Preparing method of manganese oxide-charcoal composite adsorbent

A composite adsorption and biochar technology, applied in chemical instruments and methods, alkali metal oxides/hydroxides, alkali metal compounds, etc., can solve the problem of low pollutant adsorption capacity, insufficient oxygen-containing groups on the surface, biochar Low content of mineral components and other problems, to achieve the effect of widening the suitable pH range, increasing the saturated adsorption capacity, and high adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

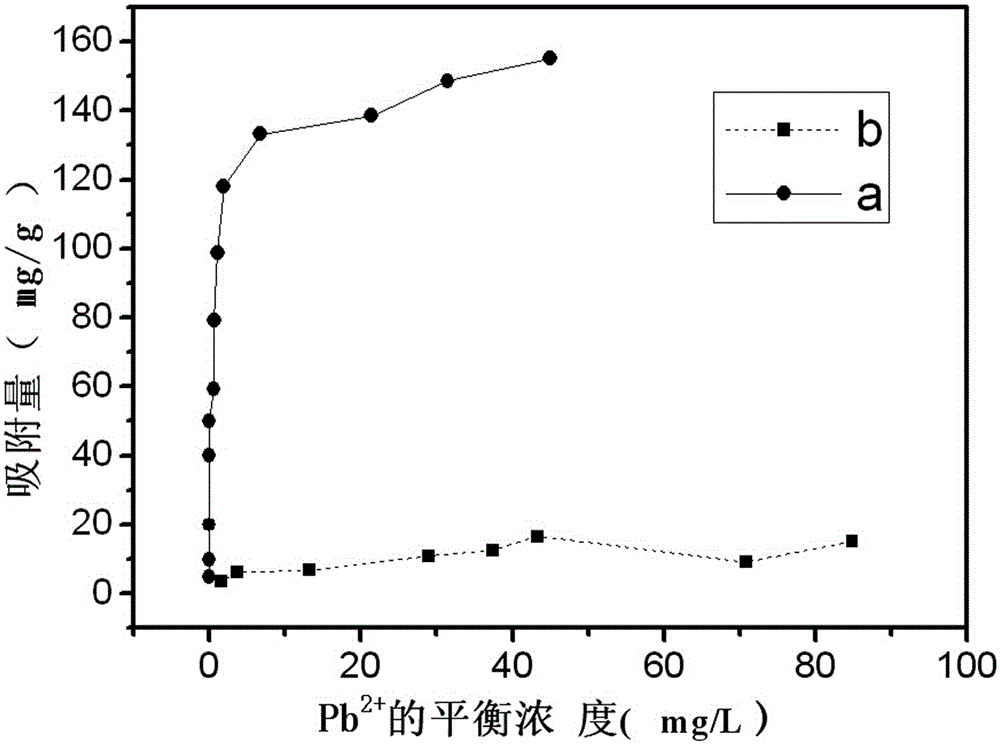

[0031] Crush the ash wood chips, pass through a sieve with a pore size of 0.425 mm (40 mesh), weigh 100 g, and determine through preliminary experiments that the volume of water required for equal-volume immersion is 0.55 L. Weigh 14.36gKMnO 4 , dissolved in 0.55L of water determined by the above experiment, so that the mass ratio of Mn element to biomass was 5.0%. Add the ash wood chips weighed above, and carry out pre-dipping treatment at room temperature (about 28°C), and keep the time for 8 hours, stirring 4 times in the middle. Then, it was dried at 105°C for 15 hours in a blast thermostat, and then transferred to a covered ceramic crucible, placed in a muffle furnace, and heated at 400°C for pyrolysis and carbonization for 4 hours. After cooling to room temperature, soak in 300 mL of 0.1 mol / L hydrochloric acid solution at room temperature and stir intermittently for 6 hours to obtain the manganese oxide-Ash sawdust biochar composite adsorbent. Replace KMnO with the sa...

Embodiment 2

[0035] According to the steps in Example 1, the biomass raw material is replaced by corn stalks, and the water volume required for equal volume impregnation is determined to be 0.5 L through preliminary experiments, and other conditions are kept unchanged, and the manganese oxide-corn stalk biochar composite can be obtained accordingly. Adsorbent and ordinary cow dung biochar adsorbent.

