Method for extracting and purifying monomeric macamide compounds from maca

A technology for purifying macamide and compounds, which is applied in the separation/purification of carboxylic acid amides, organic chemistry and other directions, can solve the problems of a large-scale preparation method without macamide monomer compounds, etc., and achieves low cost, improved extraction rate, and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Plant maca is crushed into 40-60 mesh maca powder, weighs 120 grams of maca powder, puts it into a multi-stage countercurrent extraction device, and then adds 1200ml of 80% ethanol-acetic acid aqueous solution for countercurrent extraction for 5 hours, after extraction Filter, concentrate under vacuum (0.05-0.1MPa), and concentrate under reduced pressure at about 50°C to obtain 17.8 grams of crude macamide.

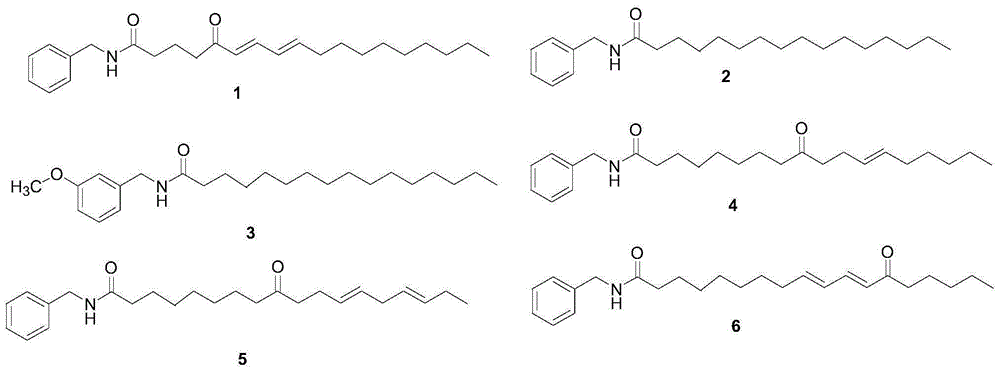

[0023] Take a glass chromatographic column with a column length of 450mm and an inner diameter of 45mm, install 350ml of D101 macroporous adsorption resin, load the above-mentioned crude product of macamide on the top of the chromatographic column, and then use mobile phases of 50%, 60%, and 70% , 80%, 90% ethanol-water solution for gradient elution, TLC plate tracking, concentrated under vacuum (0.05-0.1MPa), and water with absolute ethanol to obtain 64mg of N-benzyl-5-oxo-6E ,8E-octadecadienamide (purity 97.3%), 31mgN-benzyl-hexadecanamide (purity 95.8%), 25mgN-(...

Embodiment 2

[0032] Plant maca is pulverized into 40-60 mesh maca powder, takes by weighing 120 grams of plant maca powder, packs in the multistage countercurrent extraction device, then adds 80% ethanol-glycine aqueous solution of 1200ml, carries out multistage countercurrent extraction 4 After 1 hour, the extract was filtered, and the filtrate was concentrated under vacuum (0.05-0.1 MPa), and concentrated under reduced pressure at about 55° C. to obtain 16.5 grams of crude plant macamide.

[0033] Take a glass chromatographic column with a column length of 450 mm and an inner diameter of 45 mm, and install 250 ml of DM301 macroporous adsorption resin, load the above-mentioned crude macamide sample on the top of the column, and then use mobile phases of 50%, 60%, and 70% respectively. %, 80%, 90% ethanol-water solution for gradient elution, followed by TLC plate, concentrated under vacuum (0.05-0.1MPa), and brought water with absolute ethanol to obtain 57mg N-benzyl-5-oxo- 6E, 8E-octadeca...

Embodiment 3

[0035] The plant maca medical material is crushed into 40-60 mesh maca powder, 120 grams of macamide powder is weighed, packed into a multistage countercurrent extraction device, and then 1200ml of 80% ethylene propanol-phosphoric acid aqueous solution is added to carry out multiple extractions at room temperature. Stage countercurrent extraction for 2 hours, the extract was taken out and filtered, the filtrate was concentrated under vacuum (0.05-0.1MPa), and concentrated under reduced pressure at about 30°C to obtain 14.3 grams of crude macamide.

[0036] Take a glass chromatographic column with a column length of 450 mm and an inner diameter of 45 mm, and install 350 ml of DA-201 macroporous adsorption resin, load the above-mentioned crude product of macamide on the top of the column, and then use mobile phases of 50%, 60%, and 70%, 80%, 90% ethanol-water solution for gradient elution, TLC plate tracking, concentration under vacuum (-0.6-0.1MPa), and water with absolute ethan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com