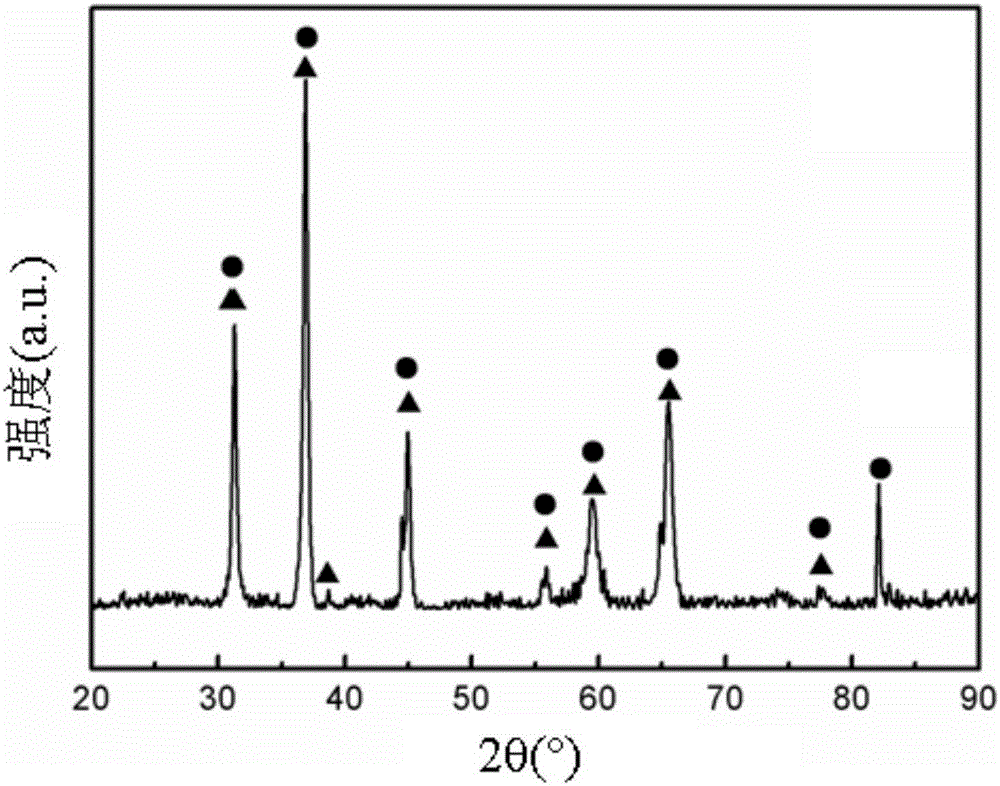

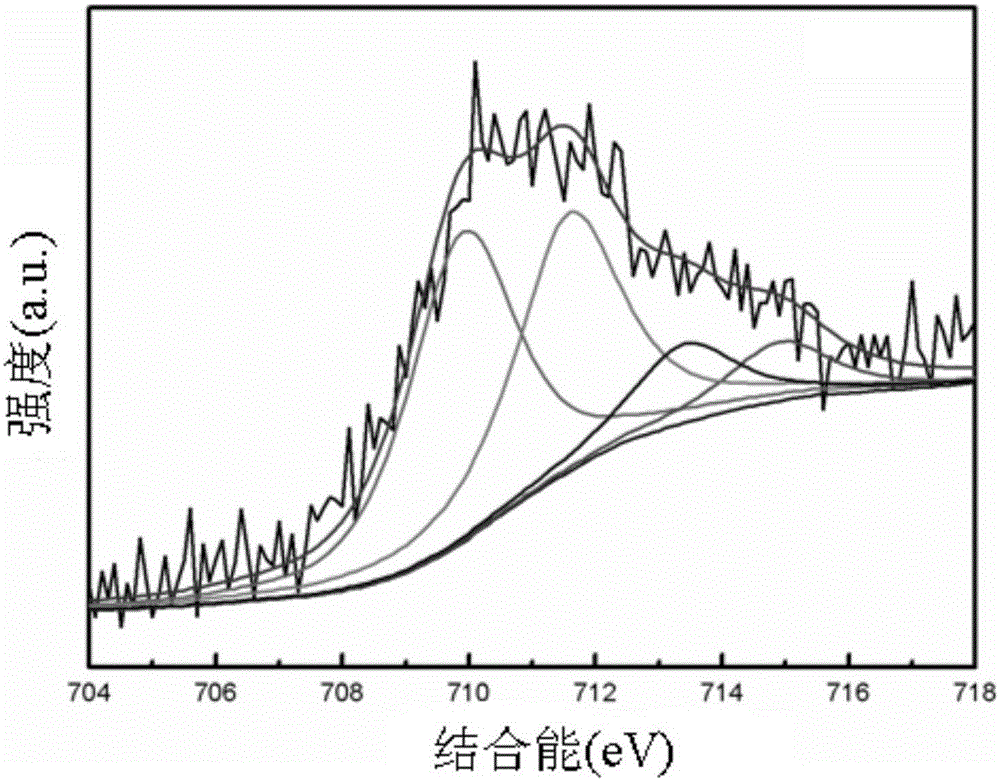

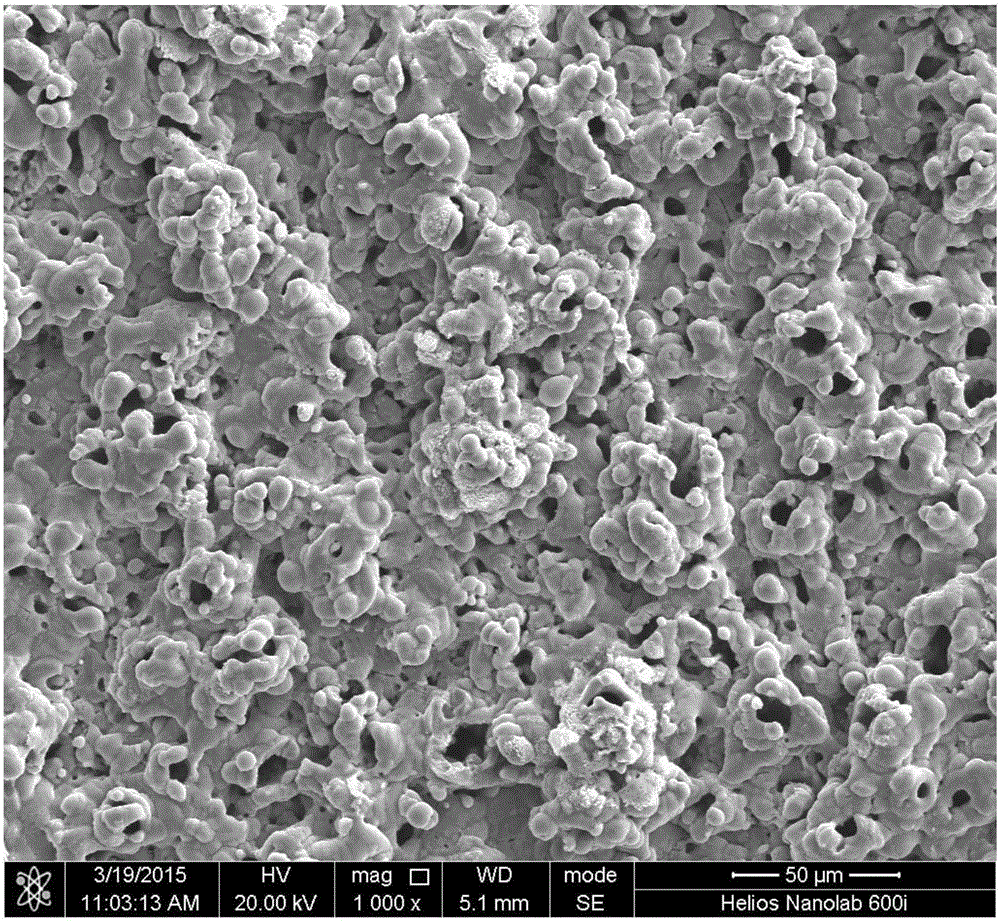

Preparation method and application of efficient Fe3O4/FeAlO4 composite coating Fenton-like catalyst

A composite membrane layer, feal2o4 technology, applied in the direction of physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve problems such as poor mechanical properties, difficult separation and recycling of catalysts, etc. , to achieve excellent stability, good application prospects, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0027] Specific implementation mode one: the present implementation mode is a method for preparing high-efficiency Fe 3 O 4 / FeAl 2 O 4 The method of composite membrane layer class Fenton catalyst is to be finished according to the following steps:

[0028] 1. Carbon steel polishing treatment: First, use 500 mesh water abrasive paper, 1000 mesh water abrasive paper, 1500 mesh water abrasive paper, 2000 mesh water abrasive paper and 2500 mesh water abrasive paper to polish the surface of carbon steel until the surface of carbon steel is a mirror surface; Then use deionized water to rinse the surface of the carbon steel for 3 to 5 times, then use absolute ethanol to rinse the surface of the carbon steel for 3 to 5 times, and finally use a hair dryer to dry it to obtain a bright carbon steel;

[0029] Two, the bright carbon steel obtained in step 1 is placed in the electrolytic solution in the stainless steel electrolytic cell, the bright carbon steel is connected with the pos...

specific Embodiment approach 2

[0040] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the main film-forming agent is sodium aluminate. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0041] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the additive is sodium hypophosphite monohydrate. Other steps are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com