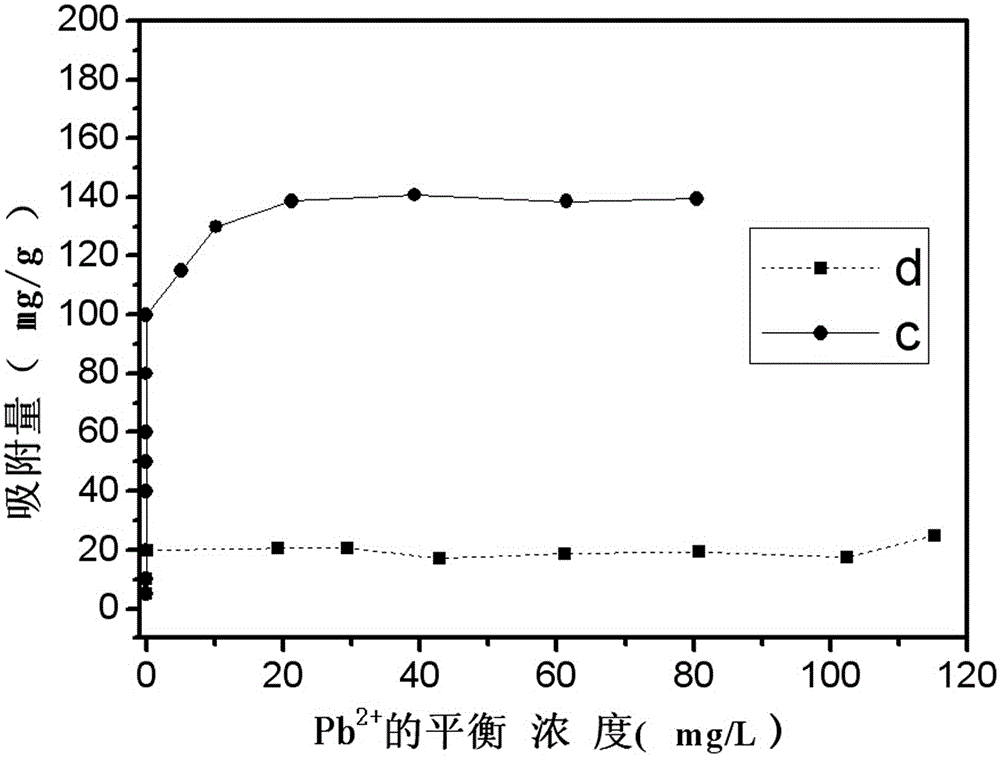

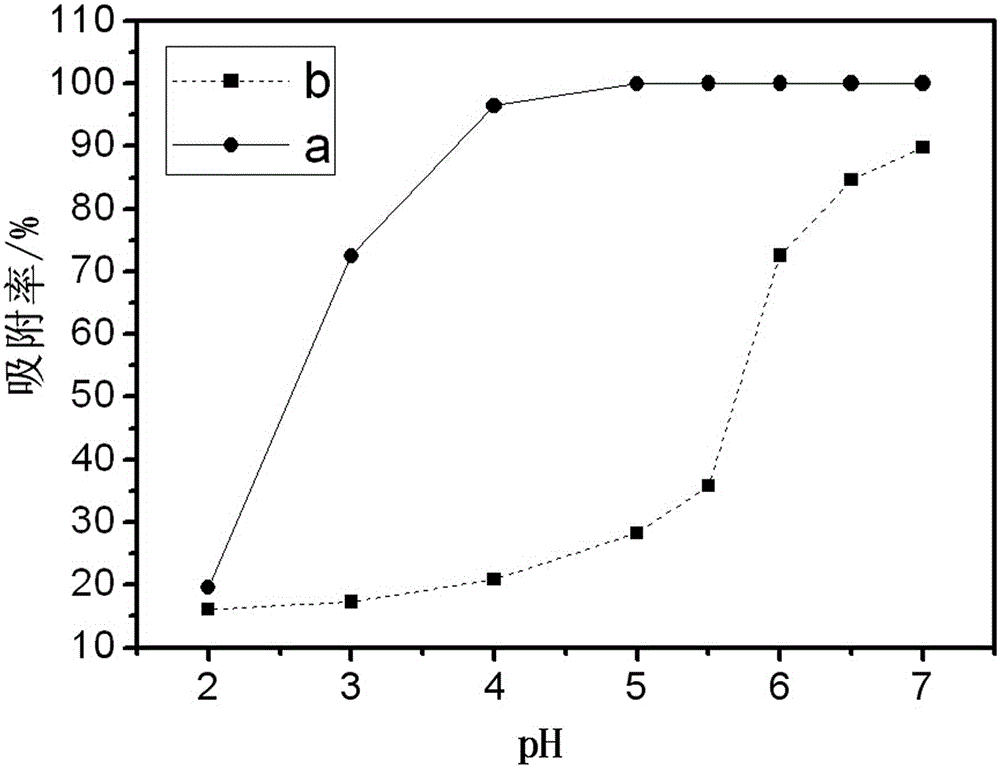

[0036] Similarly, the specific surface area of the manganese oxide-corn stalk biochar composite adsorbent measured by the method listed in Example 1 is 33.7m 2 / g, the ash content is 21.12%, the amount of oxygen-containing groups is 2.40mmoL / g, and the specific surface area of ordinary corn straw biochar adsorbent is 4.4m 2 / g, the ash content is 4.18%, and the amount of oxygen-containing groups is 1.9mmoL / g. They are to Pb 2+ The results of the adsorption isotherm and adsorption rate-pH curve are shown in the appendix respectively. figure 2 And attached Figure 4 . The results prov...

Embodiment 3

[0038] According to the steps of Example 1, keeping other conditions unchanged, after pyrolysis and carbonization, cool to room temperature, soak with 300mL of 0.1mol / L hydrochloric acid solution at 60°C and stir intermittently for 6 hours to obtain manganese oxide-water koji Willow sawdust biochar composite adsorbent. The experimental results show that the manganese oxide-Ash sawdust biochar composite material is resistant to Pb at 60℃. 2+ The saturated adsorption capacity is 100.0 mg / g, which is lower than the post-treatment adsorption capacity at room temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Saturated adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com