A nanomaterial transmission electron microscope in-situ test chip, chip preparation method and application thereof

A technology of transmission electron microscopy and in-situ testing, which is applied in the analysis of materials, metal material coating process, material analysis using wave/particle radiation, etc. , to achieve the effect of being suitable for mass production, reducing chip cost and facilitating promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

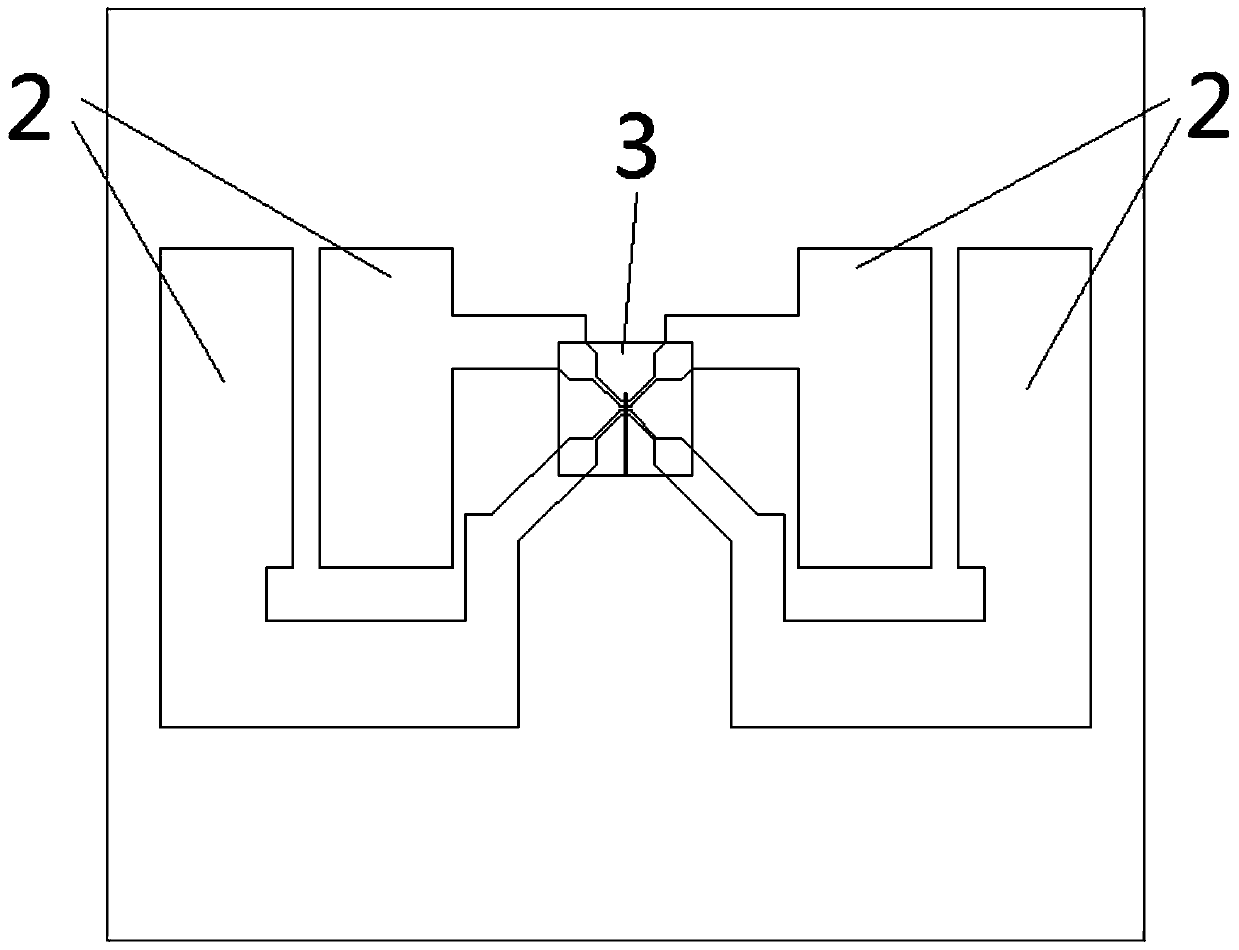

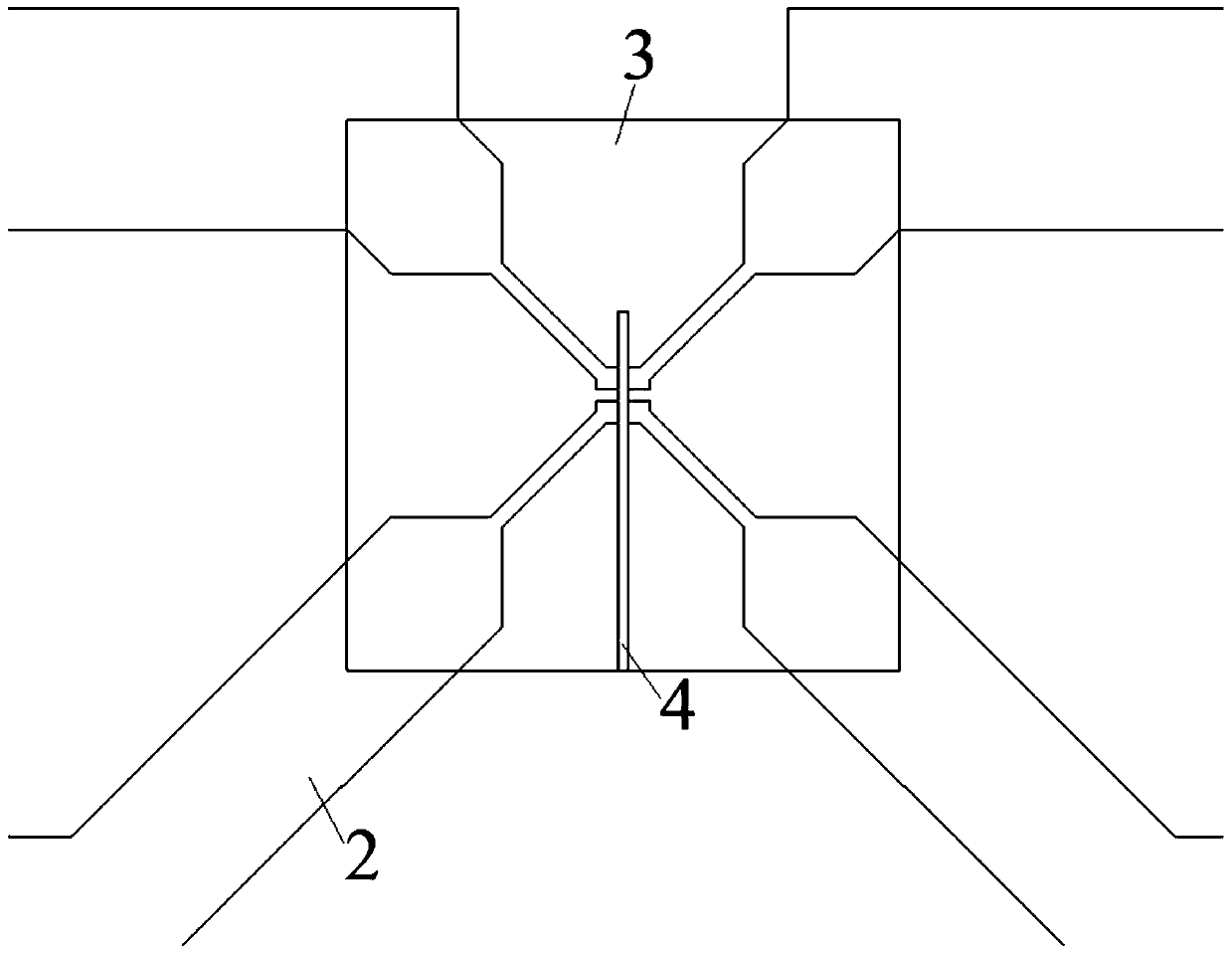

[0035] see figure 1 , figure 2 and image 3 , a nanomaterial transmission electron microscope in-situ electrical test chip of this embodiment, including a silicon substrate, an insulating layer, a thin film window 3 and an electron beam transmission region 4 . Specifically: the silicon substrate is a rectangular sheet with a thickness of 400 μm, and there are insulating layers on both sides of the silicon substrate, and the insulating layer includes a silicon dioxide layer grown on the silicon substrate and a silicon dioxide layer on the silicon dioxide layer. For the grown silicon nitride layer, the thickness of the silicon dioxide layer is 900nm, and the thickness of the silicon nitride layer is 200nm. On the insulating layer on the front side of the silicon substrate, metal thin films or devices that can apply various physical and chemical effects to the samples, or semiconductor functional thin films or devices, see figure 1 In this embodiment, a metal electrode 2 is f...

Embodiment 2

