Microbial fertilizer for accelerating crop growth and preparation method for microbial fertilizer

A technology of microbial fertilizers and raw materials, applied in fertilizer mixtures, agriculture, fertilization devices, etc., can solve the problems of slow growth of plants, achieve the effects of enhancing plant immunity, promoting health, and increasing degradation rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

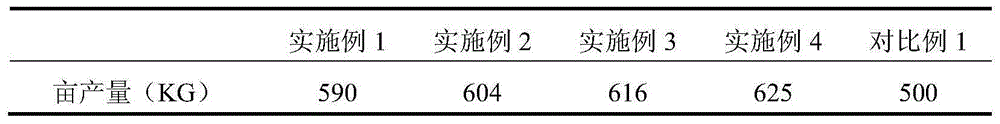

Examples

Embodiment 1

[0025] Weigh the following raw materials according to mass parts: 100 parts plant straw, 8 parts rhamnolipid, 4 parts nucleotide salt, 80 parts chitosan hydrochloride, 1.2 parts Bacillus subtilis inoculum, 10 parts lactic acid bacteria powder, 8 parts Parts of yeast powder, 20 parts of potassium dihydrogen phosphate, 10 parts of ferrous sulfate, 15 parts of calcium carbonate, 3 parts of magnesium chloride, 3 parts of ammonium molybdate, 3 parts of zinc sulfate, 3 parts of manganese sulfate, 3 parts of boric acid. The specific preparation method is as follows:

[0026] The Bacillus subtilis inoculum is added to plant straws with a humidity of 50%, and placed at 30° C. for aerobic fermentation for 60 hours to obtain microbial fermentation material. Then, the above-mentioned microbial fermentation material was combined with rhamnolipid, nucleotide salt, chitosan hydrochloride, Bacillus subtilis, lactic acid bacteria powder, yeast powder, potassium dihydrogen phosphate, ferrous sulfa...

Embodiment 2

[0028] Weigh the following raw materials according to mass parts: 100 parts of plant straw, 16 parts of rhamnolipids, 10 parts of nucleotide salts, 60 parts of chitosan hydrochloride, 0.8 parts of Bacillus subtilis inoculum, 6 parts of lactic acid bacteria powder, 4 parts Parts of yeast powder, 8 parts of potassium dihydrogen phosphate, 6 parts of ferrous sulfate, 10 parts of calcium carbonate, 1 part of magnesium chloride, 1 part of ammonium molybdate, 1 part of zinc sulfate, 1 part of manganese sulfate, 1 part of boric acid. The specific preparation method is as follows:

[0029] Adding Bacillus subtilis inocula, Bacillus mucilaginosa inocula, and Bacillus amyloliquefaciens inocula into plant straws with a humidity of 70%, placed at 40° C. for aerobic fermentation for 36 hours to obtain microbial fermentation material. Then, the above-mentioned microbial fermentation material was combined with rhamnolipid, nucleotide salt, chitosan hydrochloride, Bacillus subtilis, lactic acid ...

Embodiment 3

[0031] Weigh the following raw materials according to mass parts: 100 parts of plant straw, 12 parts of rhamnolipids, 7 parts of nucleotide salts, 80 parts of chitosan hydrochloride, 1.2 parts of Bacillus subtilis inoculum, 10 parts of lactic acid bacteria powder, 8 parts Parts of yeast powder, 20 parts of potassium dihydrogen phosphate, 10 parts of ferrous sulfate, 15 parts of calcium carbonate, 3 parts of magnesium chloride, 3 parts of ammonium molybdate, 3 parts of zinc sulfate, 3 parts of manganese sulfate, 3 parts of boric acid. The specific preparation method is as follows:

[0032] Adding Bacillus subtilis inocula, Bacillus mucilaginous inocula, and Bacillus amyloliquefaciens inocula into plant straws with a humidity of 60%, and placed at 35° C. for aerobic fermentation for 48 hours to obtain microbial fermentation material. Then, the above-mentioned microbial fermentation material was combined with rhamnolipid, nucleotide salt, chitosan hydrochloride, Bacillus subtilis, l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com