Propafenone hydrochloride sustained-release pellet capsule as well as preparation method and application thereof

A technology of propafenone hydrochloride and sustained-release pellets, which can be used in pharmaceutical formulations, medical preparations containing active ingredients, drug delivery, etc. It can solve the problems of wet and soft materials, difficult extrusion and spheronization processes, and material agglomeration , to achieve the effects of slow and stable drug release, increased production efficiency, and improved compliance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

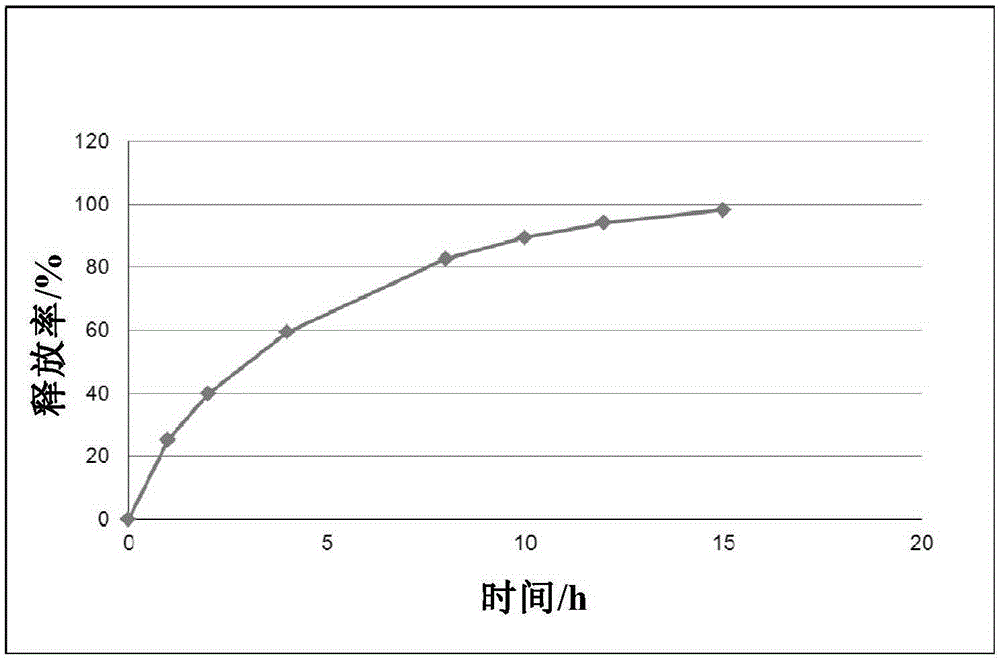

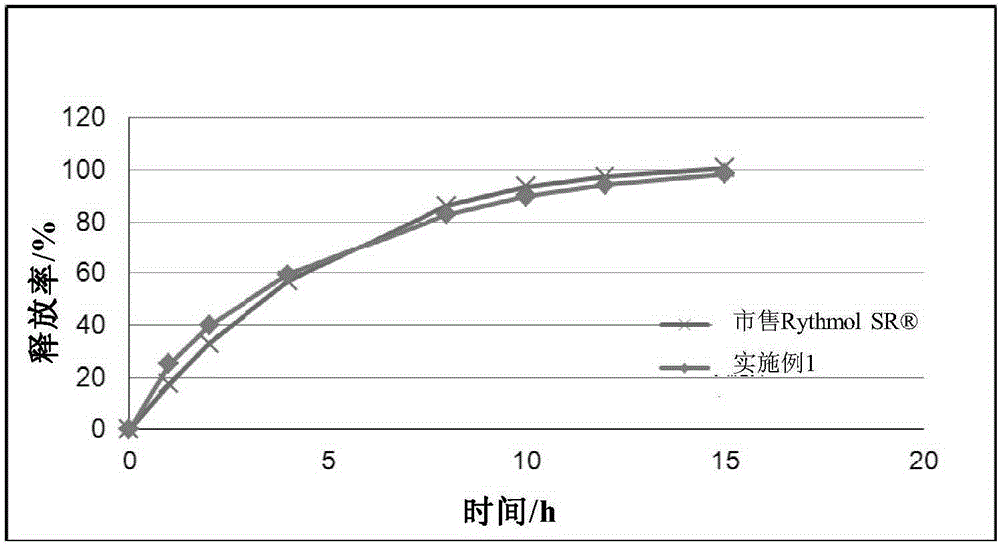

Embodiment 1

[0049] In this embodiment, the propafenone hydrochloride sustained-release pellet capsules comprise the following components in mass percent:

[0050] Propafenone Hydrochloride 69%

[0051] Filler 30%

[0052] Binder 1%

[0053] The filler is a mixture of microcrystalline cellulose (AvicelPH101) and pregelatinized starch (STARCH1500) at a mass ratio of 2:1, and the binder is hypromellose (MethocelK100MCR).

