Environmentally friendly fluorescent waterborne polyurethane and preparation method thereof

A water-based polyurethane, environment-friendly technology, applied in the field of environment-friendly fluorescent water-based polyurethane and its preparation, can solve the problems of pollution, human poisoning to the environment, unstable content, etc., and achieve the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

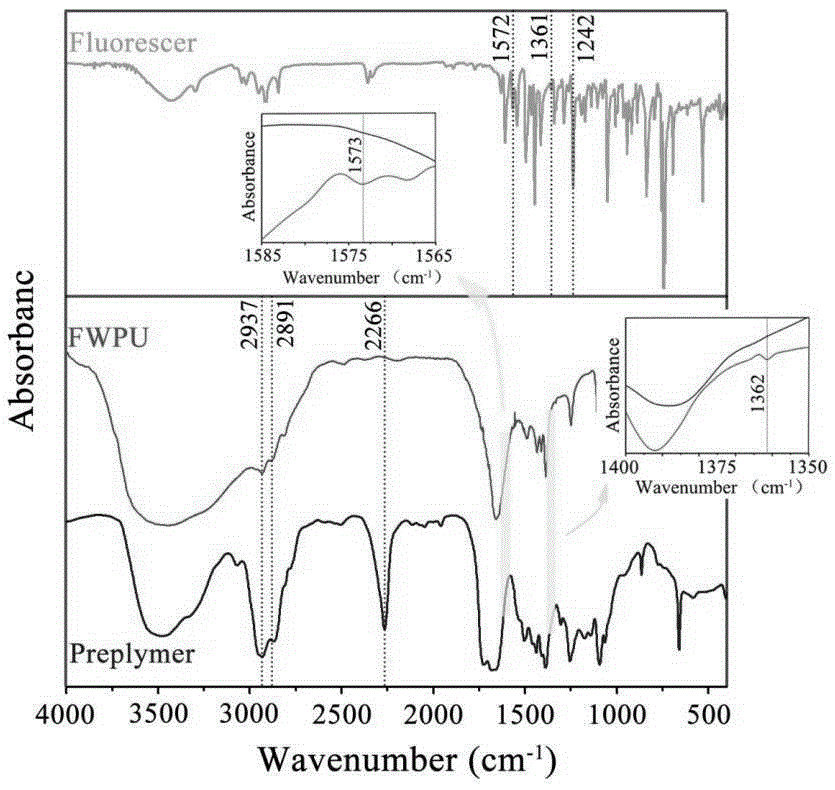

[0034](1) 100 parts of polypropylene glycol with a number average molecular weight of 2000, 48 parts of isophordione diisocyanate, 1,4 - 4 parts of butanediol and 0.02 parts of dibutyltin laurate are added to the reaction vessel, and the temperature is raised to 85°C for 3 hours to prepare the prepolymer under continuous stirring;

[0035] (2) Add 8 parts of dimethylolpropionic acid and 10 parts of acetone to the obtained prepolymer, and maintain the reaction at 85°C for 2 hours to obtain a prepolymer with hydrophilic groups;

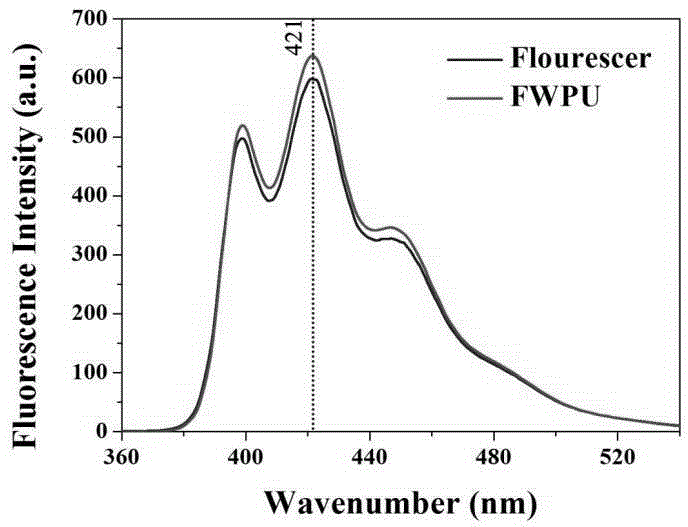

[0036] (3) Add 1 part of fluorescent agent and 20 parts of acetone to the prepolymer obtained in (2), and continue to react at 85°C for 2 hours in a nitrogen atmosphere to obtain a prepolymer containing a fluorescent chain extender;

[0037] (4) Use 6 parts of triethylamine to neutralize the prepolymer, and under the action of high shear force, disperse the prepolymer in 373 parts of deionized water, stir for 1 hour, remove acetone under reduced pressur...

Embodiment 2

[0039] (1) 80 parts of polyethylene glycol with a number average molecular weight of 4000, 2,4 - 35 parts of toluene diisocyanate, 1,6 - 8 parts of hexanediol and 0.01 part of stannous octoate were added to the reaction vessel, and the temperature was raised to 75°C for 3 hours under continuous stirring to prepare the prepolymer;

[0040] (2) Add 8 parts of dimethylol butyric acid and 15 parts of butanone to the obtained prepolymer, and maintain the reaction at 75°C for 3 hours to obtain a prepolymer with a block structure;

[0041] (3) Add 0.5 parts of fluorescent agent and 10 parts of butanone to the prepolymer obtained in (2), and continue to react at 75°C for 2 hours to obtain a prepolymer containing fluorescent chain extender;

[0042] (4) Use 5.5 parts of triethylamine to neutralize the prepolymer, and under the action of high shear force, disperse the prepolymer in 243 parts of deionized water, stir for 1 hour, remove butanone under reduced pressure for reuse, and obta...

Embodiment 3

[0044] (1) 100 parts of polycarbonate diol with a number average molecular weight of 3000, 10 parts of isophordione diisocyanate, 25 parts of hexamethylene diisocyanate, 1,4 - 3 parts of butanediol, 3 parts of diethylene glycol and 0.01 part of dimethylcyclohexylamine, with continuous stirring, the temperature was raised to 80°C for 3 hours to prepare a prepolymer;

[0045] (2) Add 7 parts of dimethylolsulfonate with a molecular weight of 1000 and 10 parts of methyl ethyl ketone to the obtained prepolymer, and maintain the reaction at 80°C for 2.5 hours to obtain a prepolymer with hydrophilic groups;

[0046] (3) Add 1.5 parts of fluorescent agent and 30 parts of methyl ethyl ketone to the prepolymer obtained in (2), and continue to react at 80°C for 2.5 hours under the protection of nitrogen atmosphere to obtain a prepolymer containing fluorescent chain extender;

[0047] (4) Use 5.5 parts of triethylamine to neutralize the prepolymer, and under the action of high shear force...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com