Superhydrophobic coating containing poss block acrylate copolymer and preparation method thereof

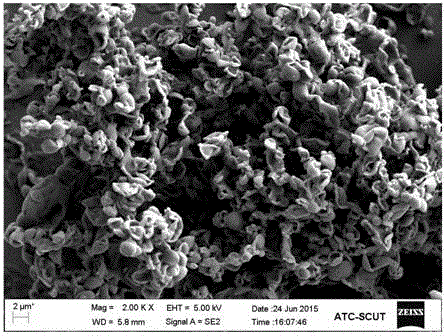

A super-hydrophobic coating and acrylate technology, applied in the field of polymer materials and surface science, to achieve the effect of promoting the development of surface roughness, excellent super-hydrophobic performance, and excellent self-cleaning performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

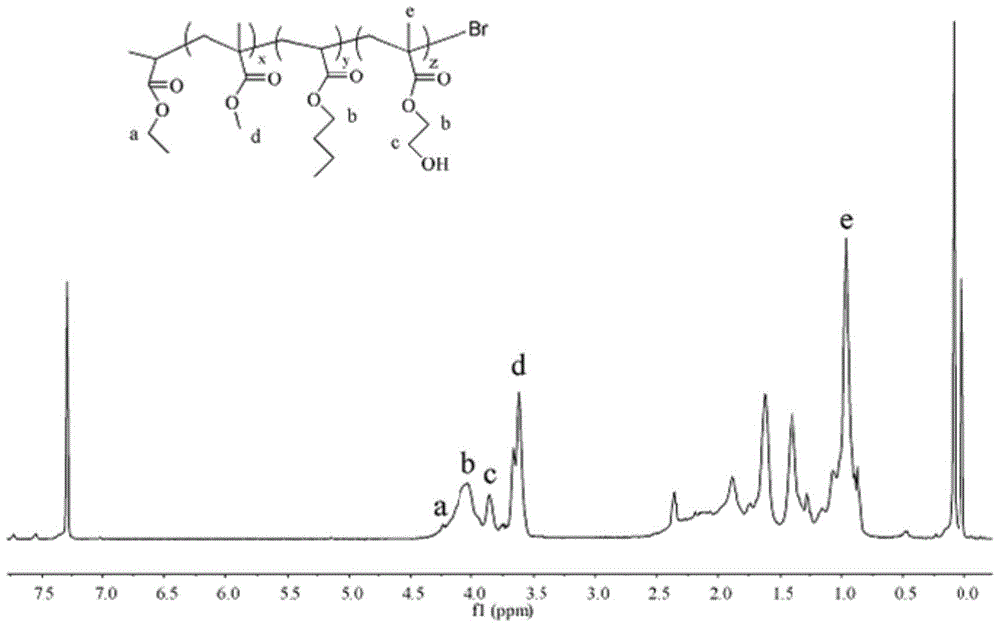

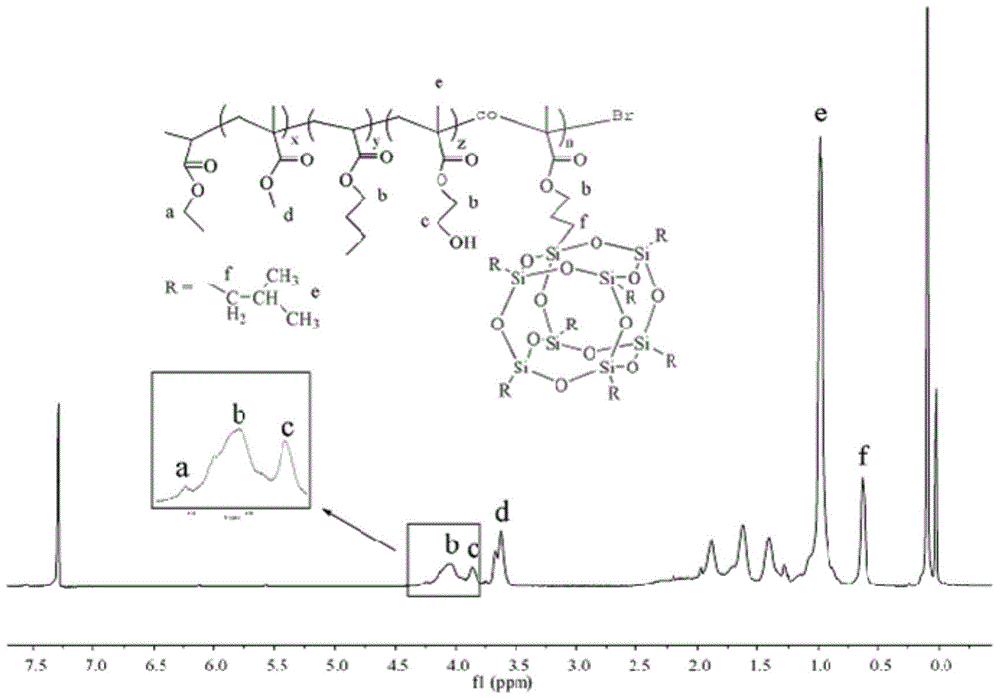

[0045] 1) Preparation of POSS-containing block acrylate copolymer

[0046] Atom transfer radical polymerization (ATRP) was used to prepare POSS-containing acrylate block copolymers: first, 3.7 mL of methyl methacrylate (MMA), 6.2 mL of butyl acrylate (BA), 1.7 mL of Hydroxyethyl methacrylate (HEMA), 7 mL solvent cyclohexanone, 244 µL ligand N,N,N',N",N"–pentamethyldiethylenetriamine (PMDETA), 102 µL initiator abromopropyl Ethyl acetate (EPN‐Br) and 0.0777g catalyst cuprous chloride (CuCl), the reaction system was frozen in liquid nitrogen-vacuumize-thaw cycle 5 times to remove oxygen, and then the reaction system was heated at 70°C under the protection of argon atmosphere. After reacting at high temperature for 16 hours, the obtained product was washed and precipitated three times with excess petroleum ether after cooling, and dried in a vacuum oven for three days to constant weight to obtain a macromolecular initiator. 2.8g of the macroinitiator was dissolved in a reaction f...

Embodiment 2

[0059] 1) Preparation of POSS-containing block acrylate copolymer

