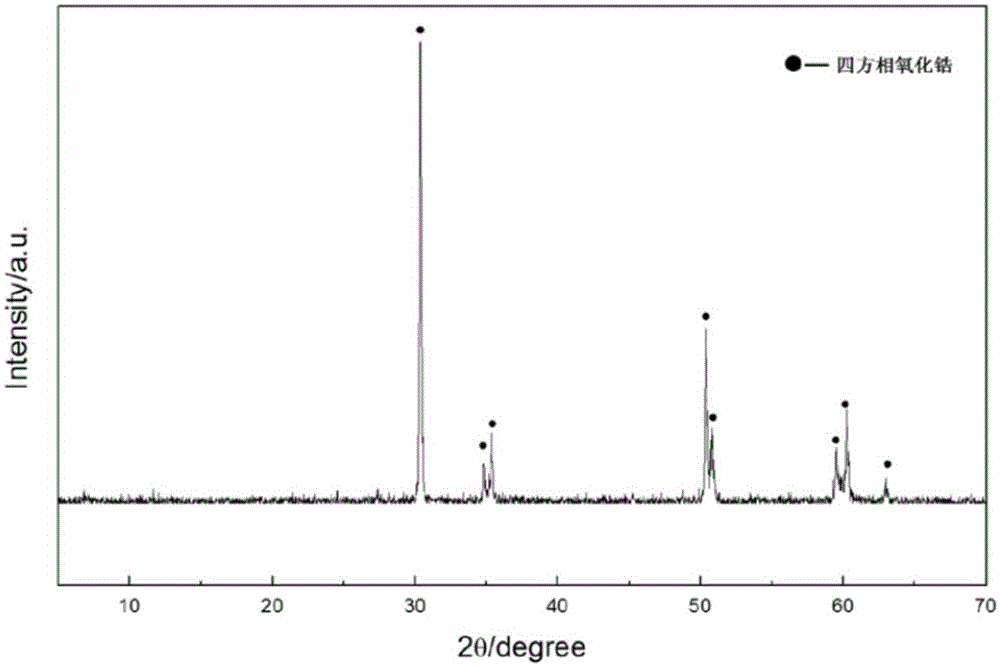

Method for preparing zirconia nanofiber by utilizing electrospinning technology and product prepared by same

An electrospinning technology and nanofiber technology, applied in the field of inorganic oxide fibers, can solve the problems affecting product performance and quality, complicated spinning solution preparation steps, and high raw material cost, improve performance and quality, and solve residual chloride ions. effect, the effect of simplifying the preparation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

