Negative ion ceramic product adopting fly ash as main raw material, and preparation method thereof

A technology for main raw materials and ceramic products, applied in the field of negative ion ceramic products and their preparation, can solve the problems of impurity cannot be removed, affect the environment, waste of resources, etc., and achieve the effects of good color development, pollution reduction, and power consumption reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] A kind of preparation method taking fly ash as the negative ion ceramic brick of main raw material, comprises the following steps:

[0043]A. Raw material crushing and sieving: mix and crush fly ash, bone ash, clinker, plastic clay, flux and ceramic coloring material according to the ratio, and sieve for later use;

[0044] B. Batching and stirring powder: add water to the sifted powder and stir, and add auxiliary materials and negative ion powder according to the formula ratio during the stirring process;

[0045] C. Stale: Send the powder obtained in step B into the silo to stale;

[0046] D. Compression molding and drying: the stale powder is punched and formed to obtain bricks, and the bricks are sent to a roller kiln at 120-240°C for drying. The moisture after drying is controlled at 0.3-1%, so that the bricks can be obtained good enough strength;

[0047] E. Firing: Send the dried bricks into the kiln for firing.

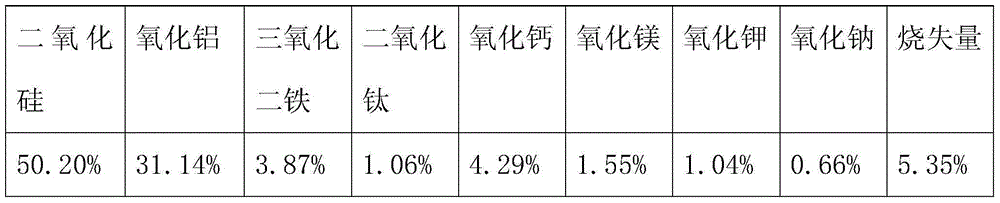

[0048] Wherein, in step A, the raw materials a...

Embodiment 1

[0061] The body of the ceramic thin-slab brick is made of the following raw materials in mass percentage: fly ash 50%, bone ash 20%, refractory waste brick 10%, borax 5%, bentonite 5%, reinforcing agent 0.1%, water reducing agent 0.1%, Praseodymium yellow 4.8%, negative ion powder 5%.

[0062] Preparation:

[0063] A. Raw material crushing and sieving: The raw materials fly ash, bone ash, refractory waste brick, borax, bentonite, and ceramic coloring material required by the formula are respectively crushed and passed through a 20-mesh standard sieve. The coarser particle raw materials are crushed again until the particle size reaches the standard, and they are put into storage together;

[0064] B. Batching, mixing and milling: mix the crushed qualified granular raw materials according to the formula ratio, add water and stir for 10 minutes, the stirring speed is 20r / min, and the amount of water added is controlled at 8% of the total raw materials. During the stirring proces...

Embodiment 2

[0072] The body of the ceramic thin-slab brick is made of the following raw materials in mass percentage: fly ash 50%, bone ash 10%, refractory waste brick 20%, borax 6%, bentonite 10%, reinforcing agent 0.5%, water reducing agent 0.5%, Ceramic pigment 2%, negative ion powder 1%, wherein the ceramic pigment is a combination of reddish brown and orange.

[0073] Preparation method Add water and stir for 20 minutes after removing the ingredients, the stirring speed is 20r / min, the amount of water added is controlled at 12% of the total amount of raw materials, the drying temperature is 200°C, the moisture after drying is controlled at 1%, and the thickness of the decorative layer is 0.2mm , The sintering temperature is 1180° C., and the sintering cycle is 40min, and the others are the same as in Example 1.

[0074] After performance testing, the permeable ceramic thin-slab brick prepared in this embodiment has a thickness of 4mm, a modulus of rupture of 40, a water absorption ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com