[0060] Atom transfer radical polymerization (ATRP) was used to prepare POSS-containing acrylate block copolymers: first, 3.7 mL of methyl methacrylate (MMA), 6.2 mL of butyl acrylate (BA), 1.7 mL of Hydroxyethyl methacrylate (HEMA), 7 mL solvent cyclohexanone, 491 µL ligand N,N,N',N",N"–pentamethyldiethylenetriamine (PMDETA), 205 µL initiator abromopropyl Ethyl acetate (EPN‐Br) and 0.1566g catalyst cuprous chloride (CuCl), the reaction system was frozen in liquid nitrogen-vacuumize-thaw cycle 5 times to remove oxygen, and then the reaction system was heated at 70°C under the protection of argon atmosphere. After reacting at high temperature for 16 hours, the obtained product was washed and precipitated three times with excess petroleum ether after cooling, and dried in a vacuum oven for three days to constant weight to obtain a macromolecular initiator. 2.8g of macroinitiator was dissolved in a reaction flask...

Embodiment 3

[0070] 1) Preparation and characterization of POSS-containing block acrylate copolymer

[0071]Atom transfer radical polymerization (ATRP) was used to prepare POSS-containing acrylate block copolymers: first, 3.7 mL of methyl methacrylate (MMA), 6.2 mL of butyl acrylate (BA), 1.7 mL of Hydroxyethyl methacrylate (HEMA), 7 mL solvent cyclohexanone, 146 µL ligand N,N,N',N",N"–pentamethyldiethylenetriamine (PMDETA), 61 µL initiator abromopropyl Ethyl acetate (EPN-Br) and 0.0466g catalyst cuprous chloride (CuCl), the reaction system was frozen in liquid nitrogen-vacuumize-thaw cycle 5 times to remove oxygen, and then the reaction system was heated at 70°C under the protection of argon atmosphere. After reacting at high temperature for 16 hours, the obtained product was washed and precipitated three times with excess petroleum ether after cooling, and dried in a vacuum oven for three days to constant weight to obtain a macromolecular initiator. 3.29g macroinitiator was dissolved in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com