Preparation method of anode material Fe3O4/MoS2 for lithium ion battery

A technology for lithium ion batteries and negative electrode materials, which is applied in battery electrodes, nanotechnology for materials and surface science, secondary batteries, etc., to achieve the effects of good crystallinity, novel morphology and easy control of reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

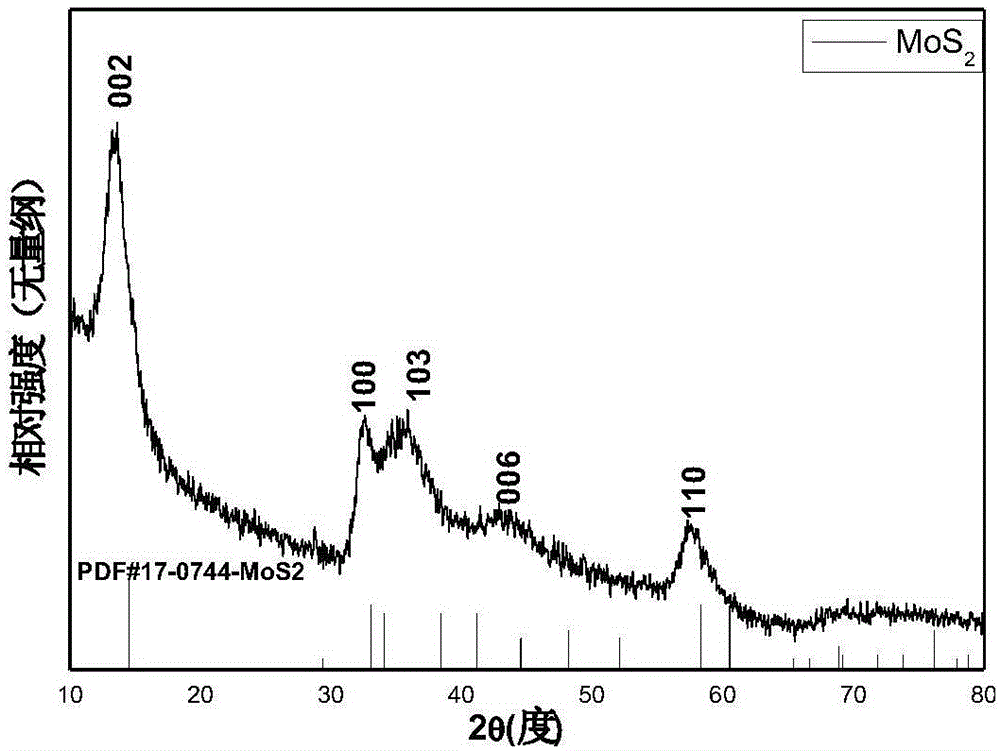

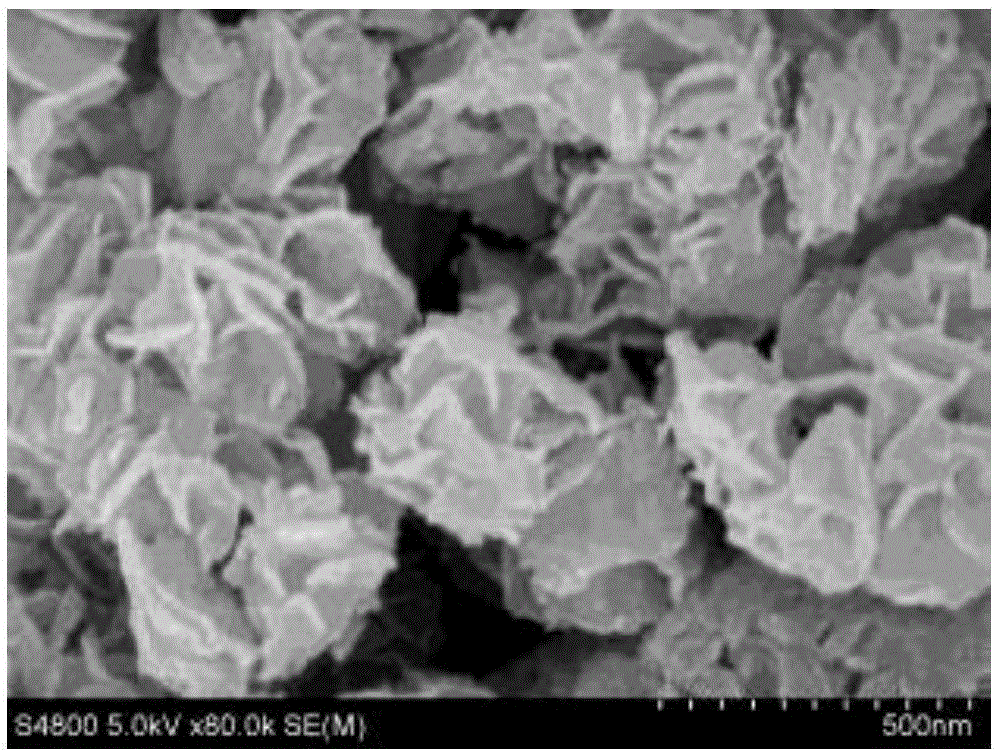

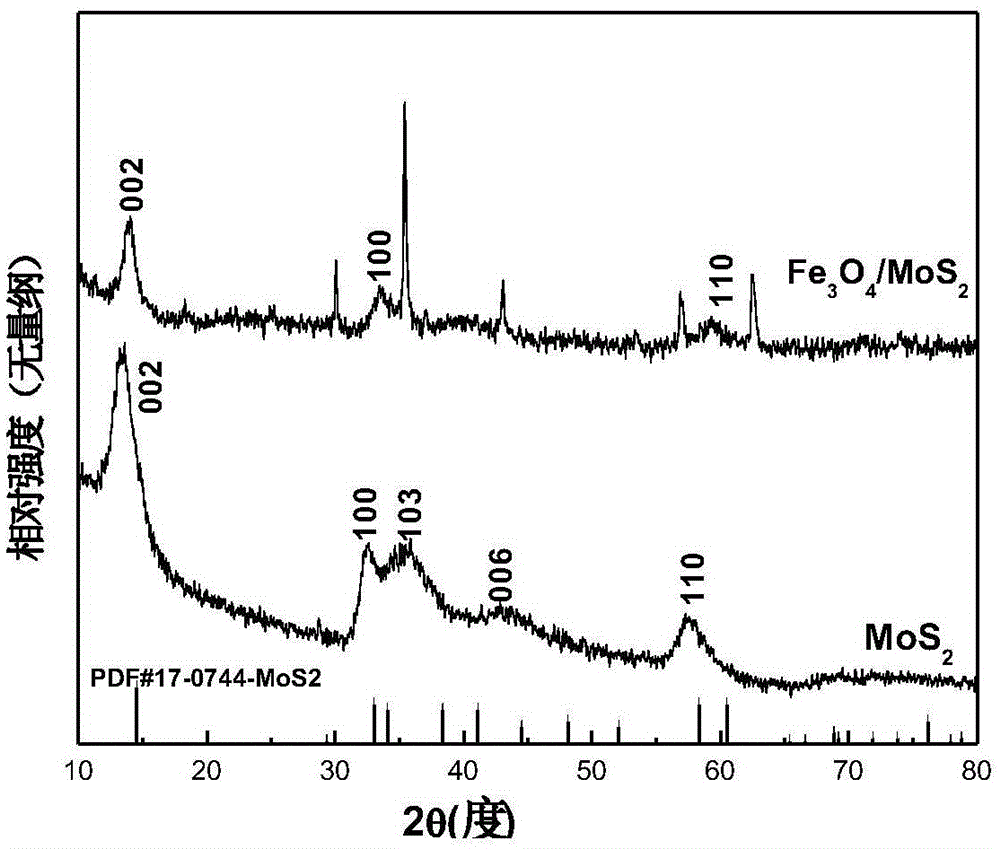

[0028] 1. Preparation of nanoflower spherical MoS 2 : Dissolve a certain amount of sodium molybdate and thiourea in distilled water at the same time, the concentrations are 0.13-0.17mol / L and 0.33-0.67mol / L respectively, during the full stirring process, add a certain amount of polyethylene glycol to make the concentration It is a solution of 0.002-0.004g / ml. After stirring, transfer the above solution to a 50ml polytetrafluoroethylene reactor, seal the reactor, and keep the temperature in an oven at 180-200°C for 16-24 hours. After the reaction was completed, after cooling down to room temperature naturally, the black precipitate was collected, washed with water and absolute ethanol several times to remove impurities, and dried at 60°C to obtain MoS 2 black powder.

[0029] 2. Preparation of MoS 2 Nanoparticle dispersion: MoS 2 The particles are dispersed into the mixture of alkali and triethanolamine with a molar ratio of 3:5 at a ratio of 5-10mg / ml, and are evenly divide...

specific Embodiment approach 2

[0036] Preparation of nanoflower cluster MoS 2 : Dissolve 0.005mol sodium molybdate and 0.02mol thiourea in 30ml distilled water, add a certain amount of polyethylene glycol with a concentration of 0.004g / ml during the process of full stirring, transfer the above solution to 50ml polytetrafluoroethylene after fully stirring In the vinyl fluoride reaction kettle, the reaction kettle was sealed, and the temperature was kept at 200° C. for 24 hours in an oven. After the reaction was completed, after cooling down to room temperature naturally, the black precipitate was collected, washed with water and absolute ethanol several times to remove impurities, and dried at 60°C to obtain MoS 2 black powder.

[0037] (a) Dissolve 0.3mol NaoH and 0.05mol triethanolamine in 100ml deionized water to prepare a mixed solution, add 5gMoS 2 , ultrasonically mixed for 30 minutes, and divided into two parts on average.

[0038] (b) Dissolve 0.0075mol ferric sulfate and 0.01mol ferrous sulfate i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com