[0054] It is prepared by extrusion spheronization, which specifically includes the following steps:

[0055] (1) Pass propafenone hydrochloride and filler (a mixture of microcrystalline cellulose and pregelatinized starch) through a 30-mesh sieve respectively, mix evenly according to the formula quantity, and add binder (hypromellose) according to the formula quantity element) solution (concentration is 1%) to make soft material;

[0056] (2) The soft material prepared by step (1) is extruded strip material in the extrusion equipment with a sieve plate aperture of 0.8-...

Embodiment 2

[0062] In this embodiment, the propafenone hydrochloride sustained-release pellet capsules comprise the following components in mass percent:

[0063] Propafenone Hydrochloride 72.7%

[0064] Filler 27%

[0065] Binder 0.3%

[0066] The filler is microcrystalline cellulose (AvicelPH102), and the binder is polyoxyethylene (WSR301).

[0067] It is prepared by extrusion spheronization, which specifically includes the following steps:

[0068] (1) After propafenone hydrochloride and filler (microcrystalline cellulose) are passed through a 30-mesh sieve respectively, mix uniformly according to the formula quantity, and add the binder (polyoxyethylene) solution (concentration is 5%) according to the formula quantity made into soft material;

[0069] (2) The soft material prepared in step (1) is extruded into a strip material in a 16-20 mesh extrusion equipment, and the strip material is put into a rounding equipment, and the edge line at 942 m / s Carry out spheronization at high...

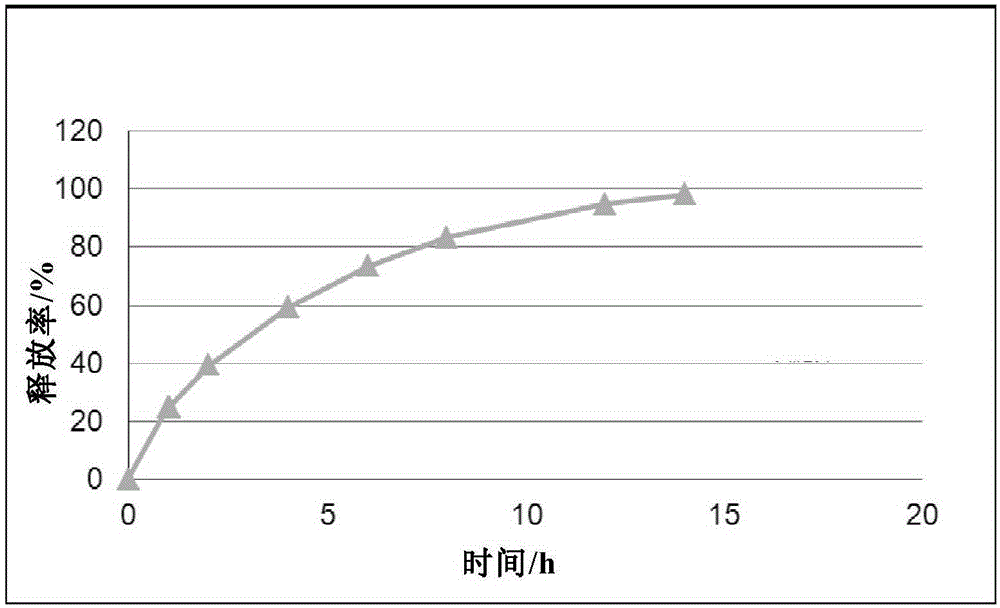

Embodiment 3

[0073] In this embodiment, the propafenone hydrochloride sustained-release pellet capsules comprise the following components in mass percent:

[0074] Propafenone Hydrochloride 72.7%

[0075] Filler 27%

[0076] Binder 0.3%

[0077] The filler is a mixture of microcrystalline cellulose (AvicelPH102) and crospovidone (BASF) at a mass ratio of 1:1, and the binder is hypromellose (MethocelK4MCR).

[0078] It is prepared by extrusion spheronization, which specifically includes the following steps:

[0079] (1) After propafenone hydrochloride and the filler (the mixture of microcrystalline cellulose and crospovidone) are passed through a 30-mesh sieve respectively, they are mixed evenly according to the formula quantity, and the binder (hypromellose) is added according to the formula quantity Cellulose) solution (concentration is 0.01%) is made soft material;

[0080] (2) The soft material prepared in step (1) is extruded strip material in the extrusion equipment with a sieve p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com