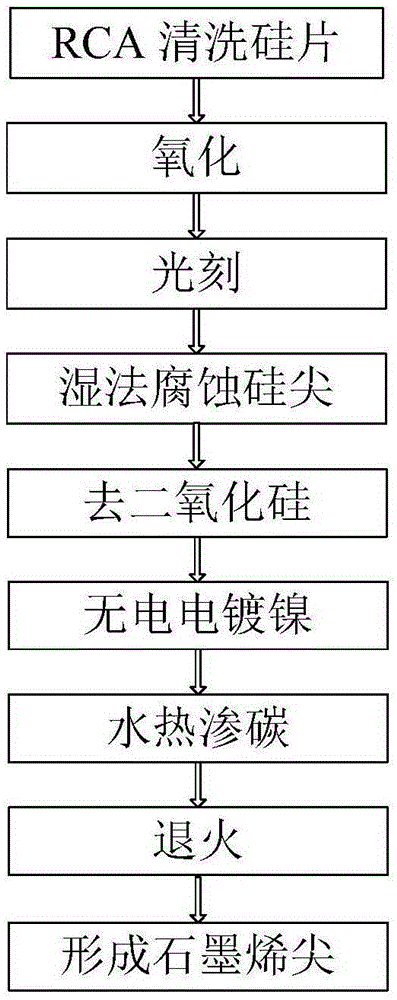

Preparation method for implementing electron field emission device by use of graphene

A launch device and graphene technology, applied in the field of micro-electromechanical systems, can solve problems such as difficult industrialization, difficult process, expensive equipment, etc., and achieve low cost, avoid complex process, and environment-friendly effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

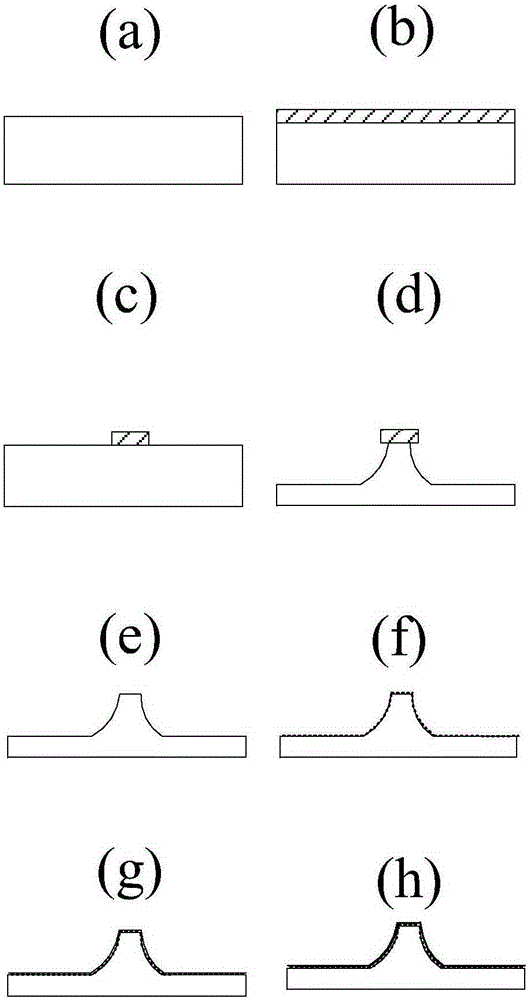

[0048] A preparation method of graphene electron field emission is as follows:

[0049] 1) Choose a 6-inch silicon wafer, n-type silicon with crystal orientation, resistivity 2-5Ω·cm, 500±50μm. The purpose of RCA cleaning solution is to remove particulate contamination (particles) and metal impurities. Liquid No.3 H 2 SO 4 (98% wt): H 2 o 2 (30%wt)=1:1 volume ratio mixing, remove organic contamination, soak for 15 minutes, rinse with hot and cold deionized water for 5 minutes each; No. 2 liquid NH 4 OH (28% wt): H 2 o 2 (30% wt): H 2 : O = 1:2:5 volume ratio mixing, removal of particulate impurities, boiling for 15 minutes, hot and cold deionized water for 5 minutes each; No. 1 liquid HCl (38%wt): H 2 o 2 (30% wt): H 2 : O = 1:2:7 volume ratio mixing, remove metal ions, boiling for 15 minutes, hot and cold deionized water rinse for 5 minutes each. Wafer such as figure 2 (a) shown.

[0050] 2) Dry oxygen for 15 minutes at a temperature of 960°C, then wet oxygen f...

Embodiment 2

[0057] A preparation method of graphene electron field emission is as follows:

[0058] 1) Select a 6-inch silicon wafer, n-type silicon with crystal orientation, resistivity 3Ω·cm, 550μm. Liquid No.3 H 2 SO 4 (98% wt): H 2 o 2 (30%wt)=1:1 volume ratio mix, soak for 30 minutes, remove organic contamination, rinse with hot and cold deionized water for 6 minutes each; No. 2 liquid NH 4 OH (28% wt): H 2 o 2 (30% wt): H 2 :O=1:2:5 volume ratio mixed, boiled and washed for 10 minutes, hot and cold deionized water rinsed for 6 minutes to remove particulate impurities; No. 1 liquid HCl (38%wt): H 2 o 2 (30% wt): H 2 :O=1:2:7 volume ratio mixing, remove metal ions, boil for 10 minutes, rinse with hot and cold deionized water for 6 minutes each. Wafer such as figure 2 (a) shown.

[0059] 2) First dry oxygen for 15 minutes at a temperature of 1060°C, then wet oxygen for 2 hours, and finally dry oxygen for 15 minutes, with an oxygen flow rate of 400ml / min. The thickness of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com