A wear-resistant, mildew-proof and non-stick pan coating

A non-stick pan and coating technology, used in coatings, anti-corrosion coatings, anti-fouling/underwater coatings, etc., can solve the problems of easy peeling, reduced non-stick performance, dry burning, etc., to achieve stable chemical properties and service life. long, damage-free effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

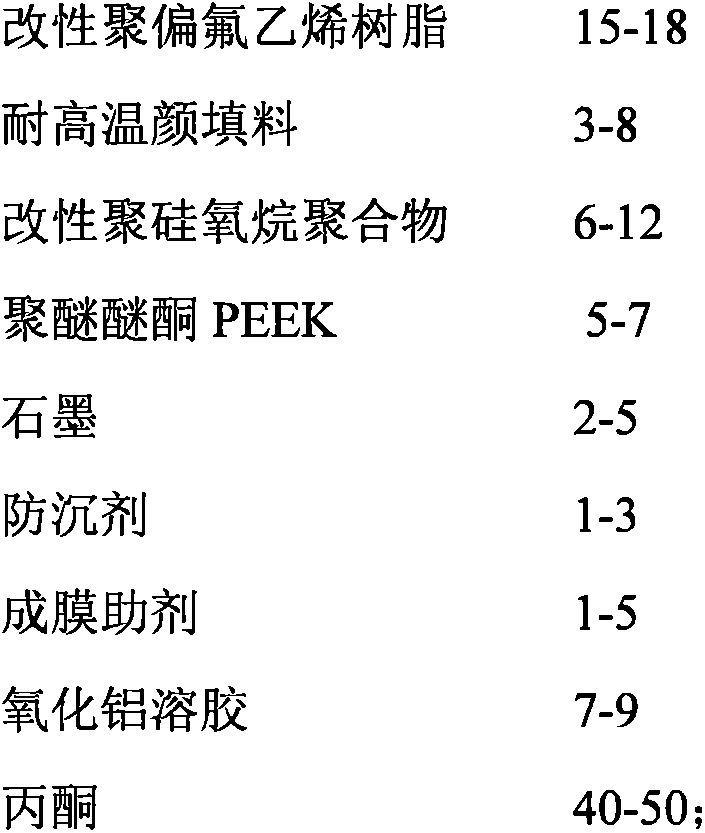

[0023] A wear-resistant, anti-mildew and non-stick pan coating comprises a primer and a surface layer; the primer is composed of the following raw materials in parts by weight:

[0024]

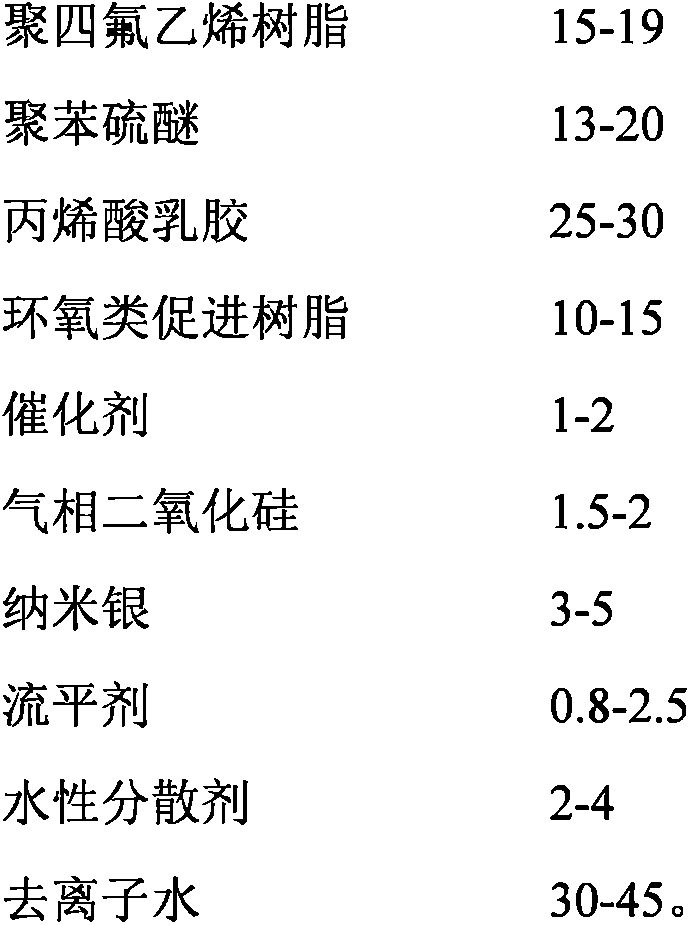

[0025] Described surface coating is made up of the raw material of following parts by weight:

[0026]

[0027]

[0028] Wherein, the modified polyvinylidene fluoride resin is composed of acrylic acid-based resin, polyvinylidene fluoride resin, methyl methacrylate, and acrylic acid. The high temperature resistant pigment is enamel black. The acrylic-containing resin is composed of methyl methacrylate, methacrylic acid, acrylic acid, ethylhexyl acrylate and methacrylamide.

Embodiment 2

[0030] A wear-resistant, anti-mildew and non-stick pan coating comprises a primer and a surface layer; the primer is composed of the following raw materials in parts by weight:

[0031]

[0032] Described surface coating is made up of the raw material of following parts by weight:

[0033]

[0034]

[0035] Wherein, the modified polyvinylidene fluoride resin is composed of acrylic acid-based resin, polyvinylidene fluoride resin, methyl methacrylate, and acrylic acid. The high temperature resistant pigment is enamel black. The acrylic-containing resin is composed of methyl methacrylate, methacrylic acid, acrylic acid, ethylhexyl acrylate and methacrylamide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com