Polyformaldehyde composite with surface capable of being finished and preparation method thereof

A composite material and polyoxymethylene technology, which is applied in the field of polyoxymethylene, can solve the problems of increasing the cost of producing products, changing the performance of the POM matrix, and increasing the production process of the products, so as to improve the mechanical properties, improve the paintability, and be easy to industrialized production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

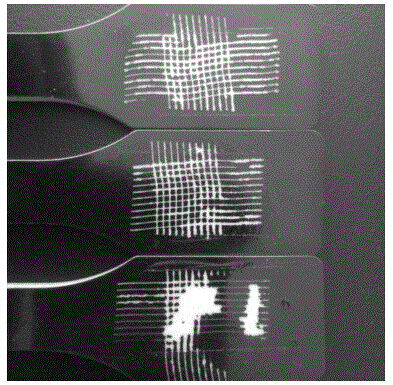

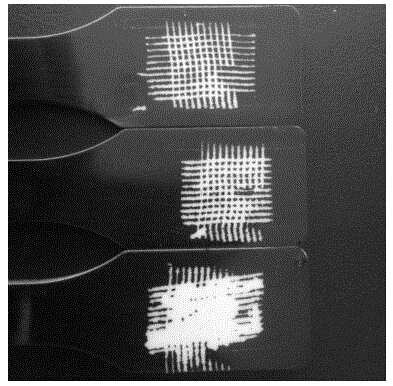

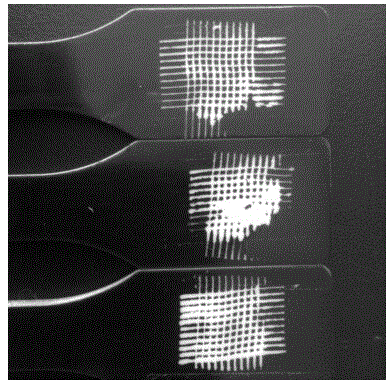

Image

Examples

Embodiment 1

[0022] One, a polyoxymethylene composite material that can be painted on the surface, comprising the following components by weight: 82 parts of polyoxymethylene POM, 12 parts of thermoplastic phenolic resin, 1 part of polyurethane thermoplastic elastomer TPU, 5 parts of silicon dioxide and 0.5 part of anti- Oxidizing agent 1010. The melt index of the polyoxymethylene POM is 9g / 10min, and the tensile strength is 58Mpa.

[0023] Two, the preparation method of the polyoxymethylene composite material that can be painted on the above-mentioned surface, comprises the steps:

[0024] 1) Weigh the ingredients of the above-mentioned parts by weight and knead them in a high mixer for 7 minutes, then send the uniformly mixed materials into a twin-screw extruder for extrusion and granulation; wherein, the twin-screw extruder starts from the feed The temperature of each section between the mouth and the extrusion mouth is: the first zone 110°C, the second zone 170°C, the third zone 200°C...

Embodiment 2

[0028] 1. A polyoxymethylene composite material that can be painted on the surface, comprising the following components by weight: 75 parts of polyoxymethylene POM, 15 parts of thermoplastic phenolic resin, 10 parts of polyvinyl alcohol PVA, 10 parts of calcium carbonate and 0.5 part of antioxidant 1010. The melt index of the polyoxymethylene POM is 8g / 10min, and the tensile strength is 60Mpa.

[0029] Two, the preparation method of the polyoxymethylene composite material that can be painted on the above-mentioned surface, comprises the steps:

[0030] 1) Weigh the ingredients of the above-mentioned parts by weight and knead them in a high mixer for 7 minutes, then send the uniformly mixed materials into a twin-screw extruder for extrusion and granulation; wherein, the twin-screw extruder starts from the feed The temperature of each section between the mouth and the extrusion mouth is: 115°C in the first zone, 160°C in the second zone, 190°C in the third zone, 210°C in the fou...

Embodiment 3

[0034] One, a polyoxymethylene composite material that can be painted on the surface, comprising the composition of following parts by weight: 75 parts of polyoxymethylene POM, 15 parts of thermoplastic phenolic resin, 8 parts of polyvinyl alcohol PVA, 4 parts of polyolefin type thermoplastic elastomer TPE, 4 parts 1 part silicone rubber, 4 parts quartz sand and 0.5 part antioxidant 1010. The melt index of the polyoxymethylene POM is 10g / 10min, and the tensile strength is 62Mpa.

[0035] Two, the preparation method of the polyoxymethylene composite material that can be painted on the above-mentioned surface, comprises the steps:

[0036] 1) Weigh the ingredients of the above-mentioned parts by weight and knead them in a high mixer for 7 minutes, then send the uniformly mixed materials into a twin-screw extruder for extrusion and granulation; wherein, the twin-screw extruder starts from the feed The temperature of each section between the mouth and the extrusion mouth is: 120°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com