A metal oxide iron-copper composite modified quartz sand filter material and its preparation method and application

A composite modification, quartz sand technology, applied in chemical instruments and methods, silicon compounds, separation methods, etc., to achieve the effects of reducing costs, reducing energy consumption, and shortening preparation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

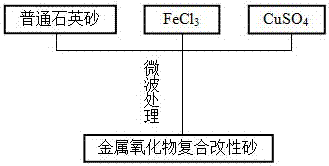

Method used

Image

Examples

Embodiment 1

[0052] Embodiment 1 Preparation of metal oxide iron-copper composite modified quartz sand filter material

[0053] 1. Materials required for the preparation of metal oxide composite modified sand

[0054] (1) The required materials are shown in Table 1.

[0055] Table 1

[0056]

[0057] (2) Handling of test materials

[0058] Ordinary quartz sand (RQS): sieve with a diameter of 0.9-1.43mm, pickle with pH=1 HCl solution for 24 hours, then wash with distilled water until neutral, then dry in an oven at 110°C, cool at room temperature and put it into a polyethylene bottle ready for use.

[0059] Ferric chloride modifier (FeCl 3 ): Accurately weigh 270.5g of ferric chloride hexahydrate (analytical grade) and dissolve in distilled water, transfer to a 500mL volumetric flask, distill the water to 500mL, shake well, the concentration of ferric chloride in this solution is 2.000mol / L . The amount of ferric chloride added per gram of quartz sand is called the ferric chloride ...

Embodiment 2

[0079] Example 2 BET specific surface area and morphology of metal oxide iron-copper composite modified quartz sand filter material

[0080] 1. The size of the specific surface area reflects the size of the particle loading capacity, and the size of the specific surface area is determined by S BET value to measure. Use the BET specific surface area tester F-Sorb2400 to measure the specific surface area of ordinary quartz sand and metal composite oxide modified sand, and calculate the ratio of the specific surface area of the modified sand to the specific surface area of ordinary quartz sand. sexual effect. It can be obtained from Table 6 that the specific surface area of metal oxide composite modified sand is 8.96 times that of ordinary quartz sand.

[0081] The BET specific surface area measurement result of table 6 filter sand

[0082]

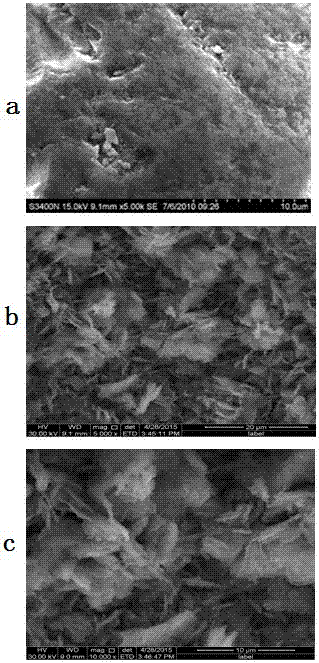

[0083] 2. The physical picture of metal oxide composite modified sand figure 2 , The particle size range of the metal oxide...

Embodiment 3

[0084] SEM scanning electron microscope picture of metal oxide composite modified sand image 3 , combining Table 6 and image 3 (a), the surface of ordinary quartz sand is smooth, the specific surface area is small, and the adsorption capacity is small. image 3 (b) and (c) are scanning electron microscope images of the surface of composite modified quartz sand enlarged by 5000 and 10000 times. It can be seen that the surface of metal oxide composite modified sand has very clear and dense pores, and the specific surface area is 0.959, which is ordinary quartz. 8.96 times that of sand, and has a larger adsorption capacity than ordinary quartz sand. The substance attached to the surface of the modified quartz sand is Fe 2 o 3 and CuO, making metal oxides successfully modified on the surface of ordinary quartz sand, Fe 3+ and Cu 2 + The positive charge on the surface of ordinary quartz sand is increased, which has a very good adsorption effect on negative charge organic po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com