Self-healing nano conductive polymer material and preparation method thereof

A polymer material and nano-conductive technology, which is applied in the field of self-repairing nano-conductive polymer materials and its preparation, can solve problems such as unsatisfactory and unusable, and achieve adjustable strength, good economic and social benefits, and good compatibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 12.5 g of liquid polysulfide rubber with thiol groups and 12.5 g of bisphenol A epoxy resin containing 0.06 gram equivalent per 100 gram of hydroxyl were weighed respectively. 12.5 g of bisphenol A epoxy resin was placed in a three-necked flask and heated to 25°C. Then 12.5 g of liquid polysulfide rubber with thiol groups was slowly added dropwise into the three-necked flask within 20 min. The stirring speed is 250 rpm. After stirring for 15 min, 4 mL of 15% NaOH aqueous solution was slowly dropped into the three-necked flask and stirred for a further 15 min. The above liquid was heated to 120°C and stirring was continued for 1 h. Then 12.5 g of spherical nano-Ag was added into the three-necked flask, while ultrasonically oscillating for 5 min. 2.5 g of diethylenetriamine, 0.85 g of cetyltrimethylammonium bromide and 0.8 g of sodium hydroxide were added to the above mixed solution and stirred for 3 min. The product was moved to a 3 mm thick mold, heated to 60°C, and...

Embodiment 2

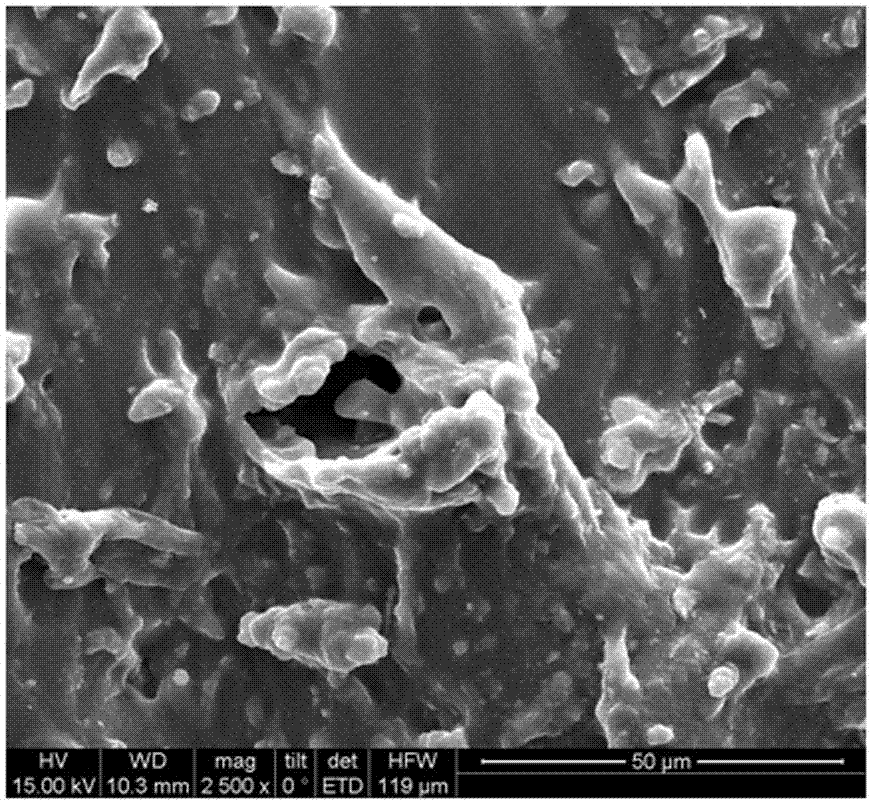

[0029] Weigh 15 g of liquid polysulfide rubber with thiol groups and 45 g of bisphenol A epoxy resin containing 0.15 gram equivalent per 100 gram of hydroxyl groups. Put the bisphenol A epoxy resin in a three-necked flask and heat it to 50°C. Then, the liquid polysulfide rubber with thiol groups was slowly added dropwise into the three-necked flask within 20 min. The stirring speed is 150 rpm. After stirring for 25 min, 5 mL of 20% NaOH aqueous solution was slowly dropped into the three-necked flask and stirred for a further 30 min. The above liquid was heated to 140°C and stirring was continued for 2 h. Then 42 g of porous nano-metal cobalt was added into the three-necked flask, while ultrasonically vibrating for 10 min. 6 g of diethylenetriamine, 0.2 g of cetyltrimethylammonium bromide and 0.8 g of sodium hydroxide were added to the above mixed solution and stirred for 10 min. The product was moved to a 4 mm thick mold, heated to 80 °C, and kept for 1.5 h for curing to o...

Embodiment 3

[0031]Weigh 25 g of liquid polysulfide rubber with thiol groups and 20 g of bisphenol A epoxy resin containing 0.20 g equivalent / 100 g of hydroxyl groups. Put the bisphenol A epoxy resin in a three-necked flask and heat it to 60°C. Then 25 g of liquid polysulfide rubber with thiol groups was slowly added dropwise into the three-necked flask within 25 min. The stirring speed is 200 rpm. After stirring for 30 min, 8 mL of 25% NaOH aqueous solution was slowly dropped into the three-necked flask and stirred for a further 35 min. The above liquid was warmed to 150 °C and continued to stir for 3 h. Then 35 g of spherical nano-metal Fe-CO alloy was added into the three-necked flask, while ultrasonically vibrating for 3 min. Add 6 g of hexahydrophthalic anhydride, 1.8 g of cetyltrimethylammonium bromide and 1.2 g of urea into the above mixed solution and stir for 15 min. The product was moved to a mold with a thickness of 8 mm, heated to 100 °C, and kept for 10 h for curing to obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com