A kind of preparation method of wood adhesive with hydrolyzed collagen as raw material

A technology for hydrolyzing collagen and wood adhesives, which is applied in the preparation of animal glue or gelatin, protein adhesives, adhesives, etc., and can solve the problem of low molecular weight of hydrolyzed collagen, reducing the effectiveness of collagen, and environmental pollution, etc. problems, to achieve the effect of simple preparation process, alleviating the shortage of petrochemical raw materials, and avoiding environmental hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] (1) Weigh 10 parts of hydrolyzed collagen (abbreviated as CH, the same below) and add 50 parts of deionized water into the reaction kettle, stir at room temperature for 10 minutes to dissolve, and obtain a uniformly mixed solution. Adjust the pH to 9.0 and the temperature to 60 ℃;

[0052] (2) Add 2 parts of γ-glycidyl etheroxypropyl trimethoxysilane (GPTMS) to the hydrolyzed collagen solution in step (1), maintain the pH of the system at 9.0 and the temperature at 60 °C, and stir for 10 h , the hydrolyzed collagen-based adhesive can be obtained.

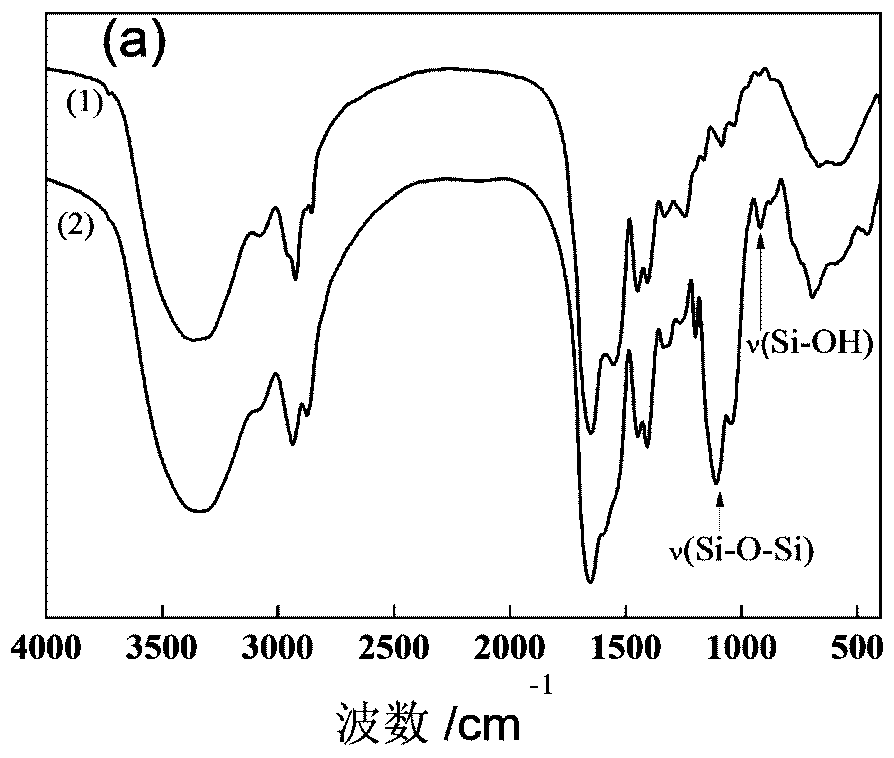

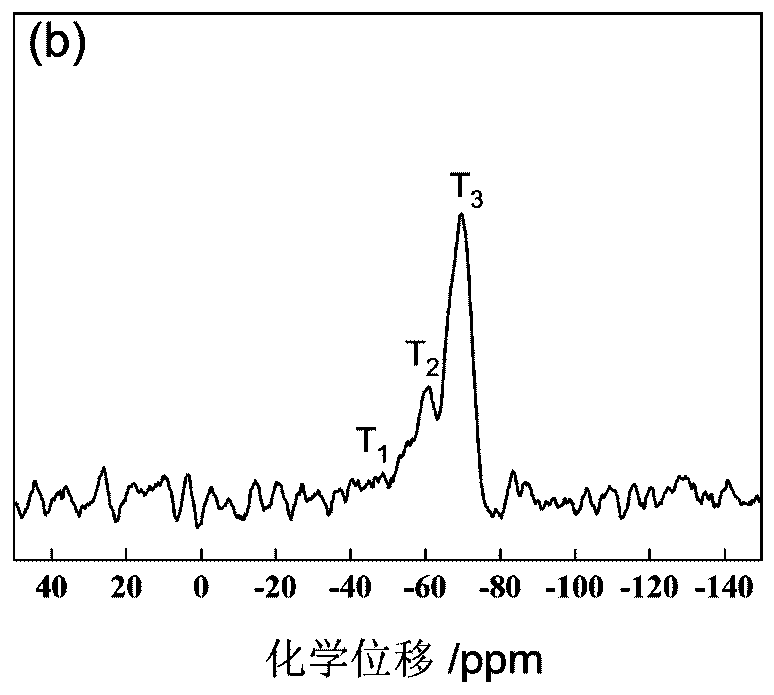

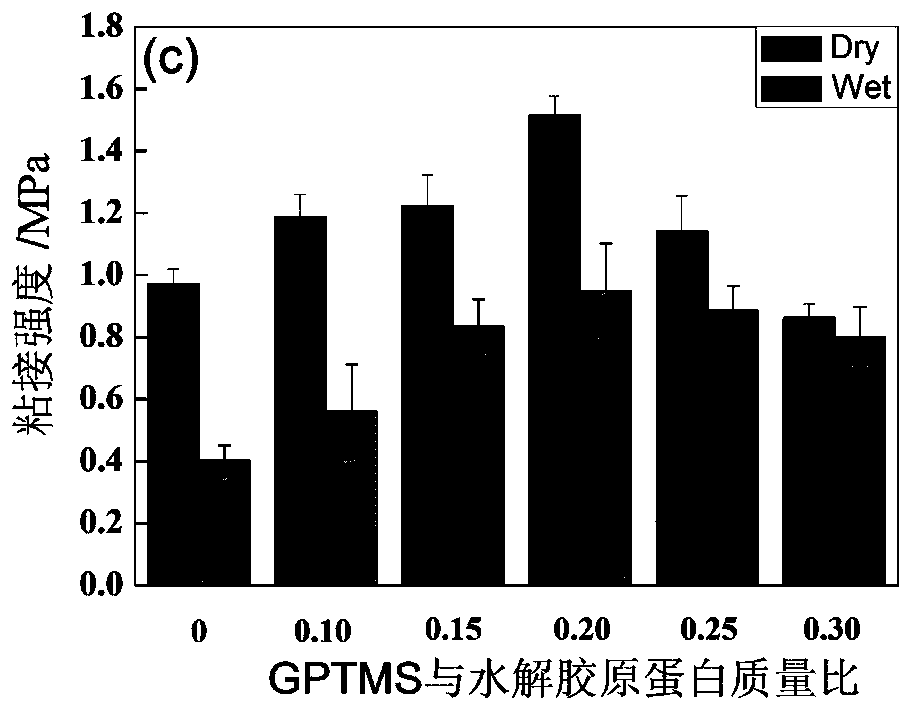

[0053] The prepared GPTMS cross-linked hydrolyzed collagen adhesive (GPTMS-CH) was used for birch bonding, and the dry strength and wet strength were tested. The characterization of the product and the test results of the bonding strength are as follows: Figure 1-3 shown. Depend on Figure 1-3 It can be seen that GPTMS has successfully cross-linked hydrolyzed collagen, and the product structure formed by silanol condensa...

Embodiment 2

[0055] (1) Weigh 10 parts of hydrolyzed collagen and 100 parts of deionized water into the reaction kettle, stir at room temperature for 10 minutes to dissolve, and obtain a uniformly mixed solution. Adjust the pH to 10.0 and the temperature to 50 °C;

