A preparation method and application of magnetic organic conjugated polymer microspheres

A technology of conjugated polymers and microspheres, applied in chemical instruments and methods, and other chemical processes, can solve problems such as poor adsorption effect and poor deep purification ability, and achieve fast speed, large adsorption capacity, and high removal efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1 Synthesis of product

[0034] 1. Synthesis: 150mg of nanometer Fe 3 O 4 The ball is placed in a 50ml dry round bottom flask, 5ml toluene and 5ml triethylamine are added to the device, and vigorously stirred under argon atmosphere to form a suspension. Then, 6mmol of 1,4-diethynylbenzene, 4mmol of 2,4,6-tribromophenol, 100mg of tetrakis(triphenylphosphine)palladium, and 30mg of cuprous iodide were added to the solution. Then the temperature was raised to 80°C and reacted for 10 hours.

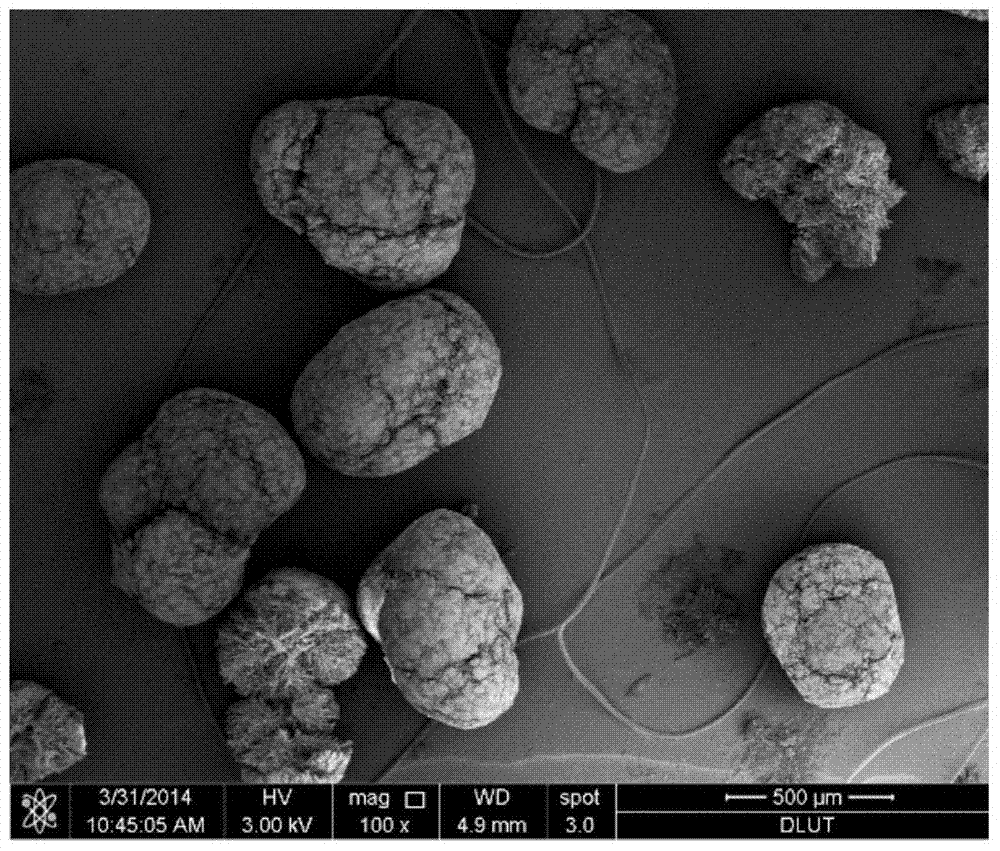

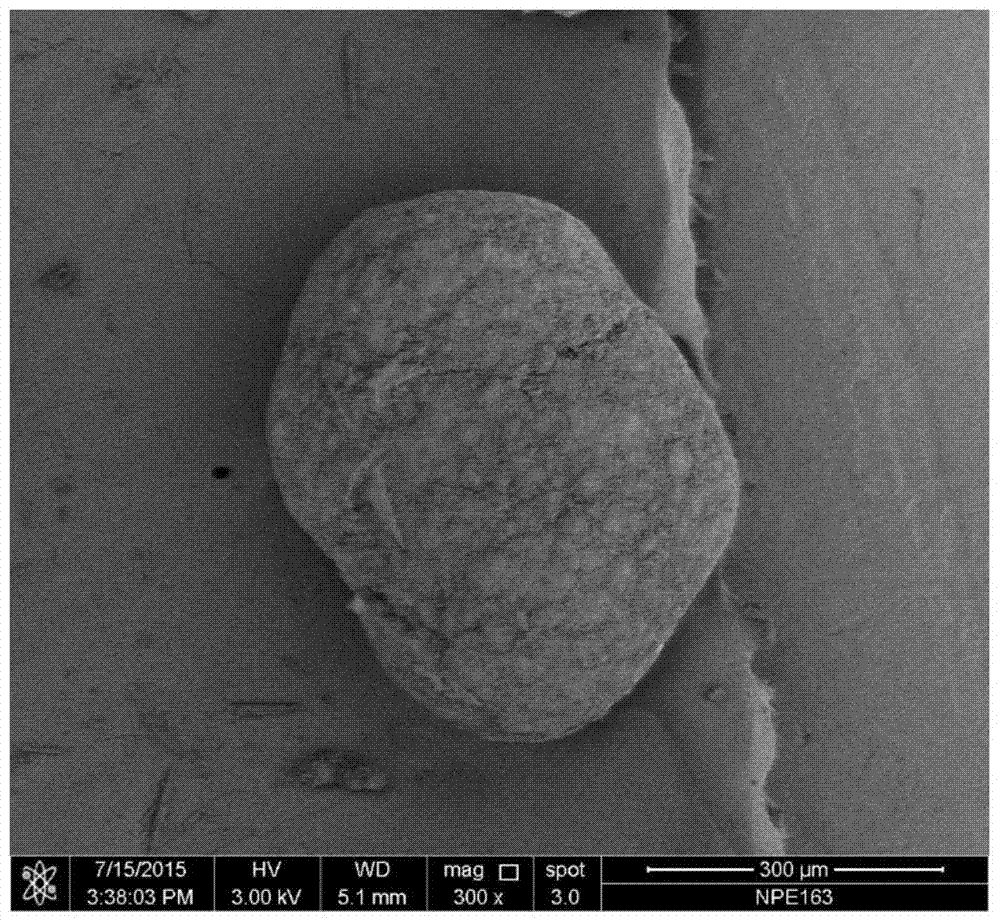

[0035] 2. Washing: Wash the product with ethanol and filter. Then use a fully automatic extractor to clean with methanol as the extraction liquid. Vacuum and dry for 3 hours at 100°C. Magnets are used to absorb large particles of polymer materials to obtain coated magnetic Fe 3 O 4 The organic conjugated polymer microspheres1.

