A magnetic microsphere of immobilized earthworm fibrinolytic enzyme and its preparation method

A technology of magnetic microspheres and plasmin, applied in directions such as being fixed on/in an organic carrier, can solve the problems of difficult industrial production, complicated purification procedures, low economic benefits, etc., and achieves easy operation and stable pH. The effect of good performance and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

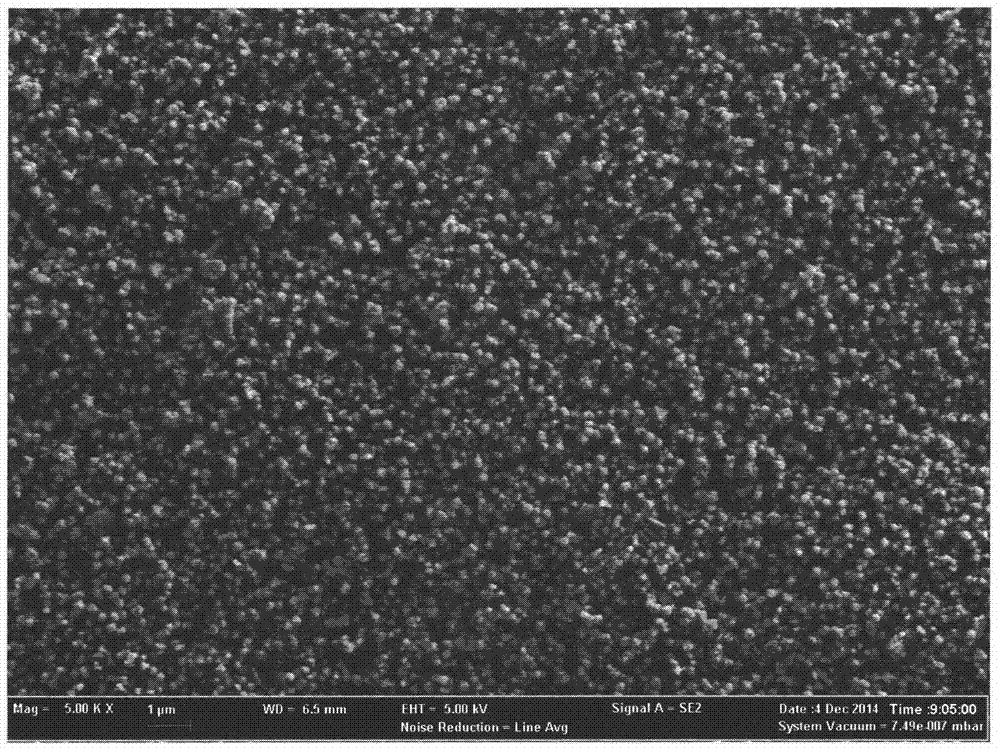

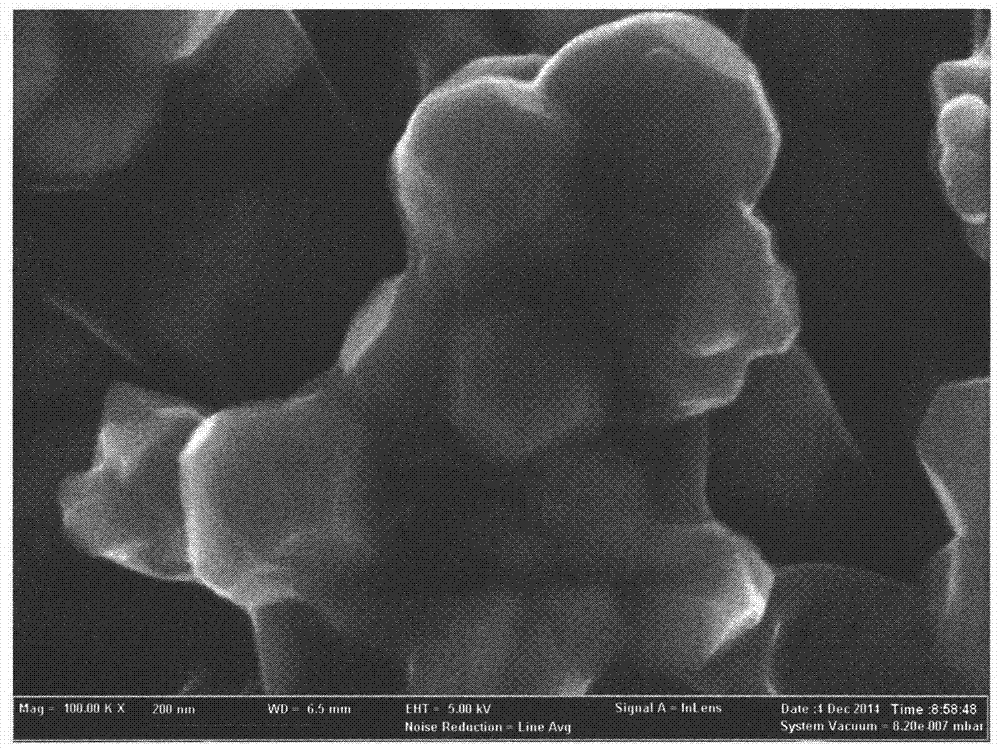

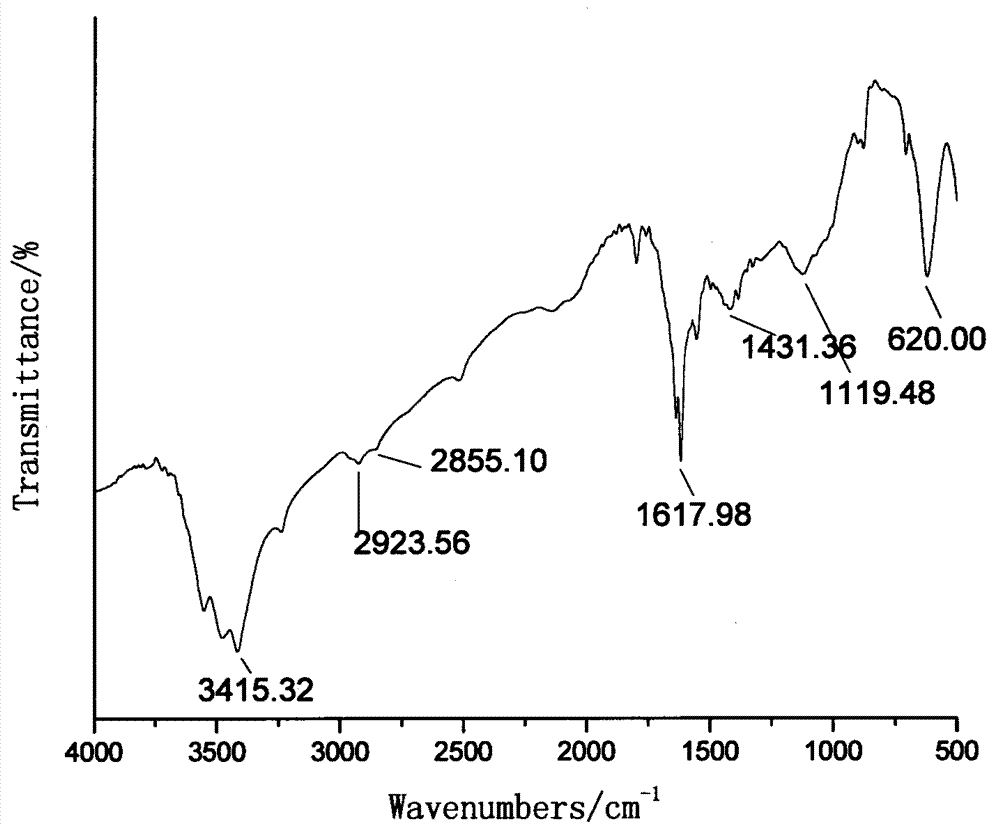

[0041] Measure 100mL of liquid paraffin and 2mL of span-80 into a 250mL three-neck flask, heat and stir in a water bath at 45°C for 1 hour to make an oil phase; weigh 0.2g of chitosan, dissolve it with 20mL of 3% acetic acid solution, and wait for chitosan After the sugar is completely dissolved, add 0.6g of Fe 3 o 4 , ultrasonically dispersed for 10 min; prepare a chitosan solution with a concentration of 5 mg / ml, then add it to the oil phase, stir at 300 rpm for half an hour to make the solution form an emulsion system, slowly add 3 mL of glutaraldehyde with a mass of 25%, and continue Stir for 1 hour, adjust the pH to about 10 with 1.0 mol / L NaOH solution, continue the reaction for 1 hour, stop the reaction, separate with a magnet, wash with petroleum ether, ethanol and deionized water, and dry in vacuum to obtain magnetic chitosan microspheres .

[0042] The particle size of the magnetic chitosan microspheres is shown in Table 1.

Embodiment 2

