Preparation method of high activity oxidized nanocrystalline cellulose based titanium dioxide

A nanocrystalline cellulose and titanium dioxide-based technology, which is applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problem of improving the catalytic activity of nano-titanium dioxide products, cellulose whose size is nano-scale, and unresolved problems. Involves issues such as the preparation of nano-titanium dioxide particles, achieving high safety and biodegradability, reducing adverse effects, and reducing application costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

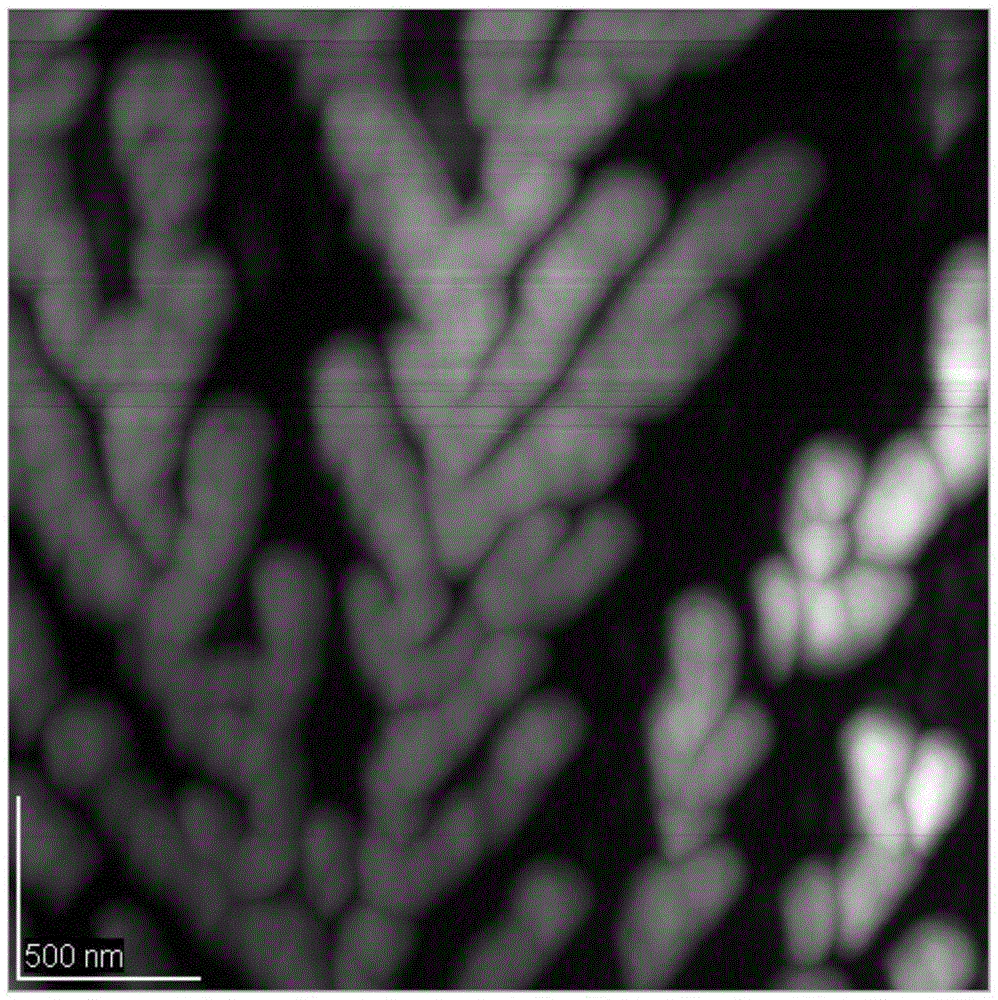

[0049] A preparation method of highly active oxidized nanocrystalline cellulose-based titanium dioxide, which adopts the preparation method of homogeneous sol and high-temperature calcination method. active agent, or no surfactant is added to the mixed solution, the precursor of which is n-butyl titanate, the substrate is oxidized nanocrystalline cellulose rich in dialdehyde groups, and the auxiliary materials include inorganic salts Thickener, and anionic surfactant and supplemented with an appropriate amount of amphoteric surfactant or nonionic surfactant, the morphology of the prepared titanium dioxide crystal particles is wheat ear-shaped, highly active nano-sized solid particles, in water It has good dispersion and can effectively improve its treatment efficiency for pigments in wastewater. The operation process of its preparation steps is:

[0050] 1) Prepare the organic solvent solution A of the precursor n-butyl titanate, selectively add thickeners and surfactants to t...

Embodiment 2

[0070] A preparation method of highly active oxidized nanocrystalline cellulose-based titanium dioxide, the preparation process steps of which are the same as in Example 1, except that the selected organic solvent is isopropanol and the selected thickener is potassium chloride, and Do not add amphoteric surfactant in the mixed solution, and its preparation step operation process is:

[0071] One), prepare the organic solvent solution A of the precursor n-butyl titanate, selectively add thickener and surfactant in the solution

[0072] Take 5g of n-butyl titanate precursor and add it to isopropanol, the mass ratio of n-butyl titanate to isopropanol is 1:6.5, add 0.2g potassium chloride thickener, 0.35g fatty alcohol polyoxyethylene Sodium ether sulfate anionic surfactant and 0.15g coconut oil monoethanolamide nonionic surfactant were added to the mixed solution respectively, hydrochloric acid was added to adjust the pH to 3, and the organic solvent solution A of the precursor w...

Embodiment 3

[0083] A method for preparing highly active oxidized nanocrystalline cellulose-based titanium dioxide, the preparation process steps of which are the same as in Example 1, except that: the selected organic solvent is isopropanol and the selected thickener is ammonium chloride. Its preparation step operation process is:

[0084] One), prepare the organic solvent solution A of the precursor n-butyl titanate, selectively add thickener and surfactant in the solution

[0085] Take 6g of n-butyl titanate precursor and add it to isopropanol, the mass ratio of n-butyl titanate to isopropanol is 1:5.5, add 0.5g ammonium chloride thickener, 0.3g lauryl sulfate Sodium anionic surfactant and 0.15g ethylene glycol distearate nonionic surfactant were added to the mixed solution respectively, hydrochloric acid was added to adjust the pH to 3.5, and the organic solvent solution of the precursor was prepared by processing with a low-speed shearing machine for 28 minutes A, the speed control o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com