Method for producing cyclohexanone oxime

A technology of cyclohexanone oxime and cyclohexylamine, applied in oxime preparation, organic chemistry, etc., can solve the problems of cyclohexylamine quality reduction, cyclohexylamine quality increase, economic limitations, etc., to achieve economical benefits, The effect of simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

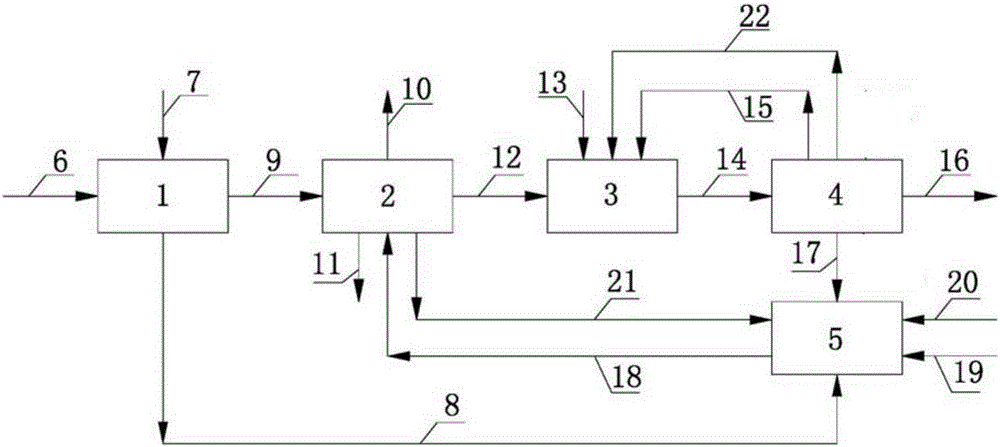

Image

Examples

Embodiment 1

[0102] Hydrogen (7) and aniline (6) are mixed at a molar ratio of 20:1, and enter the aniline evaporator to vaporize the aniline. The flow rate of aniline is 605kg / h, and the flow rate of supplemented fresh hydrogen is 39.5kg / h (443.28Nm3 / h). After the vaporized mixed gas from the evaporator is overheated, it enters the vertical multi-tube fixed-bed hydrogenation reactor pre-installed with catalyst for hydrogenation reaction. The catalyst in the hydrogenation reactor is a cobalt-based catalyst, chemical composition: Co 2 o 3 +CaCO 3 : ≥88%; of which Co2O3≥45%, loss on ignition: ≤12%.

[0103] The pressure of the hydrogenation reaction is normal pressure, and the bed temperature of the hydrogenation reactor is 165° C., and gradually increases to 190° C. with the reaction. Aniline space velocity is controlled at 0.1h -1 . The contents of the crude products produced by the hydrogenation reaction are: 1% cyclohexane, 96% cyclohexylamine, 0.4% aniline, 2.5% dicyclohexylamine,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com