Method for preparing metal-oxide compound nano catalyst by molecular layer deposition

A technology of molecular layer deposition and nano-catalyst, applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, chemical instrument and method, etc., can solve the uniformity and interface structure of unsuitable oxide nanoparticles , reduced catalytic performance, and porous membranes occupying the active sites of metal particles, etc., to achieve excellent catalytic performance, simple and easy-to-control method, and good product preparation uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

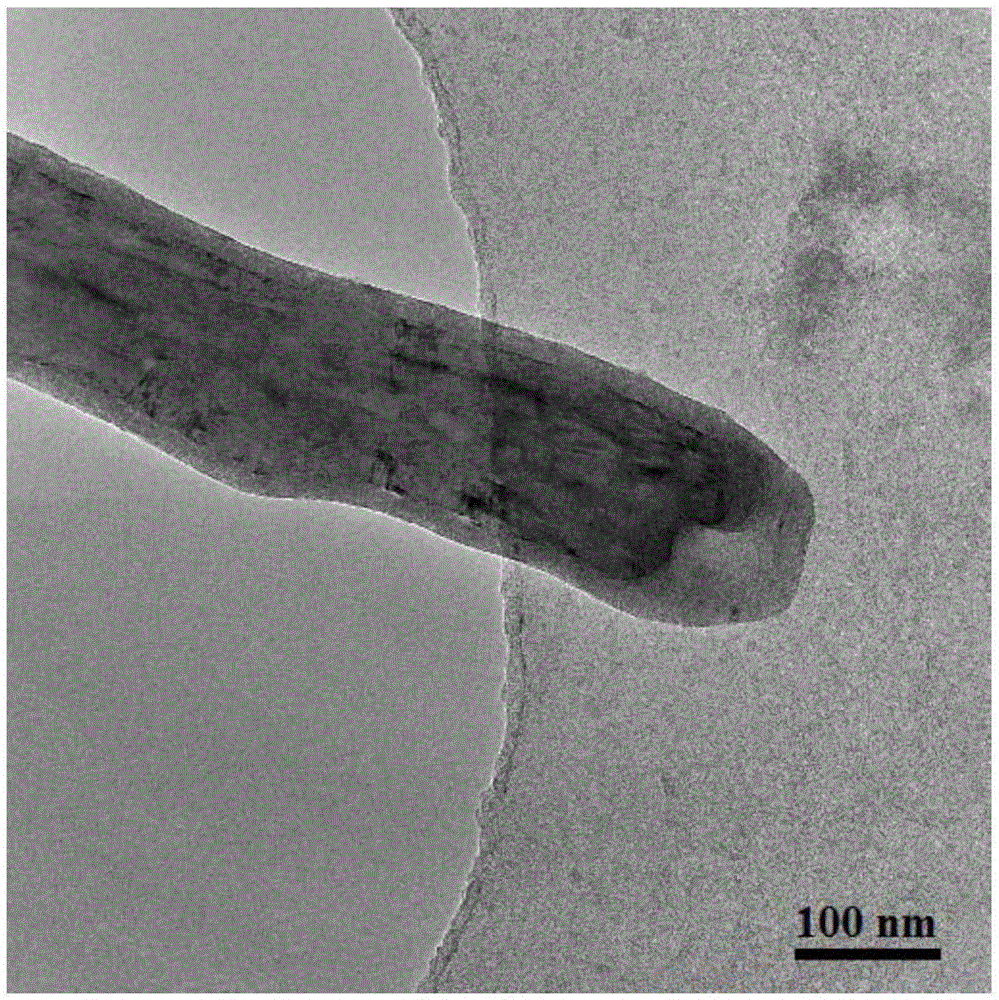

[0034] (1) Weigh 1.52g copper nitrate (Cu(NO 3 ) 2 .3H 2 O) and 1.5g of urea were dissolved in 10ml of water, 1.5g of multi-walled carbon nanotubes (CNTs) was added, and stirred at 150°C for 0.5h, after the aqueous solution was evaporated to dryness, the sample was cooled, and dried at 110°C for 12h to obtain carbon tube-supported copper hydroxide and basic copper nitrate samples (Cu / CNTs).

