Microorganism fertilizer for promoting crop growth and preparation method therefor

A technology that promotes plant growth and microbial fertilizers, applied in fertilizer mixtures, fertilization devices, applications, etc., can solve the problems of slow plant growth and increase speed, and achieve the effects of enhancing plant immunity, improving growth promotion, and promoting health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

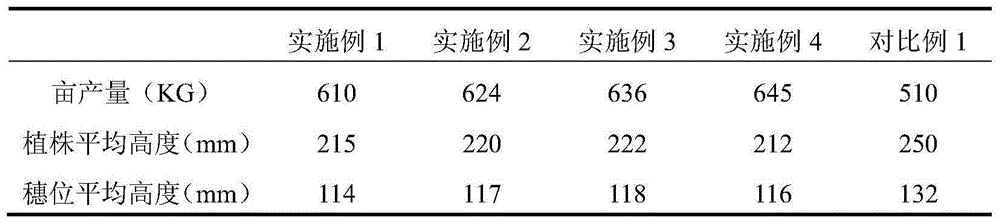

Examples

Embodiment 1

[0025] Weigh the following raw materials according to parts by mass: 100 parts of plant straw, 0.08 parts of 5A-hydroxylaxogenin, 0.04 parts of theobromine, 80 parts of chitosan hydrochloride, 1.2 parts of Bacillus subtilis bacterial agent, 10 parts of lactic acid bacteria powder, 8 parts of yeast powder, 20 parts of potassium dihydrogen phosphate, 10 parts of ferrous sulfate, 15 parts of calcium carbonate, 3 parts of magnesium chloride, 3 parts of ammonium molybdate, 3 parts of zinc sulfate, 3 parts of manganese sulfate, and 3 parts of boric acid. Its specific preparation method is as follows:

[0026] The Bacillus subtilis inoculant is added to the plant straw with a humidity of 50%, placed at 30° C., and aerobically fermented for 60 hours to obtain a microbial fermented material. Then, the above-mentioned microbial fermentation material is mixed with 5A-hydroxylaxogenin, theobromine, chitosan hydrochloride, Bacillus subtilis bacterial agent, lactic acid bacteria powder, yea...

Embodiment 2

[0028] The following raw materials were weighed in parts by mass: 100 parts of plant straw, 0.16 parts of 5A-hydroxylaxogenin, 0.10 parts of theobromine, 60 parts of chitosan hydrochloride, 0.8 parts of Bacillus subtilis bacterial agent, 6 parts of lactic acid bacteria powder, 4 parts of yeast powder, 8 parts of potassium dihydrogen phosphate, 6 parts of ferrous sulfate, 10 parts of calcium carbonate, 1 part of magnesium chloride, 1 part of ammonium molybdate, 1 part of zinc sulfate, 1 part of manganese sulfate, and 1 part of boric acid. Its specific preparation method is as follows:

[0029]Add the Bacillus subtilis inoculum, the Bacillus colloidus inoculum, and the Bacillus amyloliquefaciens inoculum into the plant straw with a humidity of 70%, place it at 40° C., and perform aerobic fermentation for 36 hours to obtain a microbial fermentation material. Then, the above-mentioned microbial fermentation material is mixed with 5A-hydroxylaxogenin, theobromine, chitosan hydrochl...

Embodiment 3

[0031] The following raw materials were weighed in parts by mass: 100 parts of plant straw, 0.12 parts of 5A-hydroxylaxogenin, 0.07 parts of theobromine, 80 parts of chitosan hydrochloride, 1.2 parts of Bacillus subtilis bacterial agent, 10 parts of lactic acid bacteria powder, 8 parts of yeast powder, 20 parts of potassium dihydrogen phosphate, 10 parts of ferrous sulfate, 15 parts of calcium carbonate, 3 parts of magnesium chloride, 3 parts of ammonium molybdate, 3 parts of zinc sulfate, 3 parts of manganese sulfate, and 3 parts of boric acid. Its specific preparation method is as follows:

[0032] Add the Bacillus subtilis inoculum, the Bacillus colloidus inoculum, and the Bacillus amyloliquefaciens inoculum into the plant straw with a humidity of 60%, place it at 35° C., and perform aerobic fermentation for 48 hours to obtain a microbial fermentation material. Then, the above-mentioned microbial fermentation material is mixed with 5A-hydroxylaxogenin, theobromine, chitosan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com