Water-based glass high-temperature baking varnish and preparation method thereof

A water-based, glass-based technology, applied in the direction of coating, etc., can solve the problems of poor wear resistance and low hardness, and achieve the effect of high water resistance and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

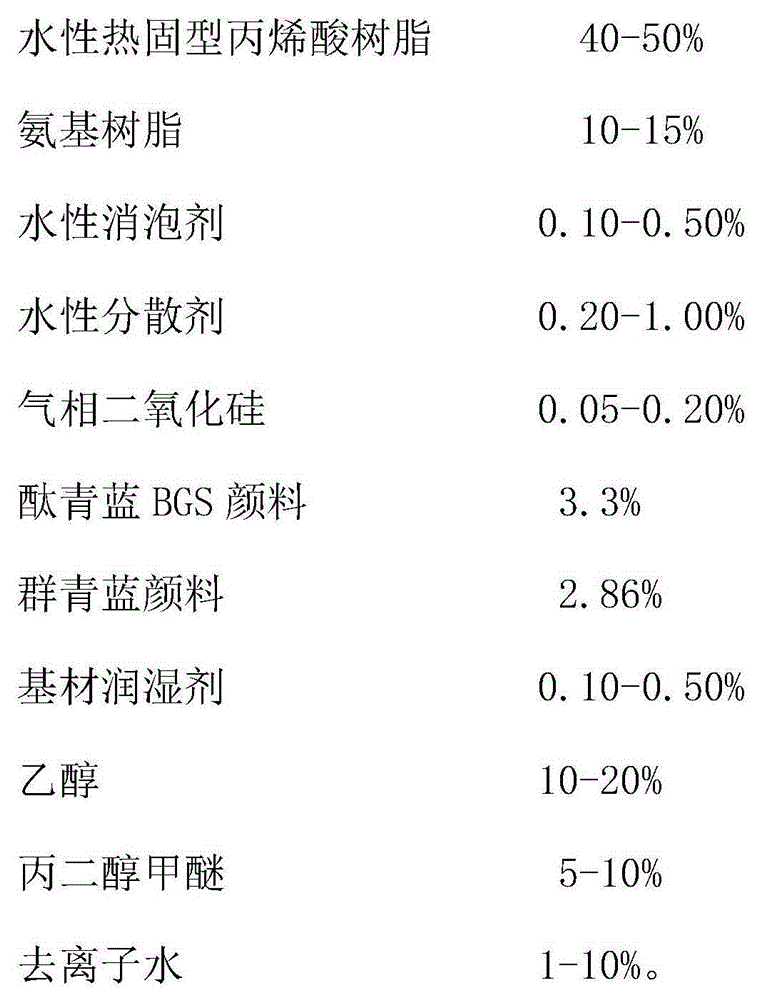

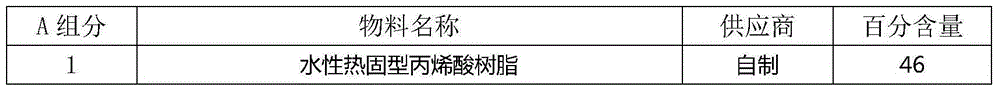

[0034] A water-based glass high-temperature baking varnish, comprising A component, B component and deionized water, including the following raw materials in weight percentage:

[0035]

[0036]

[0037] A preparation method of water-based high-temperature glass baking varnish, comprising the following steps:

[0038] (1), the water-based thermosetting acrylic resin with a weight content of 46%, the amino resin with a weight content of 14%, the water-based defoamer with a weight content of 0.10%, and the water-based dispersant with a weight content of 0.24%, were stirred and mixed at a medium speed for 10 minutes, Add 0.20% by weight of fumed silica, 3.3% by weight of phthalocyanine blue BGS pigment and 2.86% by weight of ultramarine blue pigment under stirring conditions, and stir at high speed for 20 minutes;

[0039] (2) After cooling the mixture obtained in step (1) to 25°C, grind it to a fineness≦20μm;

[0040] (3), the raw material after step (2) grinding is added...

Embodiment 2

[0043] A water-based glass high-temperature baking varnish, comprising A component, B component and deionized water, including the following raw materials in weight percentage:

[0044]

[0045] A preparation method of water-based high-temperature glass baking varnish, comprising the following steps:

[0046] (1), the water-based thermosetting acrylic resin with a weight content of 48%, the amino resin with a weight content of 14%, the water-based defoamer with a weight content of 0.10%, and the water-based dispersant with a weight content of 0.24%, were stirred and mixed at a medium speed for 10 minutes, Add 0.20% by weight of fumed silica, 3.3% by weight of phthalocyanine blue BGS pigment and 2.86% by weight of ultramarine blue pigment under stirring conditions, and stir at high speed for 20 minutes;

[0047] (2) After cooling the mixture obtained in step (1) to 25°C, grind it to a fineness≦20μm;

[0048] (3), add the substrate wetting agent of 0.3% by weight, ethanol of...

Embodiment 3

[0051] A water-based glass high-temperature baking varnish, comprising A component, B component and deionized water, including the following raw materials in weight percentage:

[0052]

[0053] A preparation method of water-based high-temperature glass baking varnish, comprising the following steps:

[0054] (1), the water-based thermosetting acrylic resin with a weight content of 50%, the amino resin with a weight content of 15%, the water-based defoamer with a weight content of 0.30%, and the water-based dispersant with a weight content of 0.34%, were stirred and mixed at a medium speed for 10 minutes, Under stirring conditions, add 0.1% by weight fumed silica, 3.3% by weight phthalocyanine blue BGS pigment and 2.86% by weight ultramarine blue pigment, and stir at high speed for 20 minutes;

[0055] (2) After cooling the mixture obtained in step (1) to 25°C, grind it to a fineness≦20μm;

[0056] (3), add the substrate wetting agent of 0.1% by weight, ethanol of 12% by w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com