A kind of preparation technology of cobalt dicene

A preparation process and technology of cobaltene, which is applied in the field of preparation technology of metal compound cobaltene, can solve problems such as unmentioned product purity, and achieve the effects of low production cost, wide source, simple and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

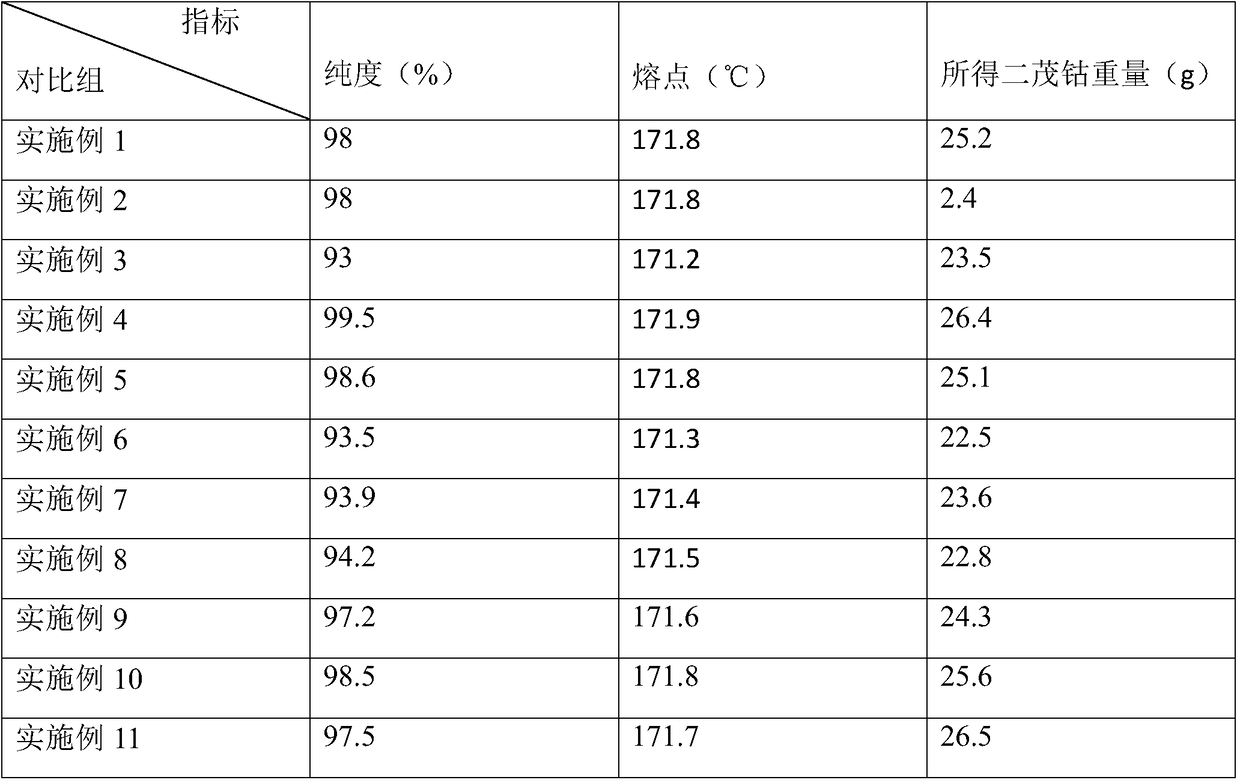

Examples

Embodiment 1

[0030] 1) Add 97.79ml of methanol dropwise to 41.58g of sodium methoxide, and use nitrogen gas bubbling for 5 minutes to remove the oxygen in the solvent. During the dropwise addition, the solution is cooled and the temperature is maintained at 40°C. Then add a mixed solution of 20 g of anhydrous cobalt dichloride and 63.91 ml of methanol, feed for about 15 minutes, continue to stir for 30 minutes, and react for 5 hours to obtain a methanol solution mixture of anhydrous cobalt methoxide;

[0031] 2) Add 32.95ml of cyclopentadiene monomer and 33.11ml of methanol solution dropwise at 40-45°C, feed for about 30 minutes, and then stir for about 5 hours to obtain a methanol mixture of cobaltocene;

[0032] 3) Rotate the mixed solution to remove the solvent to obtain the crude cobalt dicene, add 100ml of toluene to the crude product, after repeated shaking, filter and recover the filtrate, then spin off the filtrate, add 150ml of petroleum ether, reflux for a while, spin off half of ...

Embodiment 2

[0034] 1) 10ml of ethanol was added dropwise into 5.24g of sodium ethoxide, and the oxygen in the solvent was removed by bubbling nitrogen gas for 5 minutes. During the dropwise addition, the solution was cooled and the temperature was maintained at 40°C. Then add a mixed solution of 2 g of anhydrous cobalt dichloride and 8 ml of ethanol, continue the feeding for about 15 minutes, continue stirring for 30 minutes, and react for 5 hours to obtain an ethanolic solution mixture of cobalt in anhydrous alcohol.

[0035] 2) Add 3.3ml of cyclopentadiene and 4ml of ethanol solution dropwise at 45-50°C for 30 minutes, and then stir for 5 hours to obtain a mixture of cobaltocene and ethanol;

[0036] 3) Rotate the mixed solution to remove the solvent, add 10ml of toluene to the residue, and after repeated shaking, filter and recover the filtrate, then spin off the filtrate, add 8ml of petroleum ether, reflux for a while, then cool, and crystallize in an ice-water bath , and filtered the...

Embodiment 3

[0038] The difference from Example 1 is that the reaction temperature in Step 1 is 30°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com