Modified quicksand biodiesel catalyst and its preparation method and application

A biodiesel and catalyst technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem that the cost of biodiesel production has not been significantly reduced, and there is no effective The treatment method, high cost of raw materials and other problems, to achieve the effect of enhanced activity, increased catalytic efficiency, and good catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

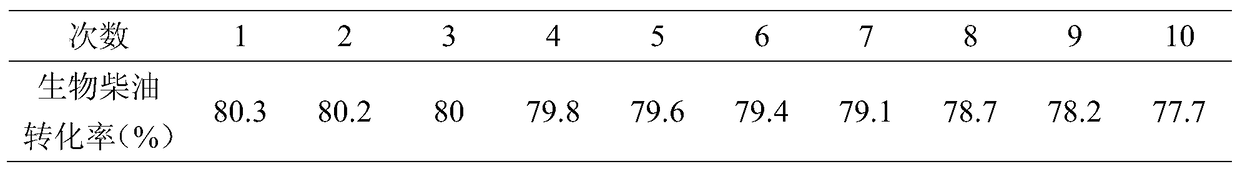

Embodiment 1

[0032] (1) Sampling of quicksand and waste oil:

[0033] The quicksand is taken from the desert, and the waste oil is collected from the food waste in the student canteen. The quicksand is cleaned with deionized water, and the waste oil is centrifuged to remove food residues and particles.

[0034] (2) Preparation of modified quicksand biodiesel catalyst:

[0035] Place the cleaned quicksand in an oven to dry at 100°C, then pass through a 1mm sieve, crush the separated larger particles with a pulverizer, and repeatedly pass through a 1mm sieve; mix the sieved quicksand and sodium hydroxide according to the mass ratio Mixed at 1:1, placed in a muffle furnace, calcined at 700°C for 1 hour, and then pulverized to obtain powder A, soaked in 3mol / L sulfuric acid solution for 1 hour; centrifuged to remove the upper layer, and collected the lower layer of solid Washing with water, calcining the washed solid at 700° C. for 1 hour, cooling and grinding into a powder with a particle s...

Embodiment 2

[0050] (1) The sampling of quicksand and waste oil is the same as in Example 1.

[0051] (2) Preparation of modified quicksand biodiesel catalyst:

[0052] Place the cleaned quicksand in an oven to dry at 100°C, then pass through a 1.25mm sieve, crush the separated larger particles with a pulverizer, and repeatedly pass through a 1.25mm sieve; mix the sieved quicksand with sodium hydroxide according to The mass ratio is 1:1.5 and mixed, placed in a muffle furnace, calcined at 750°C for 2 hours, and then pulverized to obtain powder A. Soak powder A in 3mol / L sulfuric acid solution for 2 hours; centrifuge to remove the supernatant, collect The solid in the lower layer was washed with water, and then the washed solid was calcined at 750° C. for 2 hours, cooled and ground into a powder with a size of 2 mm or less to obtain a modified quicksand biodiesel catalyst for future use. .

[0053] (3) transesterification reaction:

[0054] After heating the reactor to 70°C, keep the con...

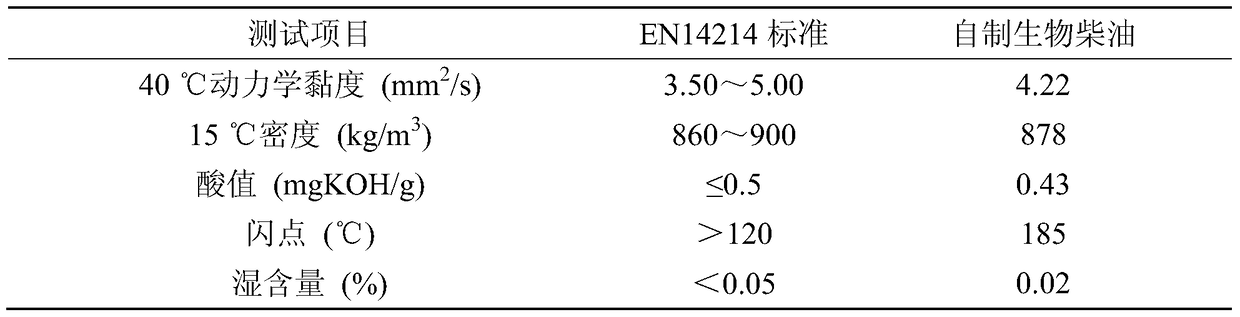

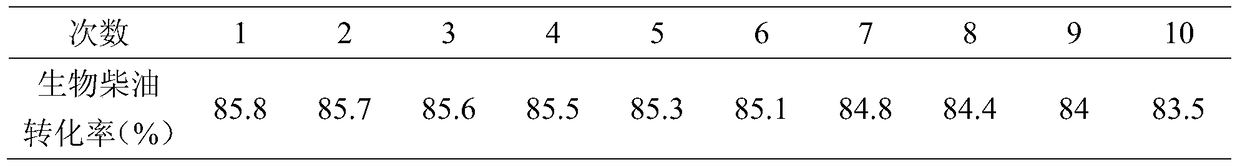

Embodiment 3

[0066] (1) The sampling of quicksand and waste oil is the same as in Example 1.

[0067] (2) Preparation of modified quicksand biodiesel catalyst:

[0068] Same as Example 1, place the cleaned quicksand in an oven to dry at 100°C, then pass through a 1.43mm sieve, break the separated larger particles with a pulverizer, and repeatedly pass through a 1.43mm sieve; the sieved quicksand Mix with sodium hydroxide at a mass ratio of 1:2, place in a muffle furnace, calcined at 800°C for 3 hours, and then pulverize to obtain powder A, soak powder A in 3mol / L sulfuric acid solution for 3h; centrifuge Remove the supernatant, collect the solids in the lower layer and wash them with water, then calcinate the washed solids at 800°C for 3 hours, cool them and grind them into powders below 2mm to obtain the modified quicksand biodiesel catalyst, which is ready for use.

[0069] (3) transesterification reaction:

[0070] After heating the reactor to 80°C, keep the constant temperature, add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com