[0056] (2) Add 2 parts of γ-glycidyl etheroxypropyltriethoxysilane (GPTES) to the hydrolyzed collagen solution in step (1), maintain the pH of the system at 10.0 and the temperature at 50 °C, and stir for 11 h, the hydrolyzed collagen-based adhesive can be obtained.

[0057] The prepared GPTES cross-linked hydrolyzed collagen adhesive (GPTES-CH) was used for birch bonding, and the dry strength and wet strength were tested. The characterization of the product and the test results of the bonding strength are as follows: Figure 4-6 shown. Depend on Figure 4-6 It can be seen that GPTES has successfully cross-linked hydrolyzed collagen, and the product structure formed by silanol polycondensation reaction is mainly a three-dime...

Embodiment 3

[0059] (1) Weigh 10 parts of hydrolyzed collagen and 80 parts of deionized water into the reaction kettle, stir at room temperature for 10 minutes to dissolve, and obtain a uniformly mixed solution, adjust the pH to 7.0, and the temperature to 40 °C;

[0060] (2) Add 2.5 parts of 3-aminopropyltrimethoxysilane (APTMS) and 1 part of glutaraldehyde to the hydrolyzed collagen solution in step (1), adjust the system temperature to 50 °C and pH after stirring for 2 h 8.0, stirring and reacting for 8 h, the hydrolyzed collagen-based adhesive can be obtained.

[0061] The prepared APTMS cross-linked hydrolyzed collagen adhesive (APTMS-CH) was used for birch bonding, and the dry strength and wet strength were tested. The characterization of the product and the test data of the bonding strength are as follows: Figure 7 , 8 shown. Depend on Figure 7 , 8 It can be seen that APTMS has successfully cross-linked hydrolyzed collagen, and when the mass ratio of APTMS to hydrolyzed colla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com