[0061] A nanomaterial transmission electron microscope in-situ electrical test chip and its preparation method in this embodiment are basically the same as in Embodiment 1, except that the thickness of the silicon substrate in this embodiment is 300 μm, and the metal electrodes are located on the film window. Some are distributed along one side of the electron beam-transmitting long groove, the length of the electron-beam transmitting long groove is 300 μm, and the width is 10 μm. The thickness of the metal electrode is 50nm, the thickness of the silicon dioxide layer in the insulating layer is 200nm, and the thickness of the silicon nitride layer is 5nm.

[0062] In this embodiment, the process of using the in-situ electrical test chip to transfer the nanowire sample in the laboratory using a micromanipulator (micromanipulator) is as follows:

[0063] (1) Under an optical microscope, a nanowire sample with a length of about 20 microns is picked up with the tip of a micromanip...

Embodiment 3

[0069] A nanomaterial transmission electron microscope in-situ electrical test chip and its preparation method in this embodiment are basically the same as in Embodiment 1, except that the thickness of the silicon substrate in this embodiment is 200 μm, and the metal electrodes are located on the film window. Parts are distributed along both sides of the electron beam-transmitting long groove, the length of the electron-beam transmitting long groove is 320 μm, and the width is 8 μm. The thickness of the metal electrode is 200nm, the thickness of the silicon dioxide layer in the insulating layer is 1000nm, and the thickness of the silicon nitride layer is 150nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com