Method for preparing glucose-based 5-hydroxymethylfurfural from dimethyl sulphoxide and trichlorate

A technology of hydroxymethylfurfural and trichloride, which is applied in the field of biomass sugar resource utilization, can solve the problems of cumbersome solvent DMSO extraction process, lack of environmental friendliness, and high energy consumption, so as to avoid the difficulty of recycling and benefit the industry The effect of optimizing and optimizing process technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

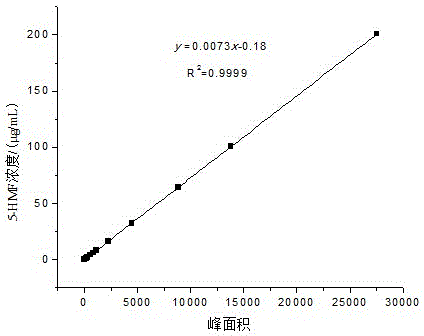

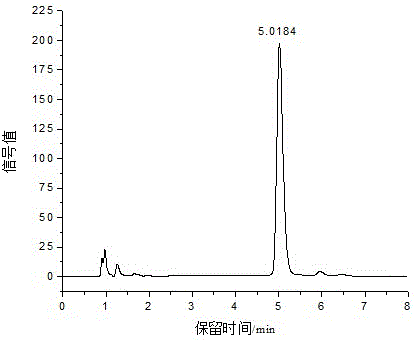

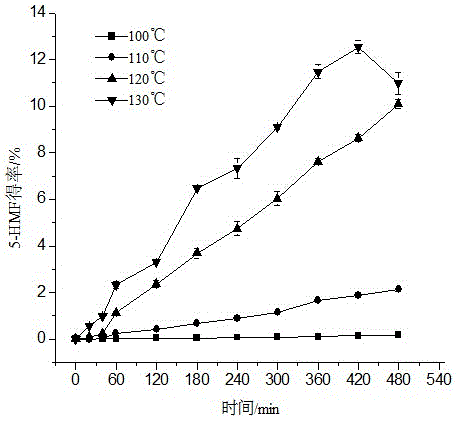

Embodiment 1

[0046] Glucose (100mg) and dimethyl sulfoxide (1mL) were added to a 5mL ampoule, ultrasonically assisted dissolution: three-frequency simultaneous ultrasonic treatment under the condition of ultrasonic frequency and power of 25kHz and 600W, 28kHz and 600W, 40kHz and 600W, respectively 15 minutes each, temperature 25-30°C, put the ultrasonic solution in a water bath at 50°C for preheating for 15 minutes, add FeCl 3 ·6H 2 O (10 mg), carry out nitrogen flushing and saturation treatment for 5 minutes, and seal with alcohol blowtorch. Under the oil bath heating conditions of 100°C, 110°C, 120°C, and 130°C, heat for 8 hours respectively, take samples every 15 minutes for the first hour, and take samples every 1 hour for the next 7 hours. Each sample was parallelized 3 times. At 130℃, the highest yield of 5-HMF was 12.54±0.27% when reacted for 420min. Distill the reacted sample at atmospheric pressure at a temperature of 105-125°C to separate 5-hydroxymethylfurfural; the remaining...

Embodiment 2

[0048] Glucose (100mg) and dimethyl sulfoxide (1mL) were added to a 5mL ampoule, ultrasonically assisted dissolution: three-frequency simultaneous ultrasonic treatment under the condition of ultrasonic frequency and power of 25kHz and 600W, 28kHz and 600W, 40kHz and 600W, respectively 15 minutes each, temperature 25-30°C, put the ultrasonic solution in a water bath at 50°C for preheating for 15 minutes, add AlCl 3 (10 mg), carry out nitrogen flushing and saturation treatment for 5 minutes, and seal with alcohol blowtorch. Under the oil bath heating conditions of 100°C, 110°C, 120°C, and 130°C, heat for 8 hours respectively, take samples every 15 minutes for the first hour, and take samples every 1 hour for the next 7 hours. Each sample was parallelized 3 times. At 120℃, the highest yield of 5-HMF was 52.86±1.10% when reacted for 240min. Distill the reacted sample at atmospheric pressure at a temperature of 105-125°C to separate 5-hydroxymethylfurfural; the remaining sample i...

Embodiment 3

[0050] Glucose (100mg) and dimethyl sulfoxide (1mL) were added to a 5mL ampoule, ultrasonically assisted dissolution: three-frequency simultaneous ultrasonic treatment under the condition of ultrasonic frequency and power of 25kHz and 600W, 28kHz and 600W, 40kHz and 600W, respectively 15 minutes each, temperature 25-30°C, put the ultrasonic solution in a water bath at 50°C for preheating for 15 minutes, add CrCl 3 ·6H 2 O (10 mg), carry out nitrogen flushing and saturation treatment for 5 minutes, and seal with alcohol blowtorch. Under the oil bath heating conditions of 100°C, 110°C, 120°C, and 130°C, heat for 8 hours respectively, take samples every 15 minutes for the first hour, and take samples every 1 hour for the next 7 hours. Each sample was parallelized 3 times. With the increase of reaction temperature and the prolongation of reaction time, the yield of 5-HMF increased continuously but did not reach the maximum value. At 130℃, the yield of 5-HMF reached 54.43±1.13% a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com