Synthetic method of cis-trans 1-chloro-3,3,3-trifluoropropene

A technology for the synthesis of trifluoropropene and its synthesis method, which is applied in the field of synthesis of cis-trans 1-chloro-3,3,3-trifluoropropene, which can solve the problems of HFC limitation and high greenhouse effect value, and achieve low cost and high yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

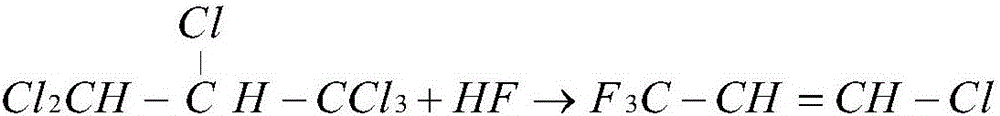

[0037] (1) Synthesis of 1,3,3,3-tetrachloropropene

[0038] 111g of cis-trans 1,3-dichloropropene is preheated to 100°C, put into a mixer and mixed with 3 times equivalent chlorine gas into a fixed bed reactor, and the fixed bed uses 100g FeCl 3 Catalysis, 210°C residence time for 1 second, and then secondary cooling to obtain 160g of crude 1,3,3,3-tetrachloropropene, and cis-trans 1,3,3,3-tetrachloropropene 145g by fractional distillation, by-product It is hexachloropropane, the yield of 1,3,3,3-tetrachloropropene is 80.65%, and the tail gas is absorbed by water to obtain hydrochloric acid.

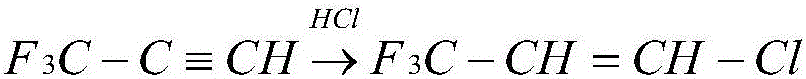

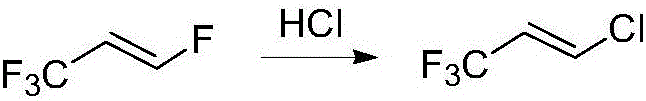

[0039] (2) Synthesis of 1-chloro-3,3,3-trifluoropropene

[0040] 89.9g of 1,3,3,3-tetrachloropropene and 100g of antimony pentafluoride were added into a 1L autoclave, and 50g of hydrogen fluoride was introduced under the seal. After the reaction, cool down to 10°C, slowly discharge excess hydrogen fluoride and hydrogen chloride into alkaline water to obtain a halide aqueous solution, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com