[0035] (2) The sample loaded with copper is mixed with ethanol to form a uniform suspension, the concentration of the sample is 0.1g / ml, coated on the surface of the glass sheet, evaporated to dryness and placed in the molecular layer deposition vacuum reaction chamber, the temperature of the chamber The temperature is 80°C, the cavity pressure is 50Pa, the cavity volume is 200ml, the carrier gas is nitrogen during the deposition process, and the flow rate is 1sccm-1000sccm, preferably 50sccm.

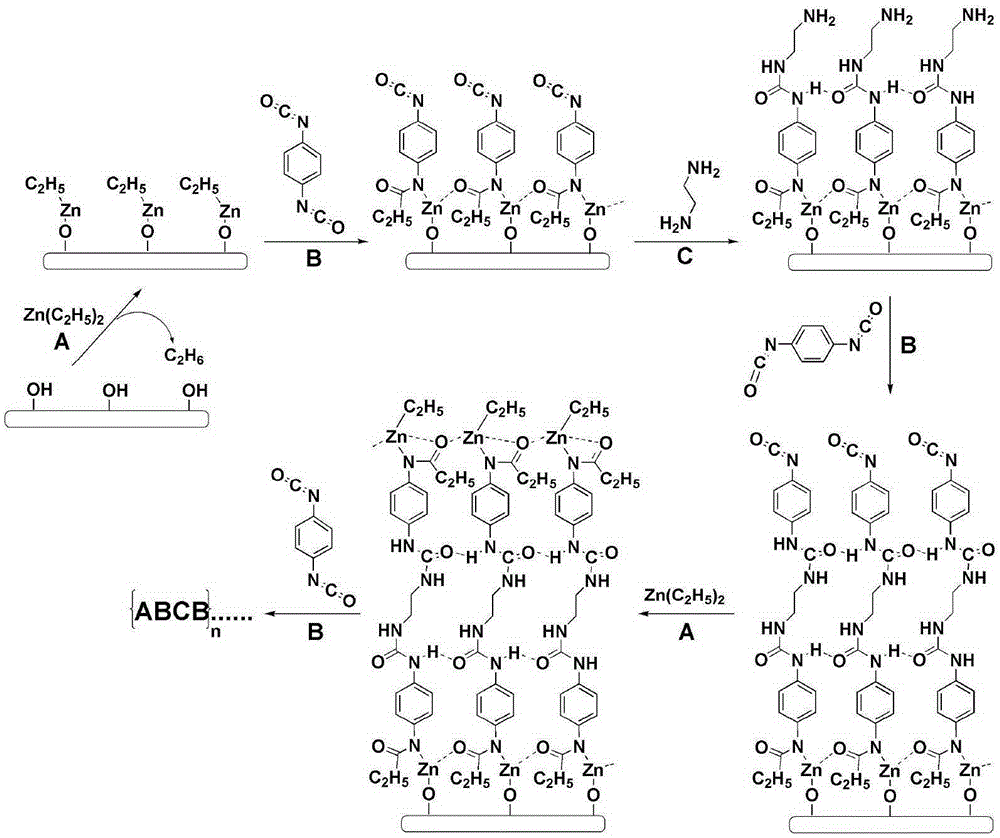

[0036] (3) Polyurea hybrid film deposited by molecular layer deposition technology:

[003...

