Rubber material for weather-resistant and aging-resistant plate type rubber support

A rubber bearing and rubber material technology, which is applied in the field of rubber materials for weather-resistant and aging-resistant plate rubber bearings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

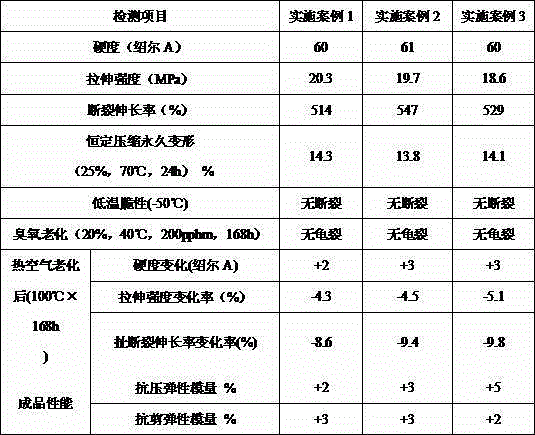

Examples

Embodiment 1

[0040] The first step is to prepare the rubber

[0041] Put 20 parts by weight of natural rubber into the internal mixer for plastic training for 1 minute, then put 80 parts by weight of rubber-type chlorinated polyethylene into the internal mixer and mix for 3 minutes, then add 4 parts by weight of zinc oxide, 2 parts by weight of hard Fatty acid, 8 parts by weight magnesium oxide, 1.0 parts by weight antioxidant a, 1.5 parts by weight antioxidant b and 1.0 parts by weight paraffin were mixed for 2 minutes, then added 50 parts by weight of modified nano-attapulgite and mixed for 1 minute, and then Add 40 parts by weight of carbon black N330 and 10 parts by weight of plasticizer dioctyl phthalate and knead for 3 minutes, finally add 2 parts by weight of organic peroxide vulcanizing agent dicumyl peroxide, 0.6 parts by weight of sulfur, 1.2 Parts by weight of accelerator CZ and 0.8 parts by weight of accelerator DM were mixed for 1 minute, the temperature should not exceed 110°...

Embodiment 2

[0045] The first step is to prepare the rubber

[0046] Put 25 parts by weight of natural rubber into the internal mixer for 1.5 minutes of plastic training, then put 75 parts by weight of rubber-type chlorinated polyethylene into the internal mixer and mix for 2.5 minutes, then add 5 parts by weight of zinc chloride, 2.0 parts by weight of hard Fatty acid, 7.5 parts by weight magnesium oxide, 1.5 parts by weight antioxidant a, 1.5 parts by weight antioxidant b and 1.0 parts by weight paraffin were mixed for 2 minutes, then added 40 parts by weight of modified nano-attapulgite and mixed for 1 minute, then added 30 parts by weight of carbon black N330 and 25 parts by weight of carbon black N550, 8 parts by weight of plasticizer dioctyl adipate were mixed for 3 minutes, and finally added 3 parts by weight of organic peroxide vulcanizing agent di-tert-butylperoxyhexane , 0.5 parts by weight of sulfur, 2 parts by weight of auxiliary crosslinking agent TAIC and 0.6 parts by weight ...

Embodiment 3

[0050] The first step is to prepare the rubber

[0051] Put 30 parts by weight of natural rubber into the banbury mixer for 1.5 minutes of plastic training, then put 70 parts by weight of rubber-type chlorinated polyethylene into the banbury mixer and mix for 2.5 minutes, then add 4 parts by weight of zinc chloride, 3 parts by weight of hard Fatty acid, 7 parts by weight of magnesium oxide, 2 parts by weight of antioxidant a, 1 part by weight of antioxidant b and 1.5 parts by weight of paraffin were mixed for 2 minutes, then 45 parts by weight of modified nano-attapulgite were added and mixed for 1 minute, and then added 30 parts by weight of carbon black N330 and 20 parts by weight of carbon black N550 and 12 parts by weight of plasticizer dioctyl sebacate were mixed for 3 minutes, and finally added 1.5 parts by weight of dicumyl peroxide, 1.0 parts by weight of di-tert-butyl Organic peroxide vulcanizing agent composed of hexane peroxide and 1.0 parts by weight of benzoyl per...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com