Application of Candida tropicalis in producing dodecanedioic acid from unsaturated oil

A technology of Candida tropicalis and dodecanediacid, applied in the field of bioengineering, can solve problems such as increased production cost of dibasic acid, and achieve the effects of simple and easy process, low cost of raw materials and reduction of production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

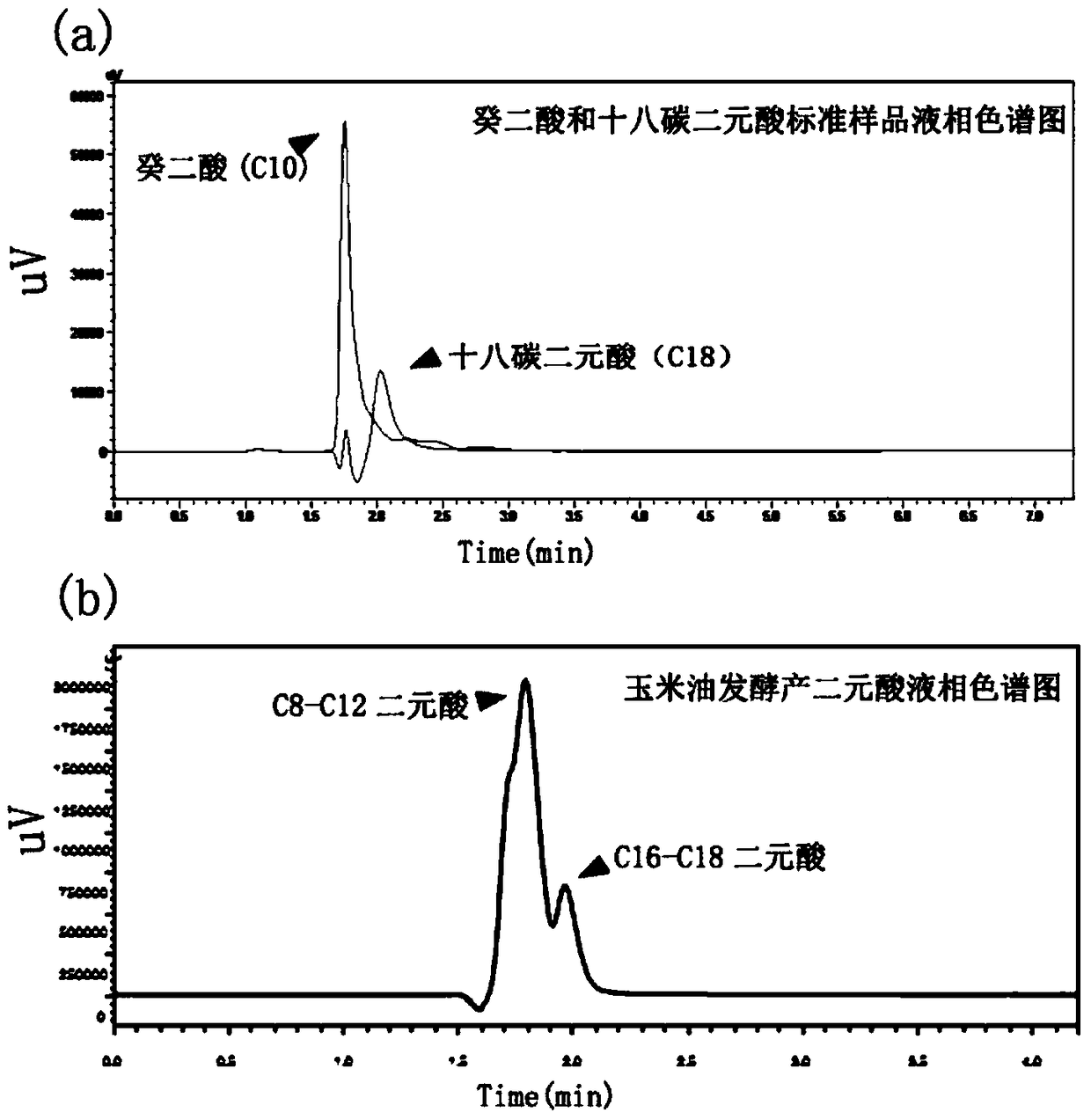

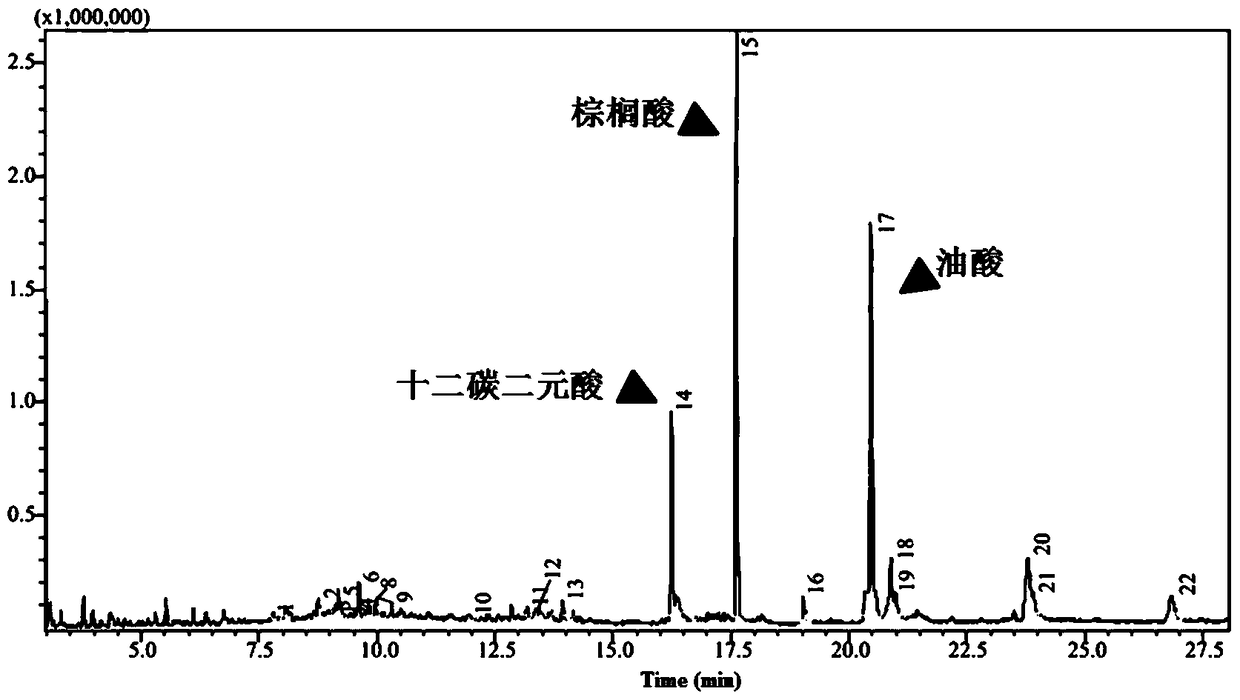

[0034] Example 1, Catalyzing the Screening of Unsaturated Fatty Acid Unsaturated Bond Breaking Bacteria in Catalytic Oil Components

[0035] Candida sake CICC 33015, Candida lipolytica CICC 1457, Candida tropicalis CICC 1798 purchased from China Industrial Microorganism Culture Collection Management Center and dibasic acid high-yielding yeast Candida preserved in the Institute of Enzyme Engineering, Qilu University of Technology After activation, tropicalis IEE001 was inoculated into the screening medium, in which the medium components were yeast extract powder 10g / L, peptone 20g / L, glucose 20g / L, peanut oil 50ml / L, tap water configuration, natural pH, 115 °C for 30 minutes. After the fermentation, the fermented liquid was adjusted to pH 12, then heated to 90°C, and treated for 30 minutes. Centrifuge at 7000 rpm for 5 minutes while hot to remove bacteria. Adjust the pH value of the supernatant in the above steps to about 2.95, heat again to 90°C and keep for 30min; slowly co...

Embodiment 2

[0037] Embodiment 2, fermenting corn oil in 500mL shake flask produces dodecanedioic acid

[0038] The application of Candida tropicalis in the production of dodecanedibasic acid by using unsaturated oil, the steps are as follows:

