A kind of tungsten/steel composite material based on high temperature application and its preparation method

A composite material and high-temperature technology, which is applied in chemical instruments and methods, manufacturing tools, welding equipment, etc., can solve problems such as large residual stress of joints, degradation of joint performance, and low performance of joint joints, so as to improve high-temperature mechanical properties and increase room temperature Tensile properties, the effect of improving tensile properties at room temperature and high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The diffusion bonding method of tungsten / steel dissimilar materials based on high-temperature applications in this embodiment is performed as follows:

[0027] 1. Surface cleaning: first use 150#, 400#, 800#, 1200# and 1500# metallographic sandpaper to polish and polish the joint surface of the welding material tungsten and steel to a surface finish of 0.5μm, and then use The ultrasonic cleaner (set the cleaning temperature at 35°C) cleans the materials to be welded in absolute ethanol, acetone, and absolute ethanol for 15 minutes in order to remove the oil and impurities on the surface of the sample to be welded. In order to prevent the material to be welded from being oxidized or contaminated again, place it in absolute ethanol and store it for later use.

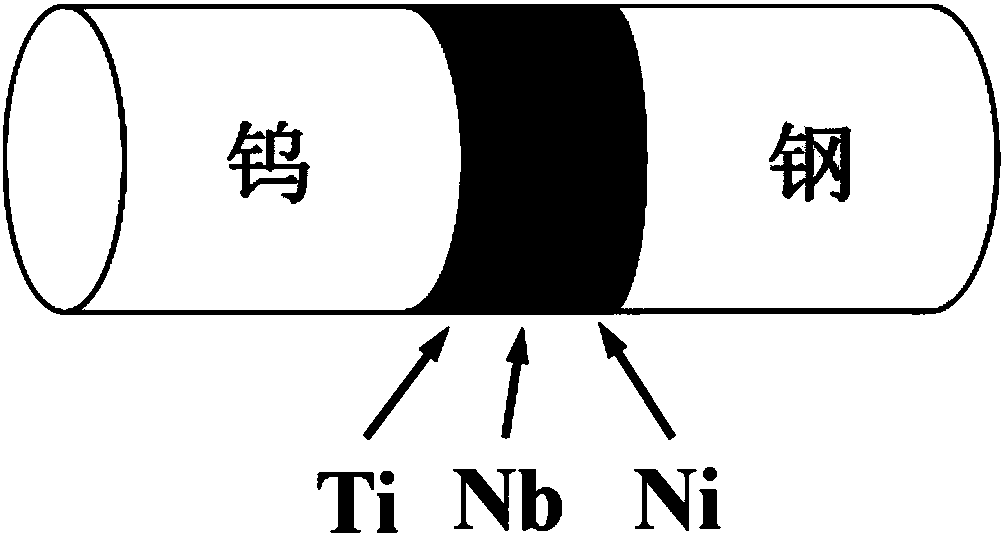

[0028] 2. Pre-set composite structure middle layer: First, the optimized design Ti layer, Nb layer, and Ni layer are processed into thin slices with a thickness of 0.1mm, and then combined into a composite structure mid...

Embodiment 2

[0033] The diffusion bonding method of tungsten / steel dissimilar materials based on high-temperature applications in this embodiment is performed as follows:

[0034] 1. Surface cleaning: first use 150#, 400#, 800#, 1200# and 1500# metallographic sandpaper to polish and polish the connecting surface of the tungsten and steel to be welded to a surface finish of 1μm, and then use ultrasonic The cleaner (set the cleaning temperature to 35°C) cleans the materials to be welded in absolute ethanol, acetone, and absolute ethanol for 10 minutes each to remove oil and impurities on the surface of the sample to be welded. In order to prevent the material to be welded from being oxidized or contaminated again, place it in absolute ethanol and store it for later use.

[0035] 2. Pre-set composite structure middle layer: firstly process the optimized design Ti layer, Nb layer and Ni layer into thin slices with thickness of 0.1, 0.2, 0.5mm respectively, and then combine them into a composite str...

Embodiment 3

[0040] The diffusion bonding method of tungsten / steel dissimilar materials based on high-temperature applications in this embodiment is performed as follows:

[0041] 1. Surface cleaning: first use 150#, 400#, 800#, 1200# and 1500# metallographic sandpaper to polish and polish the joint surface of the welding material tungsten and steel to a surface finish of 3μm, and then use ultrasonic The cleaner (set the cleaning temperature to 35°C) cleans the materials to be welded in absolute ethanol, acetone, and absolute ethanol for 10 minutes each in order to remove oil stains and impurities on the surface of the samples to be welded. In order to prevent the material to be welded from being oxidized or contaminated again, place it in absolute ethanol and store it for later use.

[0042] 2. Pre-set composite structure middle layer: firstly process the optimized design Ti layer, Nb layer and Ni layer into thin slices with thicknesses of 0.05, 0.3, and 0.1mm respectively, and then combine th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com