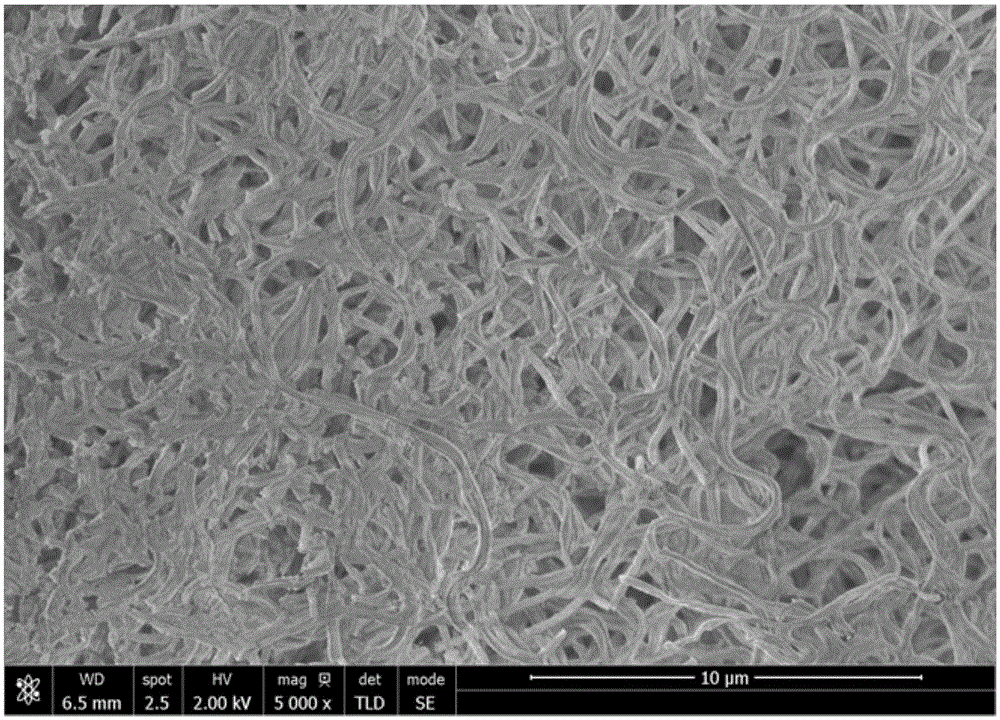

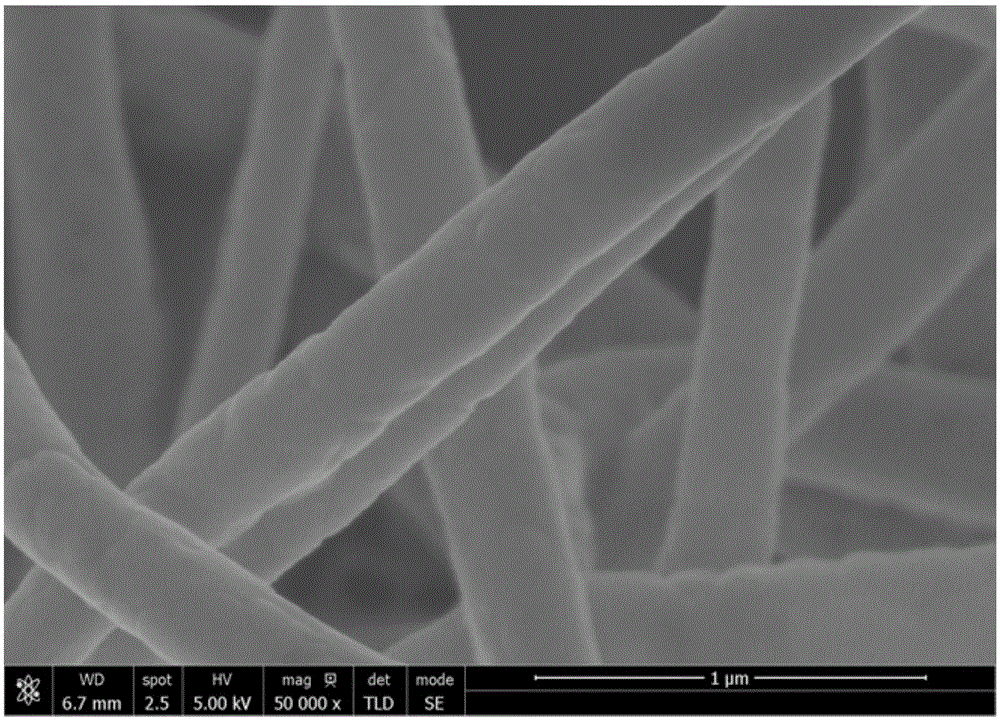

Embodiment 1

[0026] In this embodiment, a method for preparing zirconia nanofibers by electrospinning technology, the steps are as follows:

[0027] (1) Add yttrium-stabilized zirconia nanopowder in deionized water, and add polyethylene glycol (PEG), stir and mix under ultrasonic conditions and adjust the pH value of the system to 3.5 to obtain a nano-zirconia suspension; nano-zirconia The content of the yttrium-stabilized zirconia nanopowder in the suspension is 8wt%, and the amount of polyethylene glycol added is 2.5wt% of the yttrium-stabilized zirconia nanopowder;

[0028] (2) Add polyethylene oxide to the nano-zirconia suspension, stir for 24 hours to adjust the viscosity of the suspension to 1200mPa·s, and obtain an electrospinning solution;

[0029] (3) Pump the electrospinning solution into a syringe with a stainless steel needle, and perform electrospinning at a temperature of 25°C, a spinning solution ejection speed of 2.2ml / h, an applied electric field strength of 12kV, and a sp...

Embodiment 2

[0033] In this embodiment, a method for preparing zirconia nanofibers by electrospinning technology, the steps are as follows:

[0034] (1) Add magnesium-stabilized zirconia nanopowder in deionized water, and add polyethylene glycol (PEG), stir and mix under ultrasonic conditions and adjust the pH value of the system to 1.5 to obtain nano-zirconia suspension; nano-zirconia The content of the magnesium-stabilized zirconia nanopowder in the suspension is 5wt%, and the amount of polyethylene glycol added is 2.5wt% of the magnesium-stabilized zirconia nanopowder;

[0035] (2) adding dimethylamide to the nano-zirconia suspension, stirring for 24 hours to adjust the viscosity of the suspension to 1800mPa·s to obtain an electrospinning solution;

[0036] (3) Pump the electrospinning solution into a syringe with a stainless steel needle, and perform electrospinning at a temperature of 20°C, a spinning solution ejection speed of 1.0ml / h, an applied electric field strength of 30kV, and ...

Embodiment 3

[0039] In this embodiment, a method for preparing zirconia nanofibers by electrospinning technology, the steps are as follows:

[0040] (1) Add scandium-stabilized zirconia nanopowder in deionized water, and add polyethylene glycol (PEG), stir and mix under ultrasonic conditions and adjust the pH value of the system to 2.0 to obtain nano-zirconia suspension; nano-zirconia The content of the scandium-stabilized zirconia nanopowder in the suspension is 17wt%, and the amount of polyethylene glycol added is 2.5wt% of the scandium-stabilized zirconia nanopowder;

[0041] (2) adding polylactic acid to the nano-zirconia suspension, stirring for 24 hours to adjust the viscosity of the suspension to 1000mPa·s, to obtain an electrospinning solution;

[0042] (3) Pump the electrospinning solution into a syringe with a stainless steel needle, and perform electrospinning at a temperature of 30°C, a spinning solution ejection speed of 4.0ml / h, an applied electric field strength of 10kV, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com