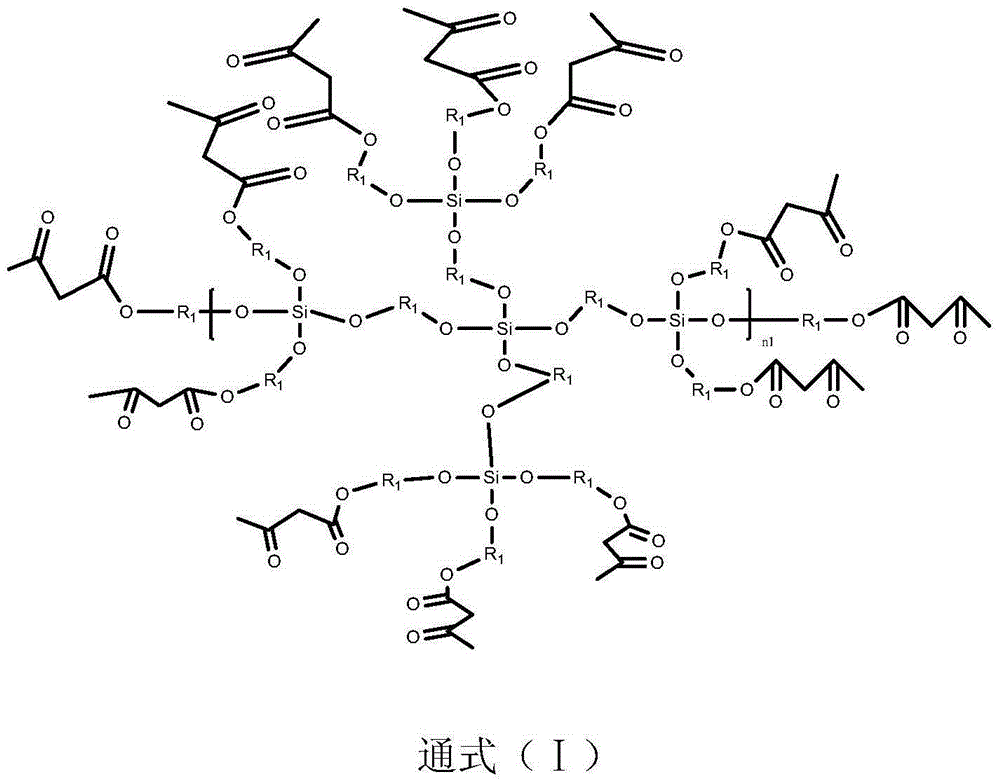

Formaldehyde removing agent and preparation method therefor

A technology of aldehyde removal agent and catalyst, which is applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve the problems of reducing the purification efficiency of formaldehyde and the inability to effectively enrich aldehyde removal substances.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

