Application of epoxy cardanol as bio-based hindered phenolic antioxidant

A cardanol and antioxidant technology, which is applied in the field of preparation of bio-based hindered phenol antioxidants, can solve the problems of harsh production conditions, limited promotion and application, expensive catalysts and the like, and achieves easy process control, wide sources and low prices. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

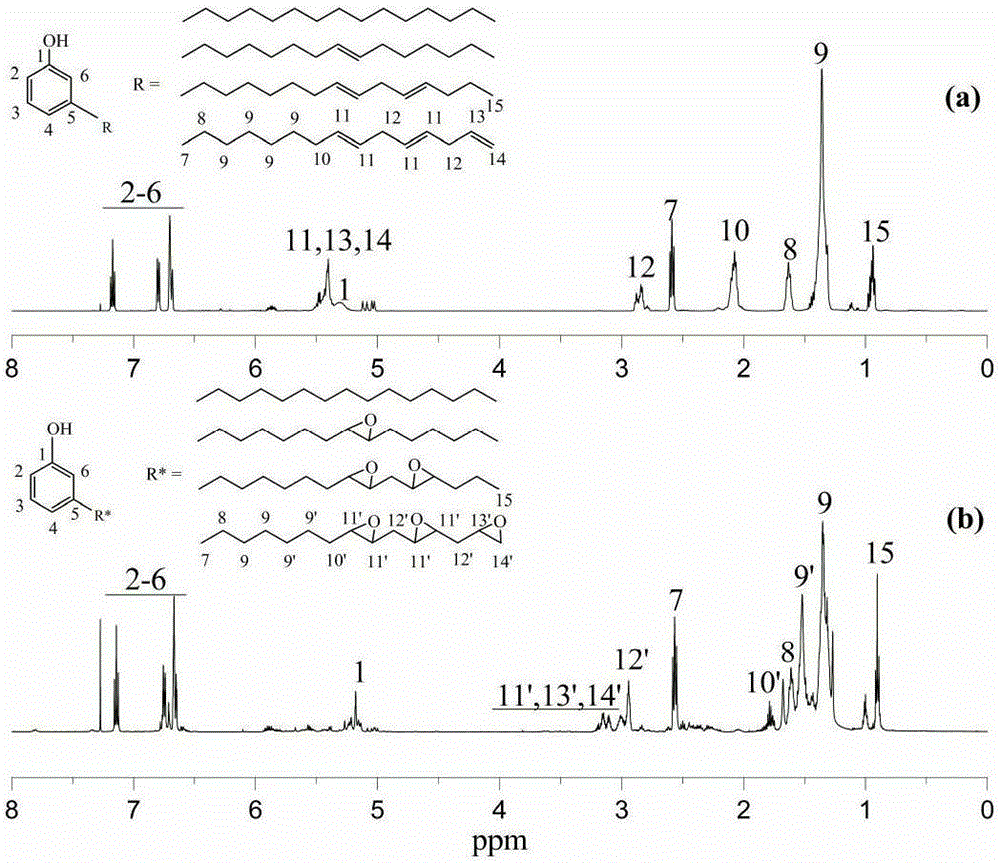

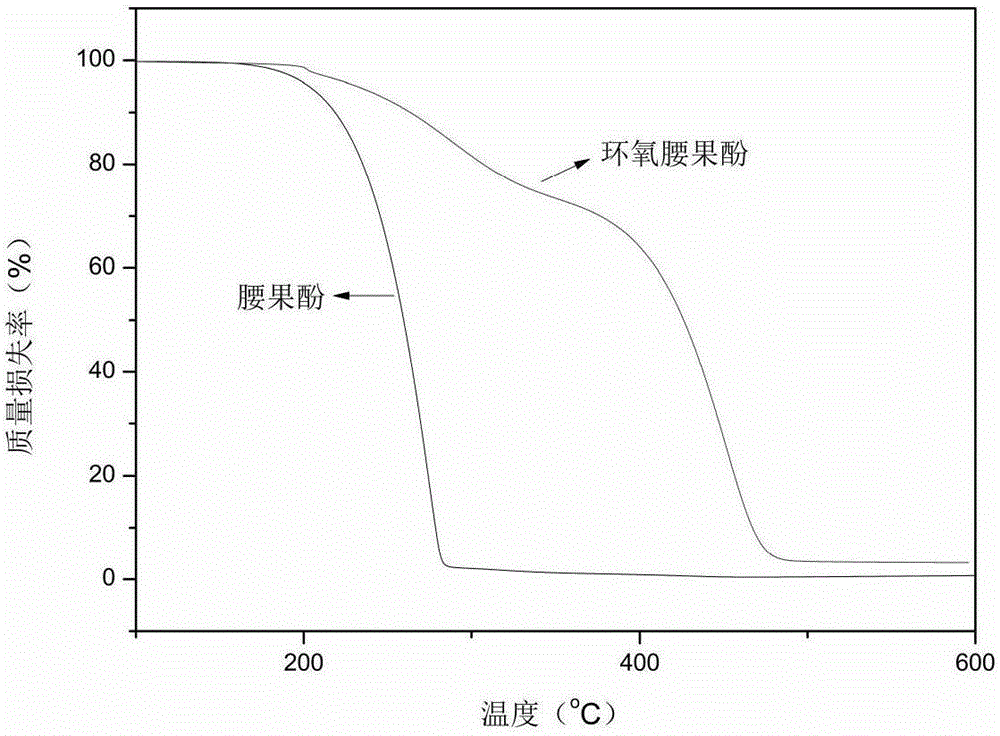

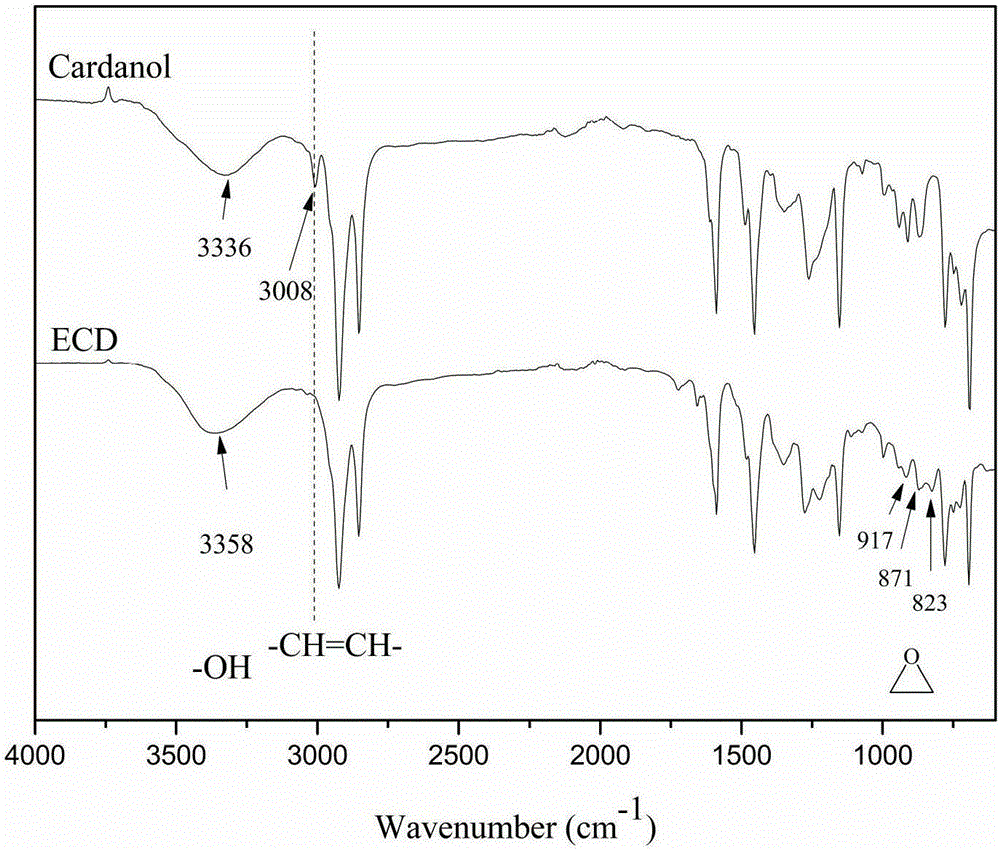

[0035] Weigh 5g of cardanol, 0.8g of formic acid, 0.1g of p-toluenesulfonic acid and 5mL of toluene, add them into a three-necked flask equipped with a condenser, a stirring rod and a thermometer, stir and heat up to 50°C, and dropwise add 5.5g of hydrogen peroxide (50%) , the dropping rate is 10mL / h, after the addition is completed, the reaction system is heated to 65°C for 3 hours; after the reaction, the crude product is obtained by static layering to obtain the organic phase, and the mass fraction of 50°C is 2% sodium bicarbonate solution and 50°C deionized water or distilled water until neutral, flash evaporated to remove water, and recovered the solvent to obtain the finished product of bio-based hindered phenolic antioxidant. The product is a yellow oily liquid with an epoxy value of 3.78%.

Embodiment 2

