Synthesis method of related polypeptide

A synthetic method and type of technology, applied in the field of peptide-like synthesis, can solve the problems of limitations, harshness, and unsuitability for large-scale synthesis, and achieve the effect of facilitating polymerization and increasing the reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

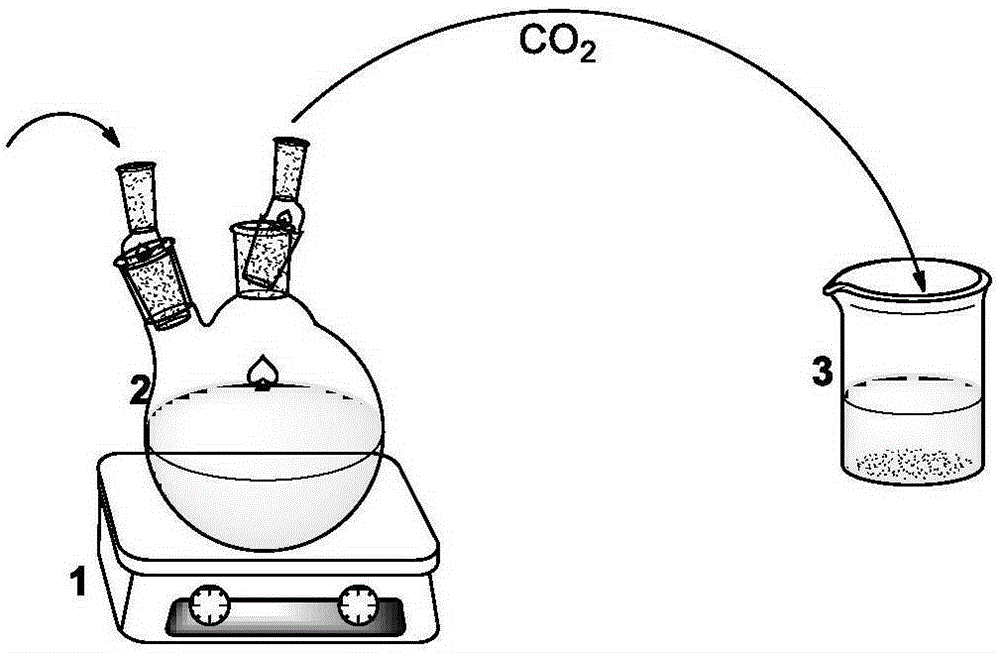

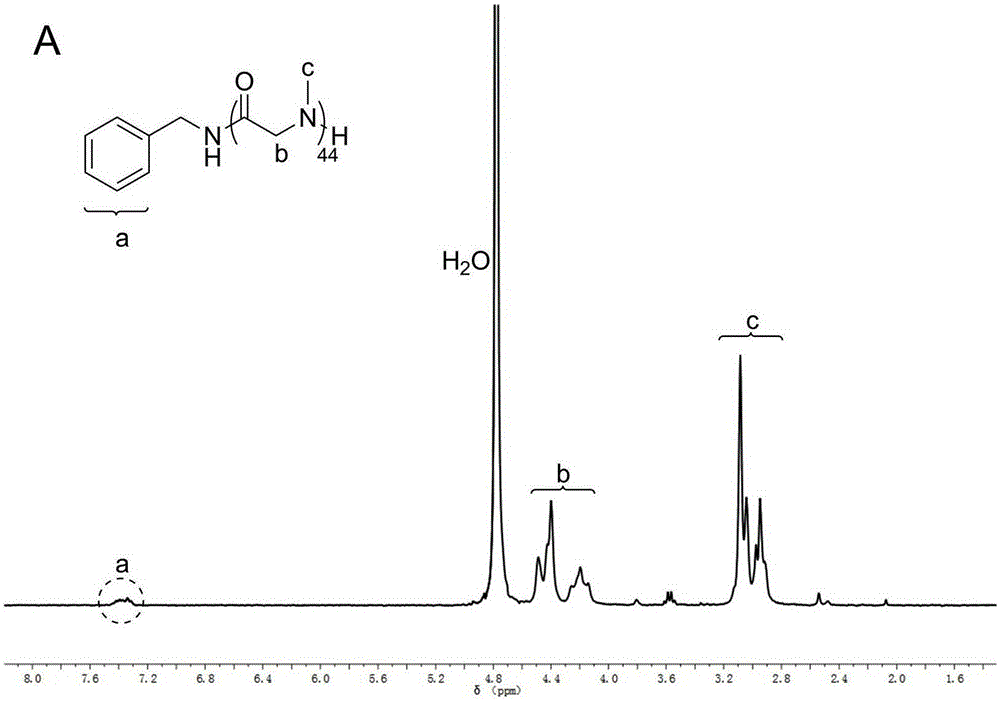

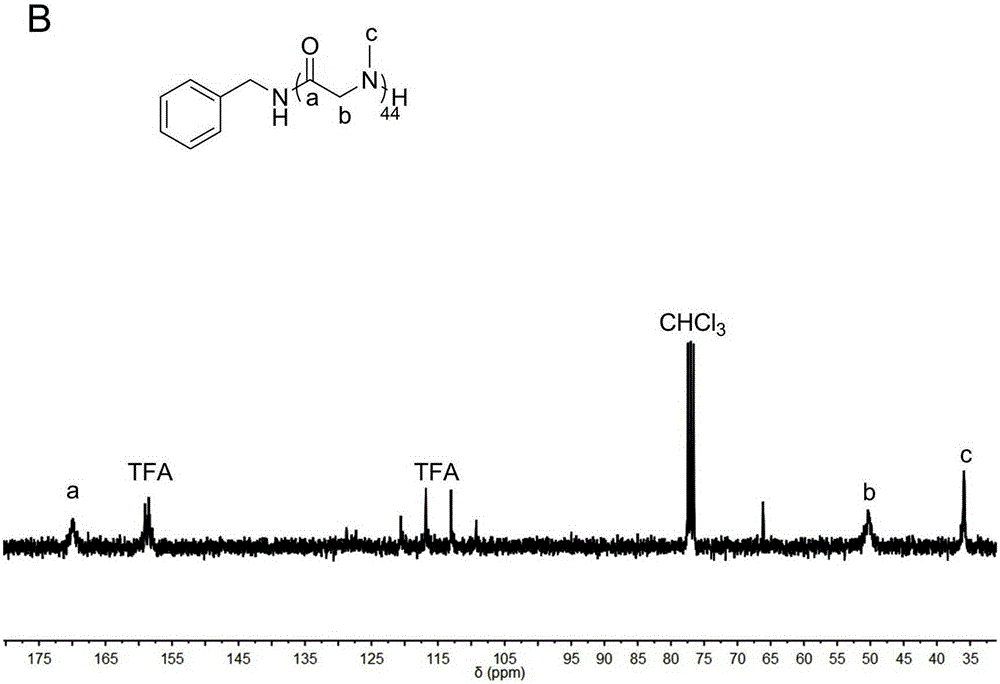

[0035] Such as figure 1 As indicated, under the condition of nitrogen flow, N-methyl substituted glycine-N-carboxy anhydride (0.2581g, 2.3mmol) was dissolved in 2.3mL of anhydrous acetonitrile, after complete dissolution, benzylamine (10uL, 0.092mmol) added to the solution ([monomer] 0 / [initiator 0 ]=25). The reaction solution was reacted at room temperature under nitrogen flow. After reacting for 4 hours, the reaction liquid was added into excess diethyl ether to precipitate a polymer, and then the polymer was vacuum-dried. polymer structure through 1 HNMR with 13 CNMR identification (see figure 2 and image 3 ), the molecular weight and degree of dispersion of the polymer are measured by GPC (gel permeation chromatography). GPC test conditions: flow rate 1mL / min, mobile phase DMF, temperature 50°C. From Figure 4 In the reaction kinetic curve, we found that the reaction rate was significantly increased under the action of nitrogen flow. (number average molecular...

Embodiment 2

