A red low-angle-dependent zinc sulfide structural color pigment and its preparation method

A zinc sulfide, low-angle technology, applied in the direction of zinc sulfide, etc., can solve the problems of reducing structural color dependence, difficulty in wide application, and impact on film quality, achieving no angle dependence, simple and easy process operation, and solution easy to fade effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

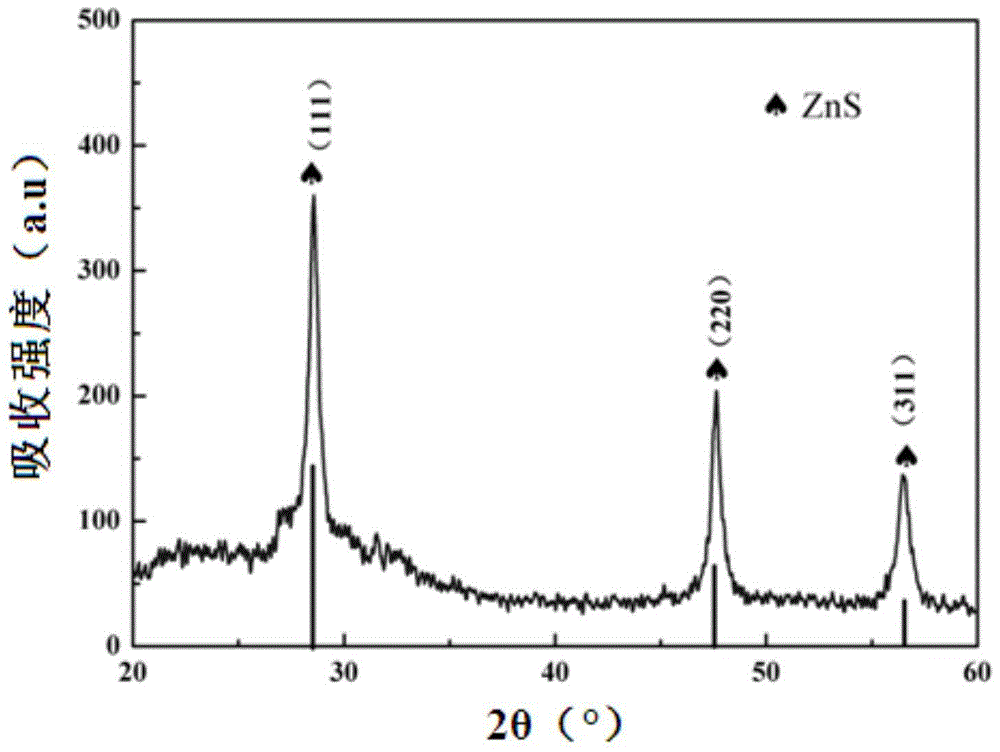

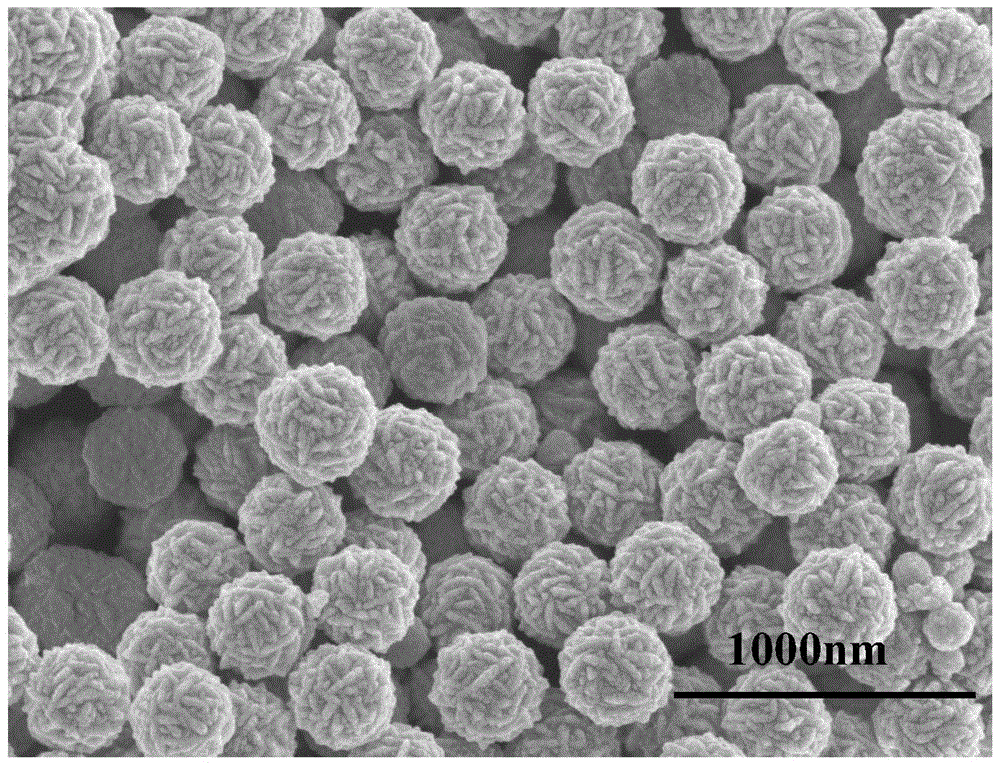

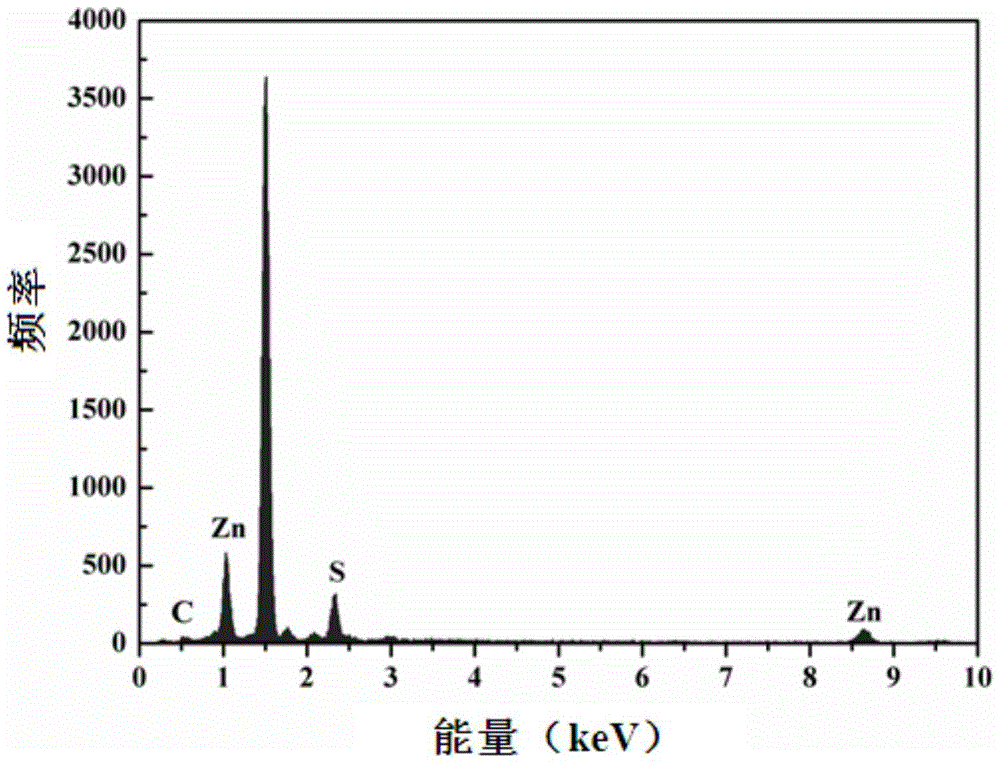

[0027] The present invention is achieved through the following technical solutions:

[0028] A preparation method of a low-angle-dependent red zinc sulfide structural color pigment, comprising the following steps:

[0029] 1) Weigh Zn(NO 3 ) 2 ·6H 2 O and some grams of polyvinylpyrrolidone (PVP), add in the beaker, according to the ratio of 0.03g PVP: 100mL deionized water, the total amount of water is 100mL magnetic stirring is fully dissolved and evenly mixed, stirred for 30min to obtain a uniform solution;

[0030] 2) Accurately weigh 0.3 g of thioacetamide, add 50 mL of deionized water and ultrasonically mix for 10-20 minutes to obtain an aqueous solution of thioacetamide;

[0031] 3) Stir the above two homogeneous solutions of 1) and 2) respectively, add them into the same beaker, and react in a water bath at 80°C for 6 hours under magnetic stirring to obtain an emulsion containing zinc sulfide microspheres, and then wash with water , alcohol washing three times and u...

Embodiment 2

[0035] 1) Weigh Zn(NO 3 ) 2 ·6H 2 O and some grams of polyvinylpyrrolidone (PVP), add in the beaker, according to the ratio of 0.02g PVP: 100mL deionized water, the total amount of water is 100mL magnetic stirring is fully dissolved and evenly mixed, stirred for 30min to obtain a uniform solution;

