Green multi-metal cooperation stabilization agent for fly ash and application method for green multi-metal cooperation stabilization agent

A composite stabilizer and fly ash technology, which is applied in the restoration of polluted soil and the removal of solid waste, can solve the problems of difficulty in fixing multiple metals at the same time with a single agent, reducing the dosage of chemicals, and adding a large amount of chelating agents. Achieve significant environmental and social benefits, reduce environmental costs and costs, and reduce processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0028] The incineration fly ash used in this embodiment is the domestic waste incineration fly ash of a waste incineration plant in Southwest my country. The components of fly ash were determined according to USEPA3050, and the results are shown in Table 1.

[0029] Table 1 The main components of fly ash

[0030] Composition

Mass percentage (%)

SiO 2

49.51

Fe 2 o 3

9.66

Al 2 o 3

7.52

CaO

13.74

SO 3

9.2

Na 2 o

5.11

TiO 2

5.26

[0031] It can be seen from Table 1 that the main components of fly ash are Si, Fe, Al, Ca, S, Na, Ti.

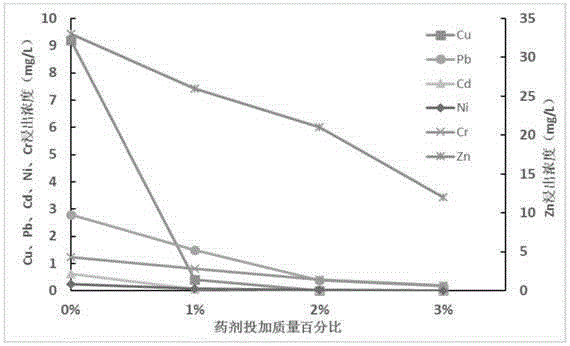

[0032] The main heavy metal content of fly ash was digested and determined by ASTMD6357-00a digestion method, and the leaching toxicity was determined by "Solid waste leaching toxicity leaching method acetic acid buffer solution method" (HJ / T300-2007). The results are shown in Table 2.

[0033] Table 2 Content and leaching concentration of ...

Embodiment example 2

[0042] The incineration fly ash used in this example is the domestic waste incineration fly ash of a waste incineration plant in central China. The fly ash group was determined according to USEPA3050, and the results are shown in Table 4.

[0043] Table 4 Main components of fly ash

[0044] Composition

Mass percentage (%)

SiO 2

54.03

Fe 2 o 3

8.62

Al 2 o 3

5.11

CaO

11.24

Na 2 o

9.77

K 2 o

4.38

MgO

6.85

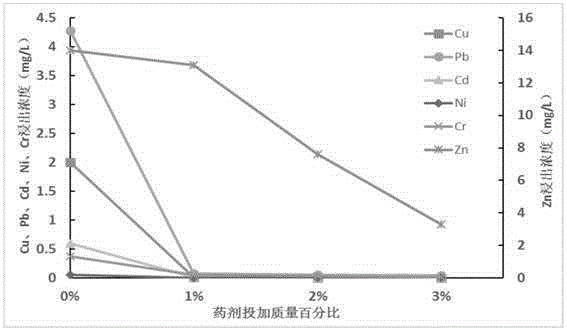

[0045] The main heavy metal content of fly ash was digested and determined by ASTM D6357-00a digestion method, and the leaching toxicity was determined by "Solid waste leaching toxicity leaching method acetic acid buffer solution method" (HJ / T300-2007). The results are shown in Table 5.

[0046] Table 5 Content and leaching concentration of heavy metals in fly ash

[0047]

[0048] It can be seen from Table 5 that Cd and Pb are excessive pollutants in fly ash, a...

Embodiment example 3

[0055] The incineration fly ash used in this embodiment is the domestic waste incineration fly ash of a waste incineration plant in South China. The fly ash group was determined according to USEPA3050, and the results are shown in Table 7.

[0056] Table 7 Main components of fly ash

[0057] Composition

Mass percentage (%)

SiO 2

42.58

Fe 2 o 3

8.96

al 2 o 3

9.88

CaO

18.23

MgO

4.20

Na 2 o

6.00

K 2 o

10.15

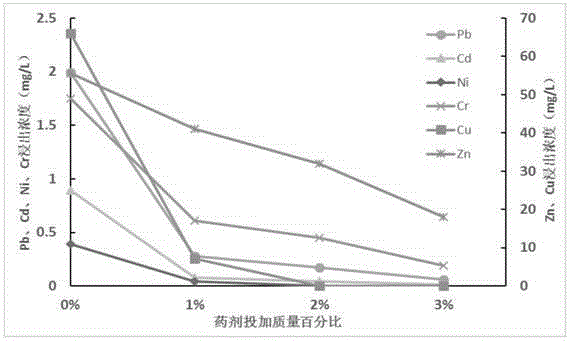

[0058] The main heavy metal content of fly ash was digested and determined by ASTM D6357-00a digestion method, and the leaching toxicity was determined by "Solid Waste Leaching Toxicity Leaching Method Acetic Acid Buffer Solution Method" (HJ / T300-2007). The results are shown in Table 8.

[0059] Table 8 Content and leaching concentration of heavy metals in fly ash

[0060]

[0061]

[0062] It can be seen from Table 8 that Cd, Pb, Cu, and Cr are excessive p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com