Embodiment 2

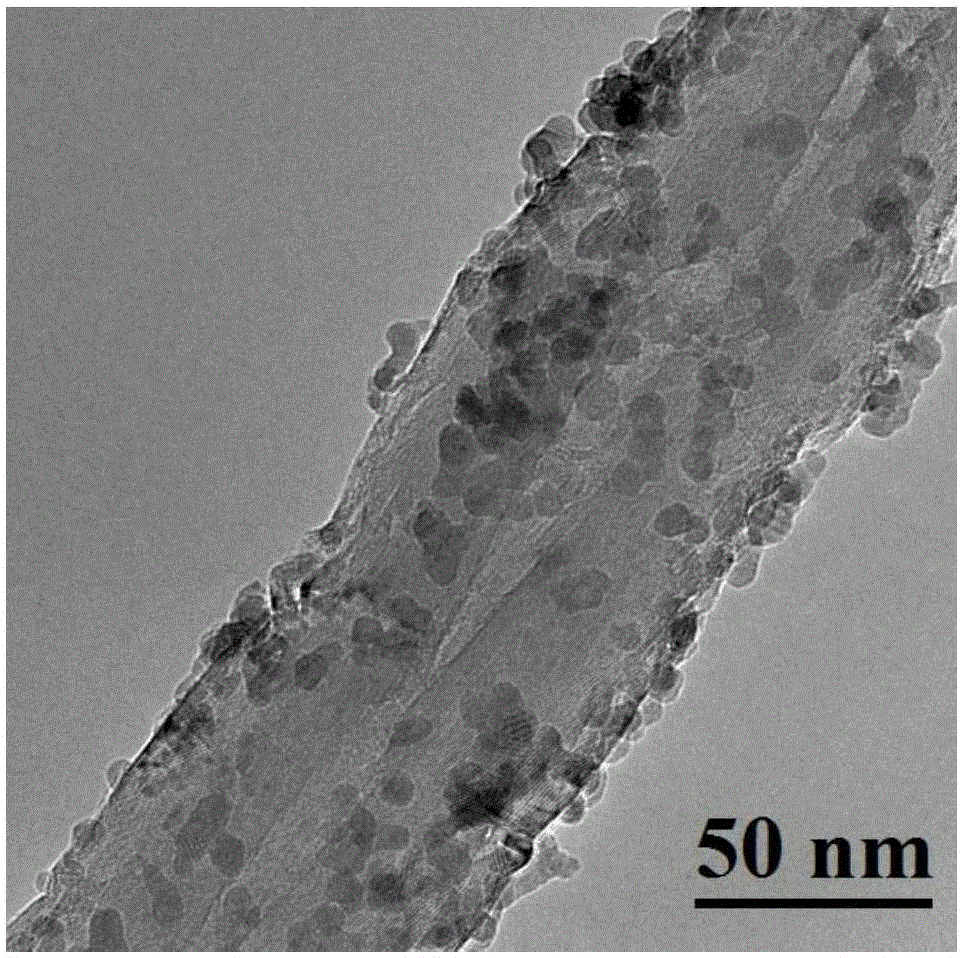

[0046] Adopt the same method of embodiment 1 to test, and the difference with embodiment 1 is that the number of deposition cycles increases by 120 cycles, and the yield of gamma-valerolactone in levulinic acid hydrogenation is improved to 74%, showing that Zn-poly The thickness of the urea hybrid film can change the number of Cu-ZnO binding sites, and its TOF is 11.2h -1 . This indicates that more Cu-ZnO interfaces can be obtained by increasing the thickness of molecular layer deposition, which improves the intrinsic activity of the catalyst.

Embodiment 3

[0048] (1) Weigh 1.0g of copper acetate and dissolve it in 10ml of ethanol, add 1.5g of porous alumina, stir at room temperature for 12h, and dry at 110°C for 12h to prepare an alumina-loaded copper acetate precursor (Cu / Al 2 o 3 ).

[0049] (2) The sample loaded with copper is mixed with ethanol to form a uniform suspension, the concentration of the sample is 0.15g / ml, coated on the surface of the glass sheet, evaporated to dryness and placed in the molecular layer deposition vacuum reaction chamber, the temperature of the chamber The temperature is 90°C, the chamber pressure is 40Pa, the chamber volume is 100ml, and the flow rate of argon (carrier gas) during the deposition process is 1sccm-1000sccm, preferably 30sccm. .

[0050] (3) Polyurea hybrid film deposited by molecular layer deposition technology:

[0051] (a) The first pulse of dimethyl zinc vapor chemisorption on Cu / Al 2 o 3 On the surface of the sample, pump air to remove the physically adsorbed part;

[005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com