Mpg-C3N4/BiPO4 compound photocatalyst and preparing method and application thereof

A mpg-c3n4, catalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as composite photocatalysts that have not been reported, achieve excellent photocatalytic performance, and the process is simple and easy The effect of easy control and experimental conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

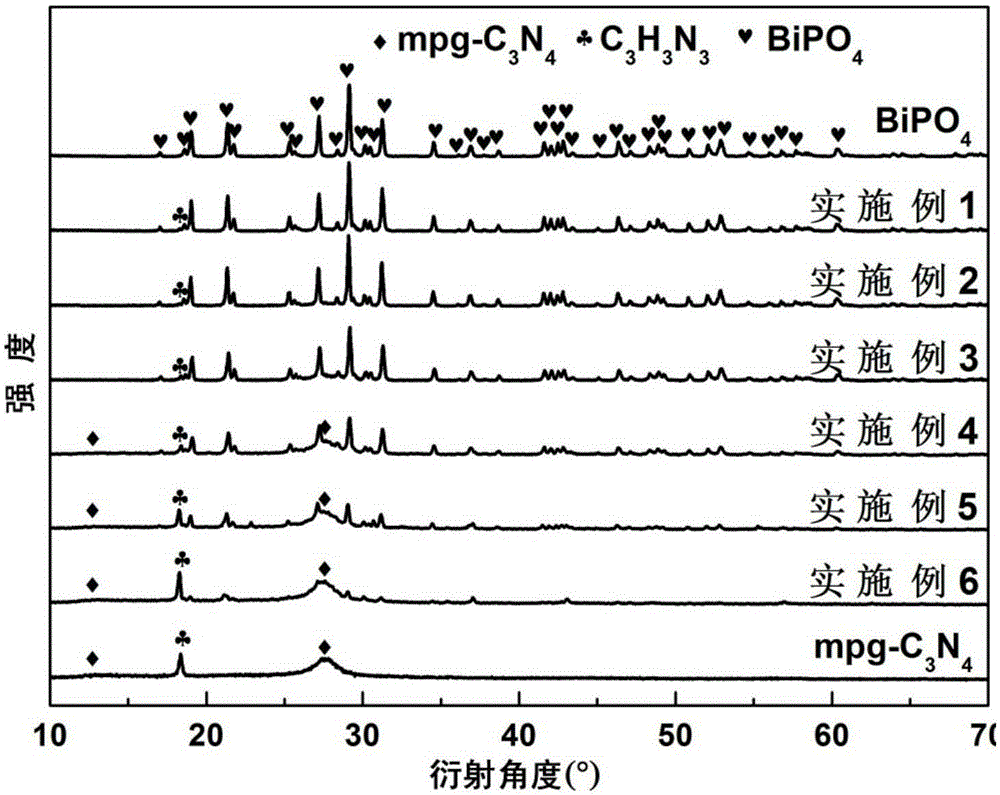

Embodiment 1

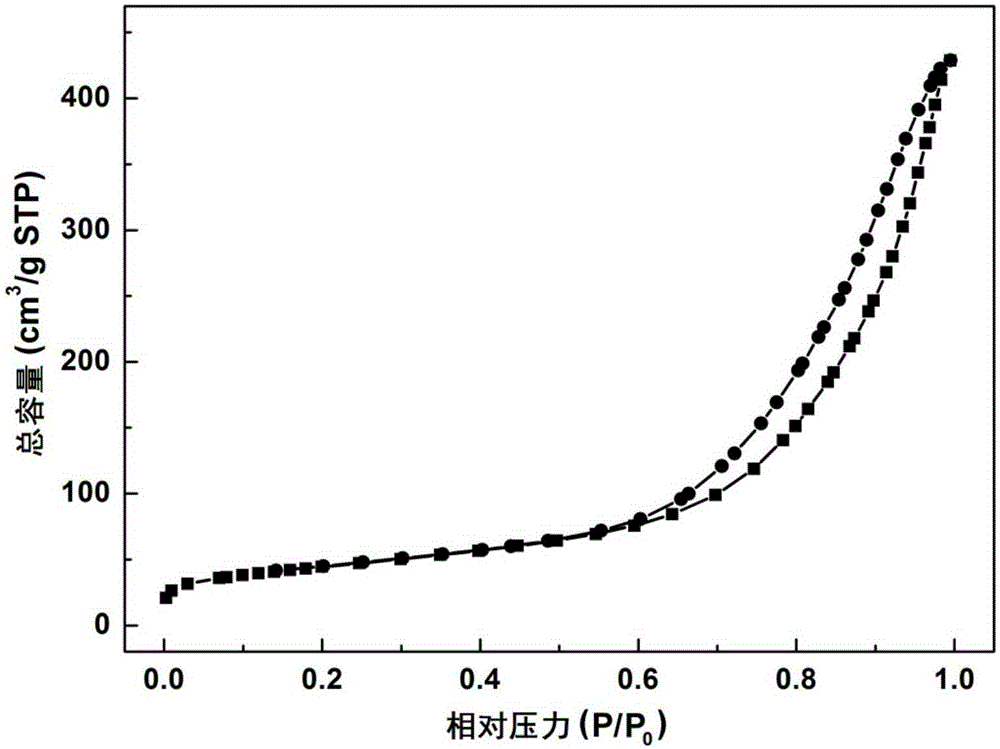

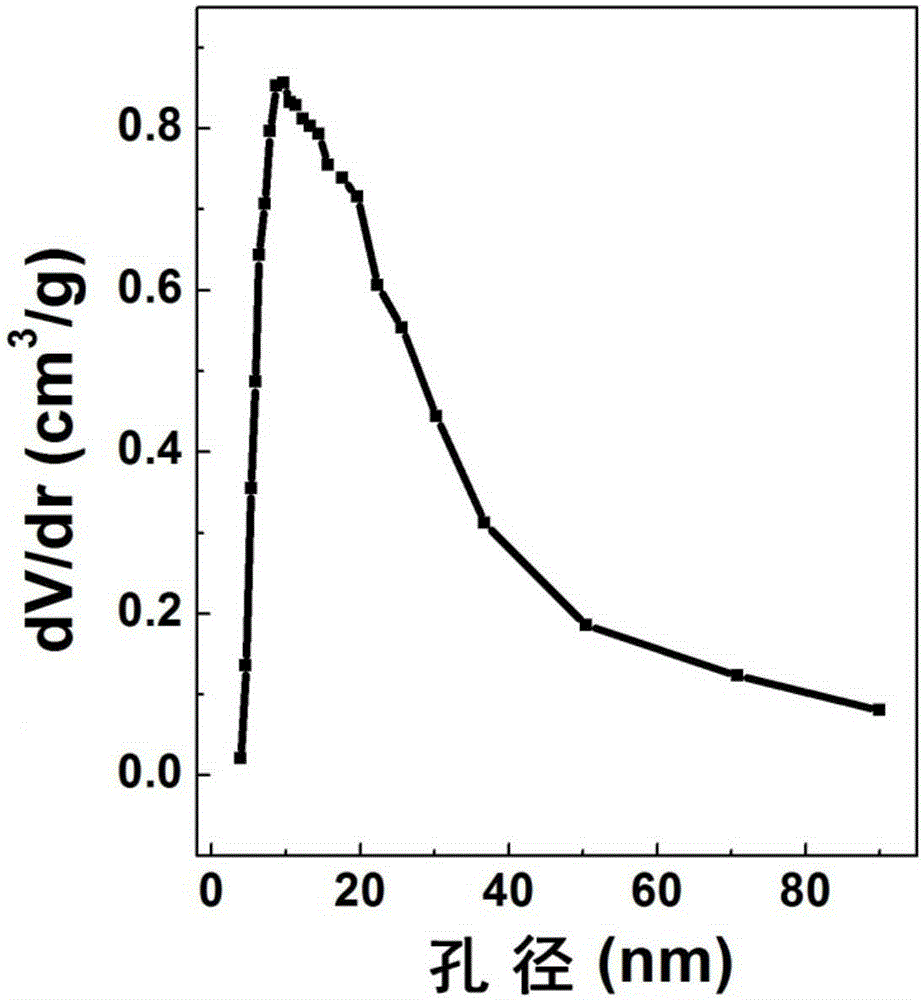

[0030] Step 1: be that melamine is dissolved in silica sol (containing the SiO that massfraction is 40% in silica sol by mass ratio is 10:25 2 , and SiO 2 The average particle size is 12nm), heated and stirred at 100°C until the solvent was evaporated to dryness to obtain a white solid, which was pulverized and put into a muffle furnace, calcined at 550°C for 4 hours, cooled and ground to obtain a yellow powder. The yellow powder is dispersed in 200 mL of NH with a concentration of 4 mol / L 4 HF 2 solution, stirred for 48h to remove SiO 2 The template was washed three times with deionized water and ethanol, and finally dried at 80 °C for 10 h to obtain mesoporous graphite phase carbon nitride (mpg-C 3 N 4 ) powder; prepared mpg-C 3 N 4 The degradation rate of Rhodamine B can reach 92.3% after the powder is irradiated with ultraviolet light for 8 minutes, and the degradation rate of RhB can reach 90.9% after 40 minutes of visible light irradiation.

[0031] Step 2: Na 3 ...

Embodiment 2

[0034] Step 1 and step 2 are the same as step 1 and step 2 of embodiment 1.