[0037] Weigh 5g of cardanol, 1.0g of acetic acid, 0.3g of 732 cation exchange resin and 5mL of n-hexane, add them into a three-necked flask equipped with a condenser, a stirring rod and a thermometer, stir and heat up to 55°C, and dropwise add 5.5g of hydrogen peroxide (50%) , the dropping rate is 10mL / h, after the addition is completed, the reaction system is heated to 65°C for 3.5 hours; after the reaction, the crude product is obtained by static layering to obtain the organic phase, and the mass fraction of 50°C is 2% sodium bicarbonate The solution and 50°C deionized water or distilled water were washed until neutral, the water was removed by flash evaporation, and the solvent was recovered to obtain the finished bio-based hindered phenol antioxidant. The product is a yellow oily liquid with an epoxy value of 3.42%.

Embodiment 3

[0039] Weigh 5g of cardanol, 0.9g of formic acid, 0.2g of p-toluenesulfonic acid and 10mL of toluene, add them into a three-neck flask equipped with a condenser, a stirring rod and a thermometer, stir and heat up to 50°C, and dropwise add 6.5g of hydrogen peroxide (30%) , the dropping rate is 50mL / h. After the addition, the temperature of the reaction system is raised to 65°C for 3.5h; after the reaction, the crude product is separated and separated to obtain the organic phase. The solution and 70°C deionized water or distilled water were washed until neutral, the water was removed by flash evaporation, and the solvent was recovered to obtain the finished product of bio-based hindered phenol antioxidant. The product is a yellow oily liquid with an epoxy value of 3.61%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com