[0044] Measure 100mL of liquid paraffin and 3mL of span-80 into a 250mL three-neck flask, heat and stir in a water bath at 30°C for 2 hours to make an oil phase; weigh 0.8g of chitosan, dissolve it with 20mL of 5% acetic acid solution, and wait for chitosan After the sugar is completely dissolved, add 0.6g of Fe 3 o 4 , ultrasonically dispersed for 20min; prepared into a chitosan solution with a concentration of 6.5mg / ml, then added to the oil phase, stirred at 400rpm for half an hour to make the solution form an emulsion system, and slowly added 5mL of glutaraldehyde with a mass of 25%. Continue stirring for 2 hours, adjust the pH to about 9 with 1.0mol / L NaOH solution, stop the reaction after continuing the reaction for 2 hours, separate with a magnet, wash with petroleum ether, ethanol and deionized water, and dry in vacuum to obtain magnetic chitosan microparticles. ball.

[0045] The particle size of the magnetic chitosan microspheres is shown in Table 1.

Embodiment 3

[0047] Measure 100mL of liquid paraffin and 2.5mL of span-80 into a 250mL three-neck flask, heat and stir in a 40°C water bath for 2 hours to make an oil phase; weigh 1g of chitosan, dissolve it with 20mL of 3% acetic acid solution, and wait for chitosan After the sugar is completely dissolved, add 0.6g of Fe3O4 and ultrasonically disperse for 15 minutes; prepare a chitosan solution with a concentration of 8.1mg / ml, then add it to the oil phase, stir at 500rpm for half an hour to make the solution form an emulsion system, and then slowly add 10mL of glutaraldehyde with a mass of 25%, continue to stir for 1.5h, adjust the pH to about 9.5 with 1.0mol / L NaOH solution, stop the reaction after 1.5h, separate with a magnet, wash with petroleum ether, ethanol and deionized water , and vacuum-dried to obtain magnetic chitosan microspheres.

[0048] The particle size of the magnetic chitosan microspheres is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com