[0036] 2) Accurately weigh 0.3 g of thioacetamide, add 50 mL of deionized water and ultrasonically mix for 10-20 minutes to obtain an aqueous solution of thioacetamide;

[0037]3) Stir the above two homogeneous solutions of 1) and 2) respectively, add them into the same beaker, and react in a water bath at 70° C. for 8 hours under magnetic stirring to obtain an emulsion containing zinc sulfide microspheres. After washing with water and washing with alcohol for three times, ultrasonic dispersion is carried out to obtain an ethanol solution of monodisperse zinc sulfide microspheres;

[0038] 4) Dry the ethanol solution of monodisperse zinc sulfide microspheres prepared in step 3) ...

Embodiment 3

[0040] 1) Weigh Zn(NO 3 ) 2 ·6H 2 O and some grams of polyvinylpyrrolidone (PVP), add in the beaker, according to the ratio of 0.03g PVP: 100mL deionized water, the total amount of water is 100mL magnetic stirring is fully dissolved and evenly mixed, stirred for 30min to obtain a uniform solution;

[0041] 2) Accurately weigh 0.4 g of thioacetamide, add 50 mL of deionized water and ultrasonically mix for 10-20 minutes to obtain an aqueous solution of thioacetamide;

[0042] 3) Stir the above two homogeneous solutions of 1) and 2) respectively, add them into the same beaker, and react in a water bath at 85° C. for 5 hours under magnetic stirring to obtain an emulsion containing zinc sulfide microspheres. After washing with water and washing with alcohol for three times, ultrasonic dispersion is carried out to obtain an ethanol solution of monodisperse zinc sulfide microspheres;

[0043] 4) Dry the ethanol solution of monodisperse zinc sulfide microspheres prepared in step 3)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com