Sealing compound for zinc-manganese battery and preparation method of sealing compound

A zinc-manganese battery and sealing glue technology, applied in dry batteries, battery pack components, circuits, etc., can solve the problems of poor sealing, easy aging and service life, and achieve long service life, easy coating, and good adhesion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] A method for preparing a sealant for a zinc-manganese battery of the present invention includes the following steps: 1) heating 40 parts by weight of asphalt at 150°C for 2 hours, adding 20 parts by weight of hydrogenated saturated polybutene, 30 parts by weight of modified epoxy resin, 20 parts by weight of nonylphenol polyoxyethylene ether, 1 part by weight of nano-titanium dioxide and 1 part by weight of nano-flaky aluminum powder, and stir evenly to obtain a crude product; 2) to be obtained in step 1) When the temperature of the crude product is cooled to 80°C, add 20 parts by weight of No. 120 solvent gasoline, 10 parts by weight of aromatic hydrocarbon oil and 20 parts by weight of simethicone oil, stir evenly, filter and pack to obtain the product.

Embodiment 2

[0014] A method for preparing a sealant for a zinc-manganese battery of the present invention includes the following steps: 1) heating 45 parts by weight of asphalt at 180°C for 3 hours, and adding 25 parts by weight of hydrogenated saturated polybutene, 35 parts by weight of modified epoxy resin, 25 parts by weight of nonylphenol polyoxyethylene ether, 3 parts by weight of nano-titanium dioxide and 3 parts by weight of nano-flaky aluminum powder, and stir evenly to obtain a crude product; 2) to be obtained in step 1) When the temperature of the crude product is cooled to 100°C, add 25 parts by weight of No. 120 solvent gasoline, 15 parts by weight of aromatic oil and 15 parts by weight of simethicone oil, stir evenly, filter, and pack to obtain the product.

Embodiment 3

[0016] A method for preparing a sealant for a zinc-manganese battery of the present invention includes the following steps: 1) heating 50 parts by weight of asphalt at 200°C for 5 hours, adding 30 parts by weight of hydrogenated saturated polybutene, 40 parts by weight of modified epoxy resin, 30 parts by weight of nonylphenol polyoxyethylene ether, 5 parts by weight of nano-titanium dioxide and 5 parts by weight of nano-flaky aluminum powder, and stir evenly to obtain a crude product; 2) to be obtained in step 1) When the temperature of the crude product is cooled to 120°C, add 30 parts by weight of No. 120 solvent gasoline, 20 parts by weight of aromatic hydrocarbon oil and 20 parts by weight of simethicone oil, stir evenly, filter and pack to obtain the product.

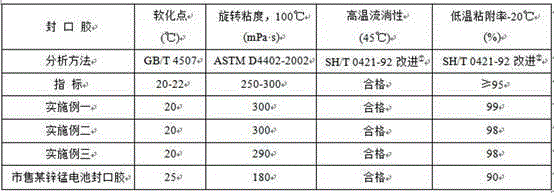

[0017] Three kinds of sealants for zinc-manganese batteries obtained in Examples 1 to 3 and a commercially available sealant for zinc-manganese batteries were tested for their performance with reference to the rele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Rotational viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com