Crystal mooncake capable of being industrially produced and making method thereof

A technology of moon cakes and crystals, applied in the field of crystal moon cakes and its preparation, can solve the problems of unfavorable product quality control, unfavorable expansion of production, easy release of water from cake skin, etc., achieve good mechanical operability, improve mechanical operability, and reduce microbial pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

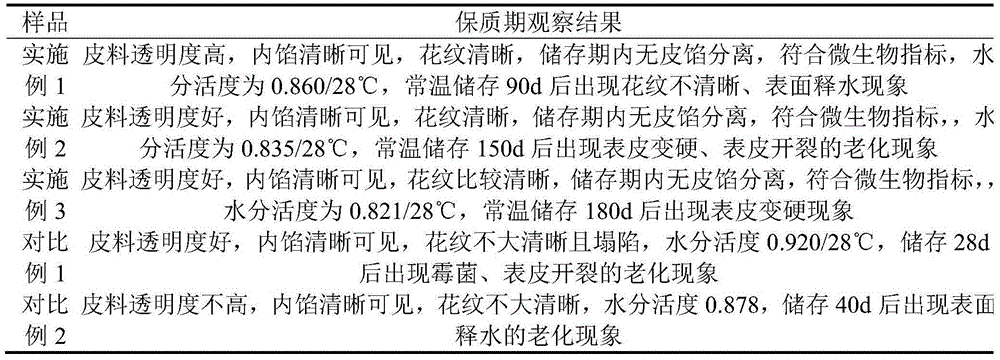

Examples

Embodiment 1

[0040] (1) Pour 30.0kg of maltose syrup into a sandwich pot, heat to 40-45°C, add 9.0kg of tapioca modified starch (hydroxypropyl distarch phosphate HA-08, Hangzhou Prostar Starch Co., Ltd.), 0.05kg of Yi Dissolved agar (Qingdao Youlide, RS600, the same below) and 0.01kg molecularly distilled monoglyceride, stirred at a speed of 10-15r / min, to obtain a smooth and delicate batter without obvious particles;

[0041] (2) Add 0.1kg potassium sorbate, 3.0kg trehalose, 10.0kg sucrose, 10.0kg glucose, 30.74kg water and 1.0kg peanut oil into the jacketed pot, turn on the heating, heat up while stirring, and the mixture obtained in step (1) Stir the batter evenly;

[0042] (3) Turn off the heating when the central temperature of the boil rises to 90-95°C, keep stirring, keep warm for 10 minutes, until fully cooked; finally add 1.0kg of edible glycerin and 5.0kg of maltitol with a solid content of 70% Stir evenly in the mature material;

[0043] (4) Dilute 0.1kg of malic acid with a s...

Embodiment 2

[0047] (1) Pour 35.0kg of glucose syrup into a jacketed pot, heat to 40-45°C and add 10.0kg of tapioca modified starch (acetylated double starch adipate MYS-600, Guangxi Mingyang Biochemical Technology Co., Ltd.), 0.04 kg of soluble agar and 0.02kg of calcium stearoyl lactylate, stirred at a speed of 10-15r / min, to obtain a smooth and delicate batter without obvious particles;

[0048] (2) Add 0.05kg of sodium dehydroacetate, 2.0kg of trehalose, 10kg of sucrose, 5kg of glucose, 29.79kg of water and 2.0kg of sunflower oil into the jacketed pot, turn on the heating, heat up while stirring, and obtain from step (1) Stir the batter evenly;

[0049] (3) Turn off the heating when the central temperature of the infusion rises to 90-95°C, keep stirring, keep warm for 10 minutes, until fully cooked; finally add 2.0kg of edible glycerin and 4.0kg of sorbitol with a solid content of 70% Stir evenly in the matured material;

[0050](4) Dilute 0.1kg of malic acid with a small amount of s...

Embodiment 3

[0054] (1) Pour 38.0kg of maltose syrup into a jacketed pot, heat to 40-45°C, add 11kg of tapioca modified starch (hydroxypropyl distarch phosphate HA-08, Hangzhou Prostar Starch Co., Ltd.), 0.02kg of soluble starch Agar and 0.03kg of sodium stearoyl lactylate were stirred at a speed of 10-15r / min to obtain a smooth and delicate batter without obvious particles;

[0055] (2) Add 0.03kg natamycin, 1.0kg trehalose, 10kg glucose, 30.82kg water and 3.0kg soybean oil into the sandwich pot, turn on the heating, heat up while stirring, and stir evenly with the batter obtained in step (1) ;

[0056] (3) Turn off the heating when the central temperature of the cooking rises to 90-95°C, keep stirring, keep warm for 10 minutes, until fully matured; finally add 3.0kg edible glycerin and 3.0kg maltitol with a solid content of 80% to the matured Stir evenly in the material;

[0057] (4) Dilute 0.1kg of malic acid with a small amount of sterile water, pour it into a sandwich pot and mix it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com