[0035] Step 3: Convert mpg-C 3 N 4 Add the powder into ethanol and ultrasonically disperse for 3 hours, then add BiPO to it 4 The powder continued to ultrasonically disperse for 2 hours to obtain a dispersion liquid, and the mpg-C in the dispersion liquid 3 N 4 Powder and BiPO 4 The mass ratio of the powder is 50:50, and the mpg-C in the dispersion 3 N 4 The concentration of the powder is 6g / L, BiPO 4 The concentration of the powder is 6g / L; then the dispersion is continuously stirred at room temperature for 24 hours to obtain a mixed solution, and finally the mixed solution is washed 3 times with deionized water and absolute ethanol, and then dried at a constant temperature at 80°C for 10 hours. get mpg-C 3 N 4 / BiPO 4 composite photocatalyst. mpg-C produced 3 N 4 / BiPO 4 The composite photocatalyst can degrade 92.7% of Rhodamine B after 8 minutes of ultraviolet light irradiation, and ...

Embodiment 3

[0037] Step 1 and step 2 are the same as step 1 and step 2 of embodiment 1.

[0038] Step 3: Convert mpg-C 3 N 4 Add the powder into ethanol and ultrasonically disperse for 3 hours, then add BiPO to it 4 The powder continued to ultrasonically disperse for 2 hours to obtain a dispersion liquid, and the mpg-C in the dispersion liquid 3 N 4 Powder and BiPO 4 The mass ratio of the powder is 70:30, and the mpg-C in the dispersion 3 N 4 The concentration of the powder is 8.4g / L, BiPO 4 The concentration of the powder is 3.6g / L; then the dispersion is continuously stirred at room temperature for 24 hours to obtain a mixed solution, and finally the mixed solution is washed 3 times with deionized water and absolute ethanol, and then dried at a constant temperature at 80°C for 10 hours , get mpg-C 3 N 4 / BiPO 4 composite photocatalyst. mpg-C produced 3 N 4 / BiPO 4 The composite photocatalyst can degrade 92.8% of Rhodamine B after 8 minutes of ultraviolet light irradiation,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com