Embodiment 2

[0036] Example 2 Synthesis of product

[0037] 1. Synthesis: 300mg of nanometer Fe 3 O 4 The ball was placed in a 100ml dry round bottom flask, 15ml toluene and 15ml triethylamine were added to the device, and vigorously stirred under nitrogen to form a suspension. Then 9mmol of 1,4-diethynylbenzene, 7mmol of 2,4,6-tribromoaniline, 300mg of tetrakis(triphenylphosphine)palladium, and 60mg of cuprous iodide were added to the solution. Then the temperature was raised to 80°C and reacted for 10 hours.

[0038] 2. Washing: Wash the product with ethanol and filter. Then use a fully automatic extractor to clean with methanol as the extraction liquid. Vacuum and dry for 3 hours at 100°C. Use magnet to absorb, can get wrapped magnetic Fe 3 O 4 的organic conjugated polymer microspheres2.

Embodiment 3

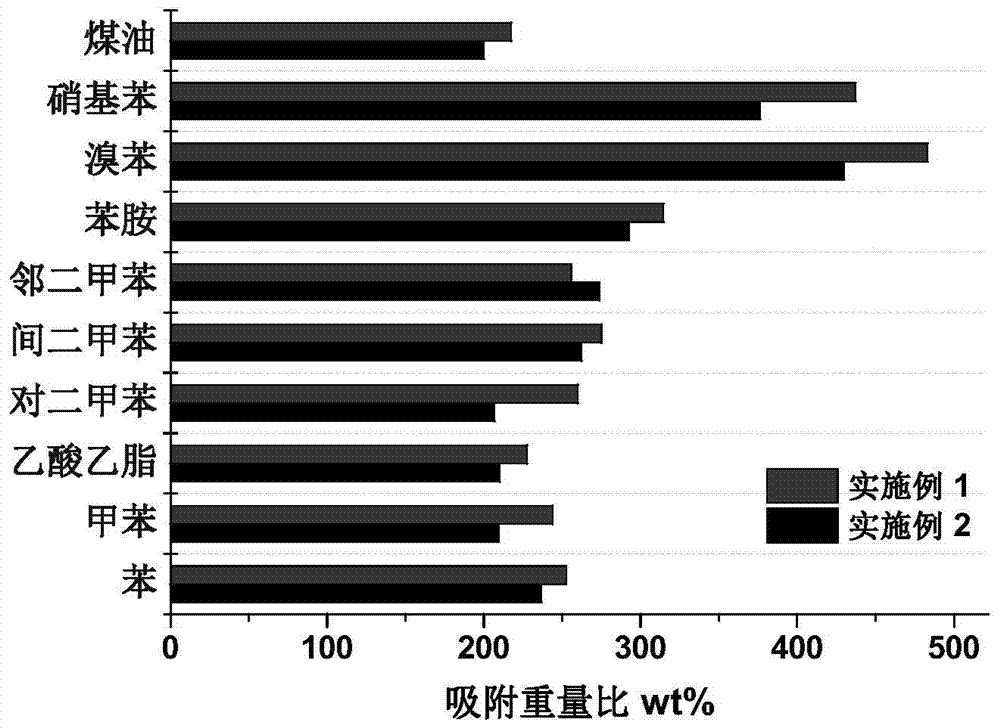

[0039] Example 3 Product Evaluation

[0040] 1. Detection of the material's ability to adsorb organic matter:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com