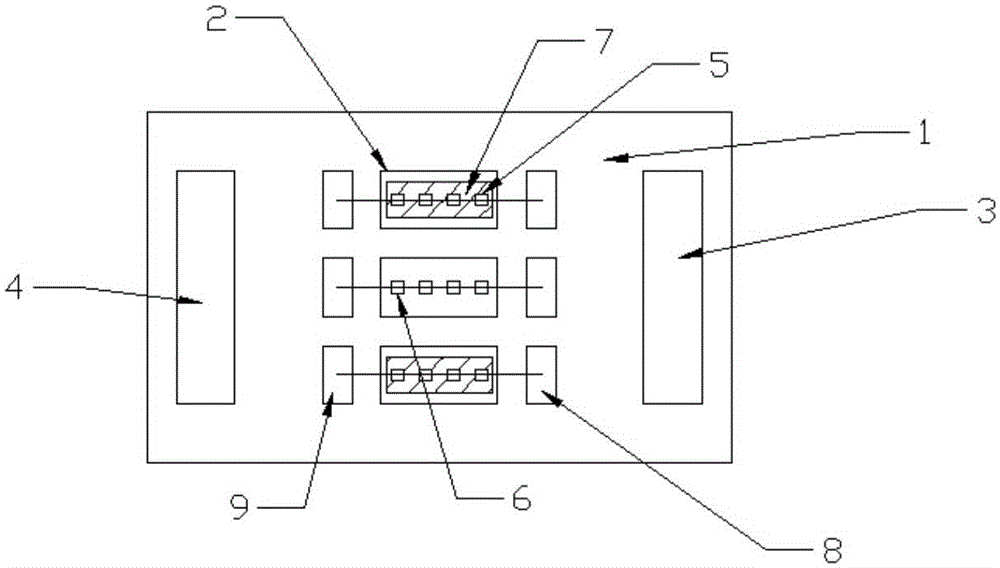

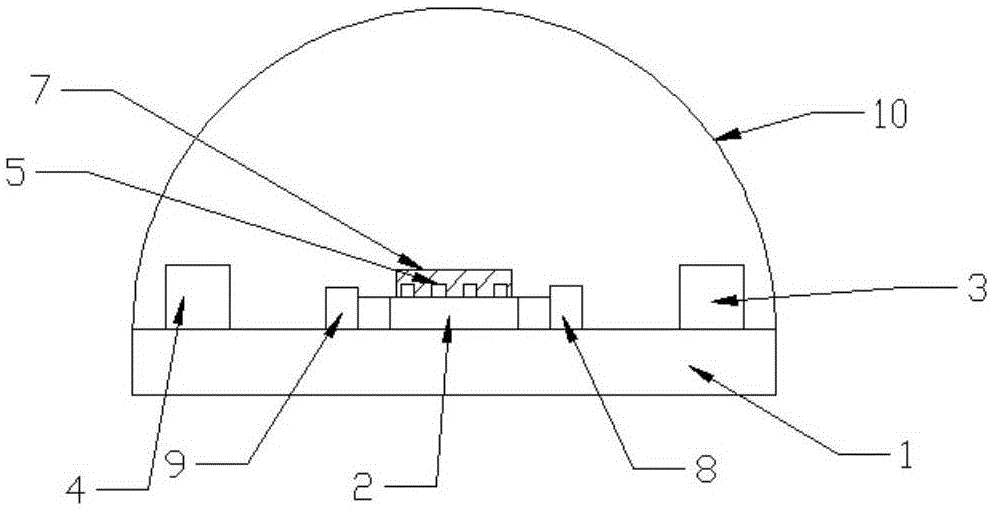

[0037] First, a transparent ceramic phosphor is prepared. The co-precipitation method was used to synthesize YAG:Ce fluorescent micro-nano crystals, the particle size of which was about 30-50nm. Weigh 20g of YAG:Ce fluorescent micro-nano crystals for later use. Then, 30 g of tellurite glass powder was prepared by high-temperature melting method, and the refractive index and dispersion of the glass were adjusted to match YAG:Ce by adjusting the ratio of glass components. The fluorescent micro-nano crystals and the glass matrix powder are mixed in proportion and placed in a crucible, and the glass matrix is melted in a furnace, fully stirred and then quenched to obtain a transparent ceramic phosphor. Finally, light-emitting structures of various sizes and shapes are processed according to lighting requirements (below figure 1 The phosphor 7 in the figure is a transparent phosphor sheet processed through grinding, polishing and other processes).

[0038] Then, on the substra...

example 2

