Determination method for austenitic grain size of pearlite type wire rod

A technology of austenite grain and measurement method, which is applied in the field of measurement of austenite grain size of pearlitic wire rod, which can solve the problem of austenite grain growth and difficulty in reflecting the austenite grain of wire rod High success rate, easy to understand, and good reproducibility of results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below through specific examples.

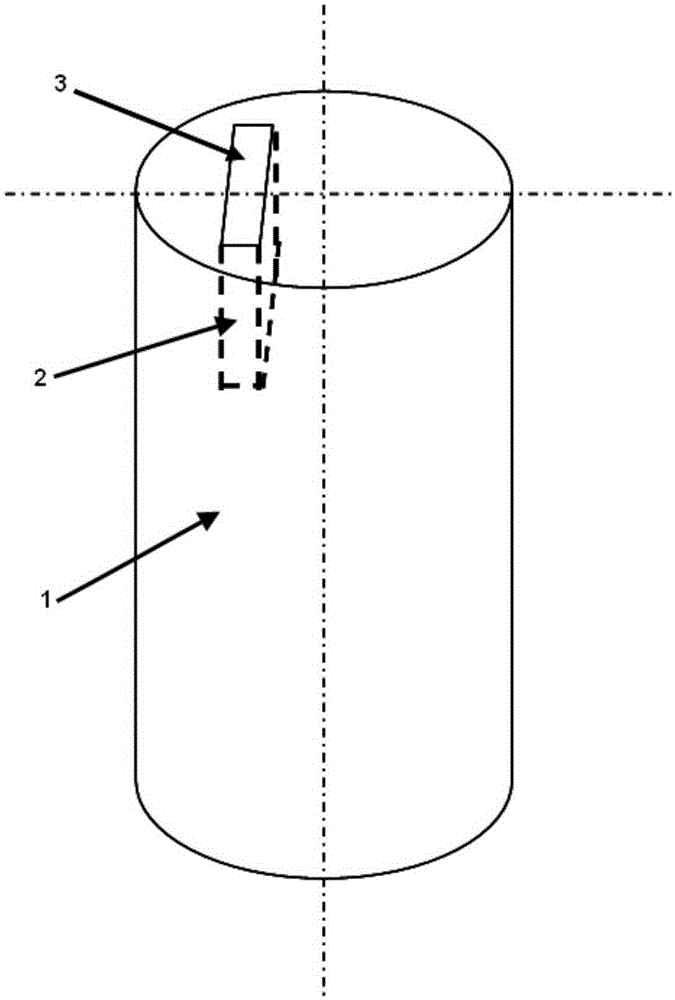

[0033] according to figure 1 In the middle position, use wire cutting to cut a small piece from the pearlitic wire rod 1 to be tested as the sample 2, and the interception position is the area near the vertical line of the radius of the cross section of the wire rod 1 (the cross section is about 1 / 4 along the diameter) , the size of sample 2 is 20mm×10mm×5mm (cuboid). After grinding all samples 2 step by step with 220#, 340#, 380#, 400#, 600#, 1400#, 1800# metallographic sandpaper, select diamond polishing agents with particle sizes of 4μm, 3μm, and 1μm to test in turn Sample 2 was mechanically polished. Then electrolytic polishing is carried out, the electrolytic solution is perchloric acid ethanol solution with a concentration of 5% by volume, the parameters of electrolytic polishing are: voltage 24V, current 0.2-0.3A, polishing time 15-30s. The preparation requirements of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com