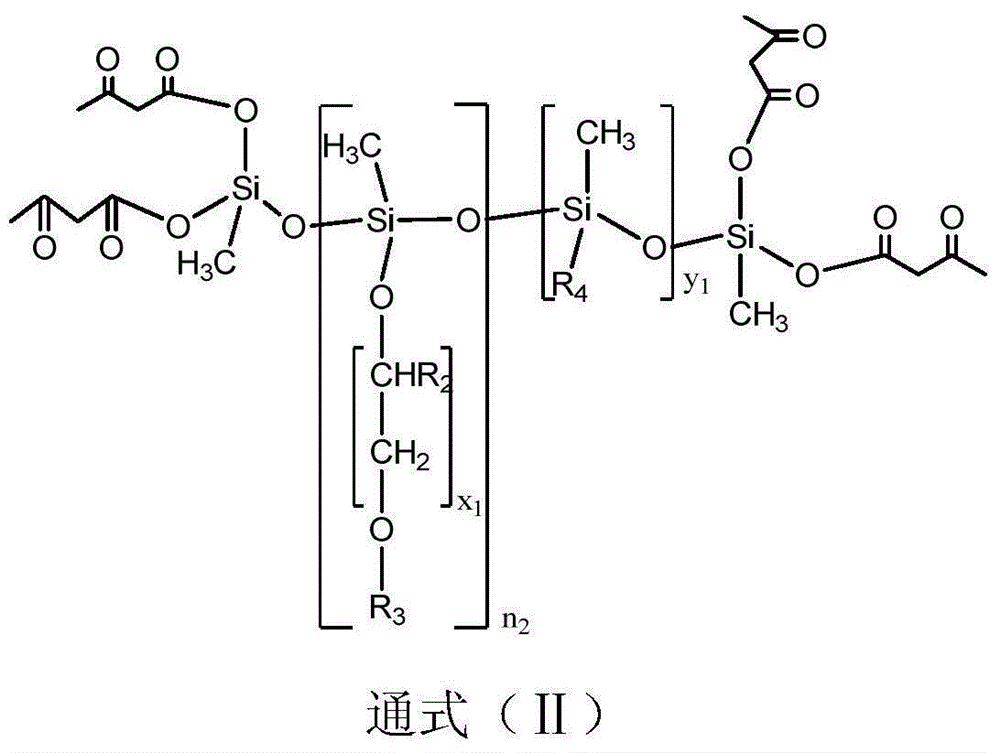

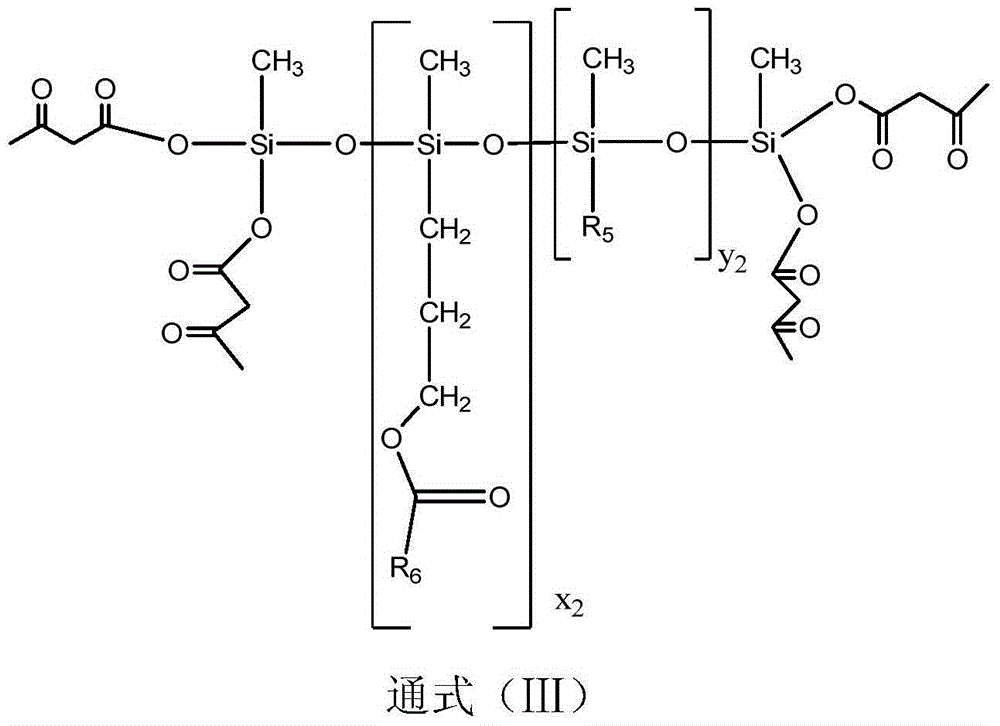

[0087] 1) Put 100.0 g of self-made branched hydroxyl-terminated polysiloxane (hydroxyl value 605, molecular weight 1112), 170.5 g of tert-butyl acetoacetate and 0.5 g of p-toluenesulfonic acid into a four-necked flask;

[0088] 2) The four-necked flask described in step 1) was ventilated with nitrogen, slowly heated, started stirring after melting, and the temperature was raised to 100-130°C for 3-4 hours, and the branched hydroxyl-terminated polysiloxane and acetoacetic acid The tert-butyl ester is transesterified, and the by-product tert-butanol will be discharged, and the discharged tert-butanol will be collected and weighed;

[0089] 3) Raise the reaction temperature to 130-170° C. to react, so that the by-product tert-butanol in step 2) has a suitable discharge rate, and take a sample for gas chromatography detection. When the tert-butyl acetoacetate content is less than 0.1%, stop the reaction. Cooling, diluting, packaging, the weight average molecular weight of the prod...

Embodiment 2

[0091] 1) Put 100.0 g of self-made branched hydroxyl-terminated polysiloxane (hydroxyl value 578, molecular weight 2134), 162.9 g of tert-butyl acetoacetate and 0.5 g of p-toluenesulfonic acid into a four-necked flask;

[0092] 2) The four-necked flask described in step 1) was ventilated with nitrogen, slowly heated, started stirring after melting, and the temperature was raised to 100-130°C for 3-4 hours, and the branched hydroxyl-terminated polysiloxane and acetoacetic acid The tert-butyl ester is transesterified, and the by-product tert-butanol will be discharged, and the discharged tert-butanol will be collected and weighed;

[0093] 3) Raise the reaction temperature to 130-170° C. to react, so that the by-product tert-butanol in step 2) has a suitable discharge rate, and take a sample for gas chromatography detection. When the tert-butyl acetoacetate content is less than 0.1%, stop the reaction. Cooling, diluting, packaging, the weight average molecular weight of the prod...

Embodiment 3

[0095] 1) Put 100.0g of self-made branched hydroxyl-terminated polysiloxane (hydroxyl value 259, molecular weight 11248), 73g of tert-butyl acetoacetate and 0.5g of p-toluenesulfonic acid into a four-necked flask;

[0096] 2) The four-necked flask described in step 1) was ventilated with nitrogen, slowly heated, started stirring after melting, and the temperature was raised to 100-130°C for 3-4 hours, and the branched hydroxyl-terminated polysiloxane and acetoacetic acid The tert-butyl ester is transesterified, and the by-product tert-butanol will be discharged, and the discharged tert-butanol will be collected and weighed;

[0097] 3) Raise the reaction temperature to 130-170° C. to react, so that the by-product tert-butanol in step 2) has a suitable discharge rate, and take a sample for gas chromatography detection. When the tert-butyl acetoacetate content is less than 0.1%, stop the reaction. Cooling, diluting, packaging, the weight average molecular weight of the product o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com