Method for preparing monochloromethyl trichlorosilane

A technology of monochloromethyltrichlorosilane and an evaporating kettle, which is applied in the field of preparing monochloromethyltrichlorosilane, can solve the problems of spontaneous combustion or explosion of reactants, difficulty in controlling the amount of reactants, and excessively long reaction time, and reduces the dosage , The effect of short response time and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

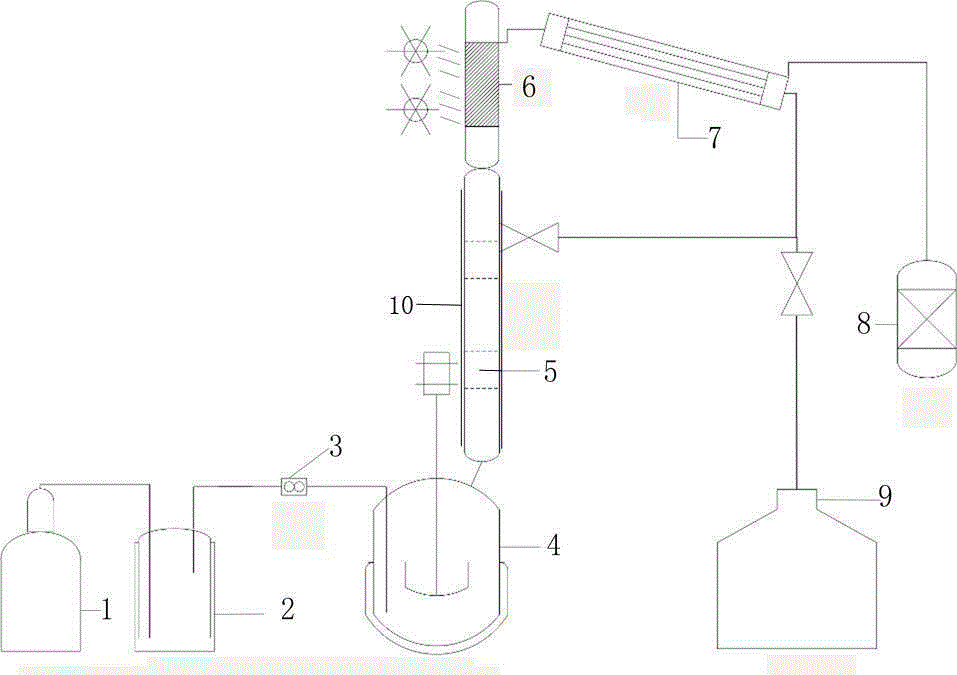

[0028] Gas phase chlorination reaction device such as figure 1 As shown, the top of the evaporator 4 is connected to the rectification tower 5 (the number of plates is 9-15), the top of the rectification tower 5 is connected to the ordinary glass reactor 6, the reactor 6 is connected to the condensing device 7, and the reflux of the condensing device 7 The pipe is connected to the upper part of the rectification tower 5; wherein the evaporation kettle 4 and the rectification tower 5 are covered with opaque materials. A heating device 10 is provided on the outer surface of the rectification tower 5 . The reactor 6 is irradiated by a 500W incandescent lamp. The reflux condensing device 10 is preliminarily used, and no cooling medium is required. Cl 2 The molar ratio with methyltrichlorosilane is 1:15 (Cl 2 The molar ratio to methyltrichlorosilane refers to the molar ratio of 5kg methyltrichlorosilane to the total amount of chlorine gas introduced; the same below). Add 5kg of...

Embodiment 2

[0031] Gas phase chlorination reaction device such as figure 1 As shown, the top of the evaporator is connected to a rectification tower, and the top of the rectification tower is connected to a reactor made of ordinary glass. The reactor is connected to a condensation device, and the return pipe of the condensation device is connected to the upper part of the rectification tower; Opaque material covering. A heating device is installed on the outer surface of the rectification tower. A 500W ultraviolet lamp irradiates the reactor. The cooling system of the reflux condensation zone is opened in advance, and no cooling medium is required. Cl 2 The molar ratio to methyltrichlorosilane is 1:20. Add 5kg of methyltrichlorosilane into the evaporator, turn on the electromagnetic stirring, heat the evaporator, and turn on the heating device of the rectification tower; Below the silane liquid level; control the heating speed of the evaporator to make the reflux moderate, and at the...

Embodiment 3

[0034] Gas phase chlorination reaction device such as figure 1 As shown, the top of the evaporator is connected to a rectification tower, and the top of the rectification tower is connected to a reactor made of ordinary glass. The reactor is connected to a condensation device, and the return pipe of the condensation device is connected to the upper part of the rectification tower; Opaque material covering. A heating device is installed on the outer surface of the rectification tower. A 500W incandescent lamp illuminates the reactor. The cooling system of the reflux condensation zone is opened in advance, and no cooling medium is required. Cl 2 The molar ratio to methyltrichlorosilane is 1:25. Add 5kg of methyltrichlorosilane into the evaporator, turn on the electromagnetic stirring, heat the evaporator, and turn on the heating device of the rectification tower; Below the silane liquid level; control the heating speed of the evaporator to make the reflux moderate, and at t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com