[0039](1) Inoculate 5 mL of Candida tropicalis seed liquid into 100 mL of fermentation medium, and add glucose solution every 12 hours at a temperature of 30°C and a rotational speed of 210 r / min, so that the glucose concentration is 6.2%, and adjust once at the same time pH control the pH of the fermentation broth to 6.0, and ferment for 24 hours; then, add corn oil every 12 hours to make the oil mass concentration 10%, control the pH of the fermentation broth to 7.5, and ferment for 120 hours to obtain the fermentation broth;

[0040] Fermentation medium in described step (1), component is as follows:

[0041] Glucose 50g / L, (NH 4 ) 2 SO 4 1g / L, corn syrup 1g / L, yeast extract 2g / L, VB 1 0.1g / L, NaCl 2g / L, KH 2 PO 4 6g / L, Na 2 HPO 4 12...

Embodiment 3

[0048] Embodiment 3, fermenting corn oil in 5L fermentation tank produces dodecane dibasic acid

[0049] The application of Candida tropicalis in the production of dodecanedibasic acid by using unsaturated oil, the steps are as follows:

[0050] (1) Inoculate 300mL of Candida tropicalis seed liquid into 3L fermentation medium, and add glucose solution under the conditions of temperature 30°C, ventilation ratio 1:0.7vvm, and tank pressure 0.08Mpa, so that the glucose concentration is 6.2% , control the pH of the fermentation broth to 6.0, and ferment for 24 hours; then, add unsaturated oil to make the oil mass concentration 10%, control the pH of the fermentation broth to 7.5, and ferment for 120 hours to obtain the fermentation broth;

[0051] Fermentation medium in described step (1), component is as follows:

[0052] Glucose 40g / L, (NH 4 ) 2 SO 4 1g / L, corn syrup 1g / L, yeast extract 2g / L, VB 1 0.1g / L, NaCl 2g / L, KH 2 PO 4 4g / L, Na 2 HPO 4 12H 2 O 10.08g / L, urea ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com