Low-hygroscopicity anti-ageing epoxy-resin-based package adhesive

An epoxy resin and anti-aging technology, which is applied in the direction of epoxy resin glue, adhesive, adhesive type, etc., can solve the problem of the decrease of light transmittance of packaging materials, the reduction of LED luminous efficiency and luminous brightness, and the difficulty of packaging and erosion of electrical insulation Sexuality and other issues, to achieve the effect of good light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

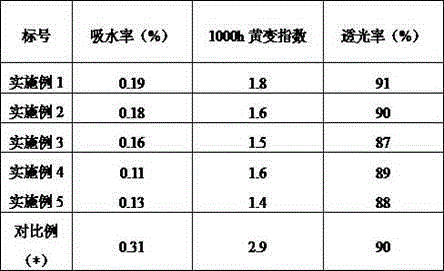

Examples

Embodiment 1

[0019] A low-humidity anti-aging epoxy resin-based encapsulant, comprising the following raw materials in parts by weight: 56 parts of hydrogenated bisphenol A epoxy resin, 6103 parts of nylon, 2 parts of poly-4-methyl-1-pentene, hydroxyl 1 part of silicone oil, 2 parts of vinyl tert-carbonate, 1 part of zirconia, 1 part of magnesium oxide, 2 parts of 2-hydroxy-4-N-octyloxybenzophenone, 3 parts of maleic anhydride grafted polypropylene, 9 parts of diphenol diphenyl and 2 parts of dimethylimidazole.

[0020] The preparation process of the above-mentioned low-humidity anti-aging epoxy resin-based encapsulant comprises the following steps:

[0021] Weigh the raw materials of the above-mentioned parts by mass;

[0022] Heat and stir nylon 610, poly-4-methyl-1-pentene, vinyl tert-carbonate, zirconia, magnesium oxide, maleic anhydride grafted polypropylene, diphenol diphenyl and dimethylimidazole in the raw materials ;

[0023] Then add hydrogenated bisphenol A type epoxy resin, ...

Embodiment 2

[0027] A low-humidity anti-aging epoxy resin-based encapsulant, comprising the following raw materials in parts by weight: 70 parts of hydrogenated bisphenol A epoxy resin, 6106 parts of nylon, 5 parts of poly-4-methyl-1-pentene, hydroxyl 3 parts of silicone oil, 4 parts of vinyl tert-carbonate, 2 parts of zirconia, 3 parts of magnesium oxide, 3 parts of 2-hydroxy-4-N-octyloxybenzophenone, 5 parts of maleic anhydride grafted polypropylene, 15 parts of m-phenylenediamine and 5 parts of dimethylimidazole.

[0028] The preparation process of the above-mentioned low-humidity anti-aging epoxy resin-based encapsulant comprises the following steps:

[0029] Weigh the raw materials of the above-mentioned parts by mass;

[0030] Heat and stir nylon 610, poly-4-methyl-1-pentene, vinyl tertiary carbonate, zirconia, magnesium oxide, maleic anhydride grafted polypropylene, m-phenylenediamine and dimethylimidazole in the raw materials ;

[0031] Then add hydrogenated bisphenol A type epo...

Embodiment 3

[0035] A low-humidity anti-aging epoxy resin-based encapsulant, comprising the following raw materials in parts by weight: 85 parts of hydrogenated bisphenol A epoxy resin, 10 parts of nylon 61010 parts, 8 parts of poly-4-methyl-1-pentene, hydroxyl 5 parts of silicone oil, 6 parts of vinyl tert-carbonate, 3 parts of zirconia, 4 parts of magnesium oxide, 5 parts of 2-hydroxy-4-N-octyloxybenzophenone, 8 parts of maleic anhydride grafted polypropylene, 20 parts of m-phenylenediamine and 8 parts of dimethylimidazole.

[0036] The preparation process of the above-mentioned low-humidity anti-aging epoxy resin-based encapsulant comprises the following steps:

[0037] Weigh the raw materials of the above-mentioned parts by mass;

[0038] Heat and stir nylon 610, poly-4-methyl-1-pentene, vinyl tertiary carbonate, zirconia, magnesium oxide, maleic anhydride grafted polypropylene, m-phenylenediamine and dimethylimidazole in the raw materials ;

[0039] Then add hydrogenated bisphenol ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com