[0037] Under the condition of nitrogen flow, N-methyl-substituted glycine-N-carboxy anhydride (3.097g, 27.6mmol) was dissolved in 27.6mL of anhydrous dichloromethane, after complete dissolution, propylamine (7.5uL, 0.092 mmol) was added to the solution ([monomer] 0 / [initiator 0 ]=300). The reaction solution was reacted at room temperature under nitrogen flow. After reacting for 4 hours, the reaction liquid was added into excess diethyl ether to precipitate a polymer, and then the polymer was vacuum-dried. polymer structure through 1 HNMR with 13 CNMR identification, molecular weight and dispersion of the polymer are measured by GPC (gel permeation chromatography). GPC test conditions: flow rate 1mL / min, mobile phase DMF, temperature 50°C. (number average molecular weight 20.7 kg / mol; molecular weight distribution 1.08; yield 92.1%).

Embodiment 3

[0039] Under nitrogen flow conditions, N-ethyl substituted glycine-N-carboxy anhydride (1.1860g, 9.2mmol) was dissolved in 9.2mL of anhydrous acetonitrile, after complete dissolution, benzylamine (10uL, 0.092mmol) added to the solution ([monomer] 0 / [initiator 0 ]=100). The reaction solution was reacted at room temperature under nitrogen flow. After reacting for 8 hours, the reaction liquid was added into excess diethyl ether to precipitate the polymer, and then the polymer was vacuum-dried. polymer structure through 1 HNMR with 13 CNMR identification, molecular weight and dispersion of the polymer are measured by GPC (gel permeation chromatography). GPC test conditions: flow rate 1mL / min, mobile phase DMF, temperature 50°C. (number average molecular weight 1.8 kg / mol; molecular weight distribution 1.22; yield 86.1%).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com