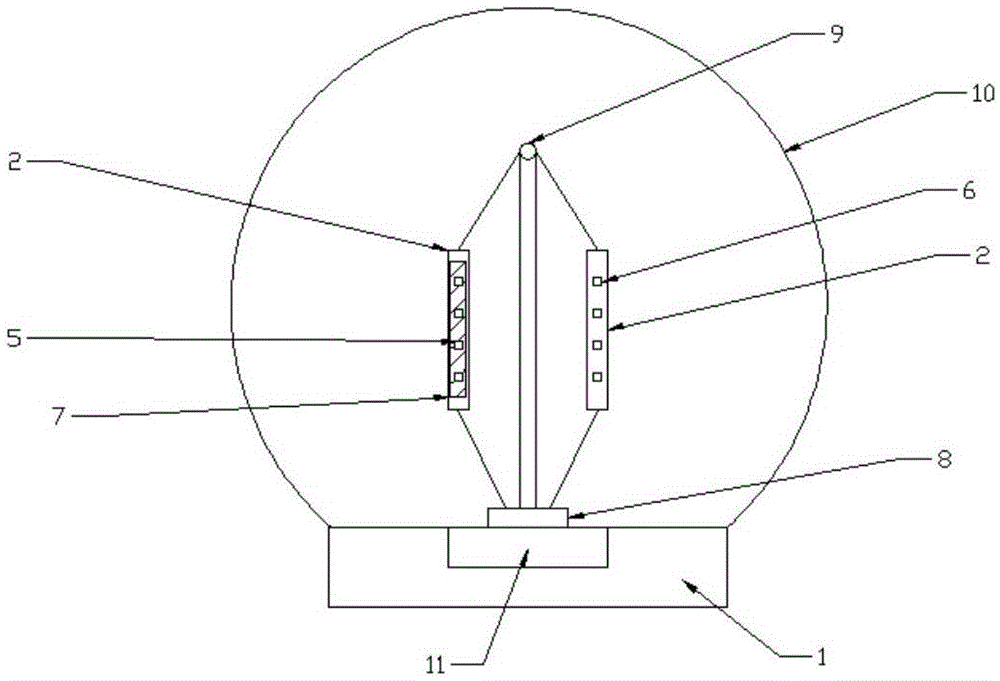

[0040] First, the glass phosphor is prepared by a high-temperature melting method. Raw material ratio is 41P 2 o 5 -17K 2 O-8Al 2 o 3 -20BaF 2 -3PbF 2 -10LiF-Dy 2 o 3 Weigh 25g of raw material, mix and shake well, and pour it into a 50ml quartz crucible; put the quartz crucible into a high-temperature furnace with a temperature of 1000°C and keep it warm for 1h; stir and shake well, then pour it into a 340°C copper mold to quench; put Annealed in a muffle furnace at 360°C for 5 hours. Finally, light-emitting structures of various sizes and shapes are processed according to lighting requirements (below image 3 The phosphor 7 in the figure is a transparent phosphor hollow tube that is post-processed through processes such as grinding, polishing, and tube extrusion).

[0041] Then, the substrate 2 is made into strips, so that chips can be inlaid on both sides of the substrate, thereby greatly improving resource utilization. Part of the substrate is used to inlay 360nm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com