Method for controlling combustion process of circulating fluidized bed boiler on basis of multivariable generalized predictive control optimization

A generalized predictive control and circulating fluidized bed technology, which is applied in the direction of fluidized bed combustion equipment, combustion methods, fuels burned in a molten state, etc., can solve the problems of high environmental and training maintenance costs, difficulty in establishing mathematical models, and difficulty in implementation, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be described in further detail below in conjunction with the accompanying drawings.

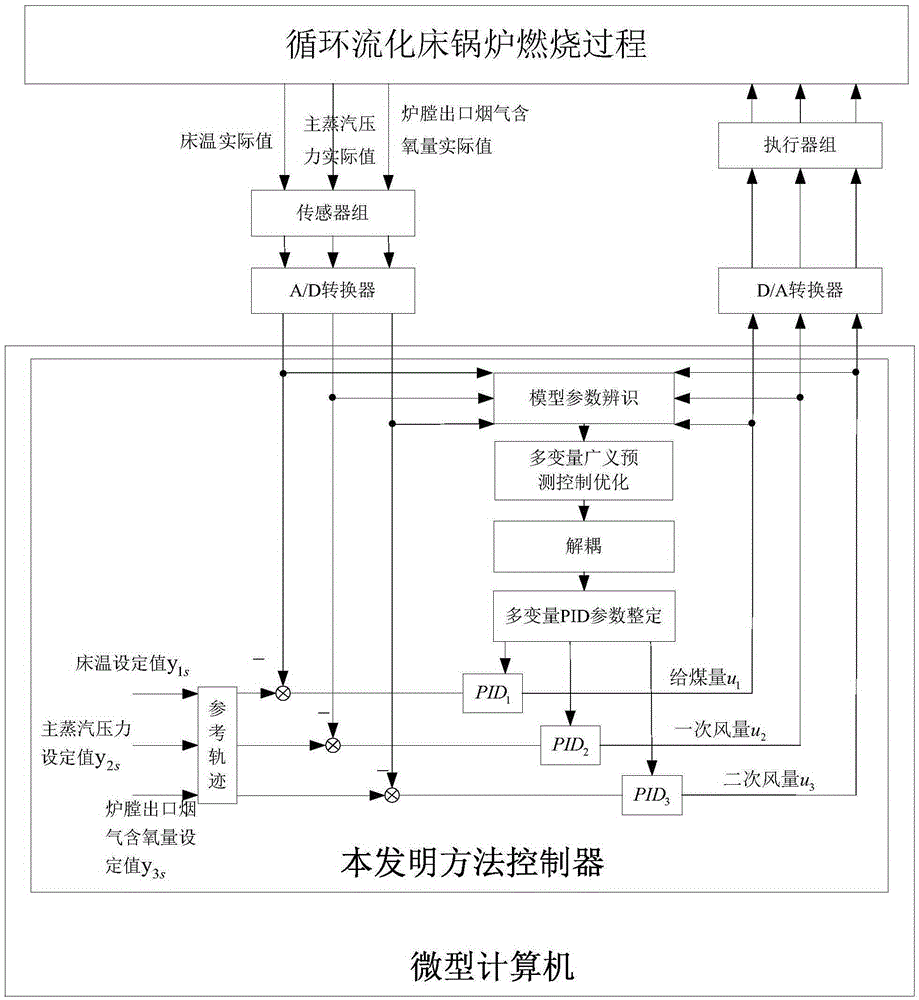

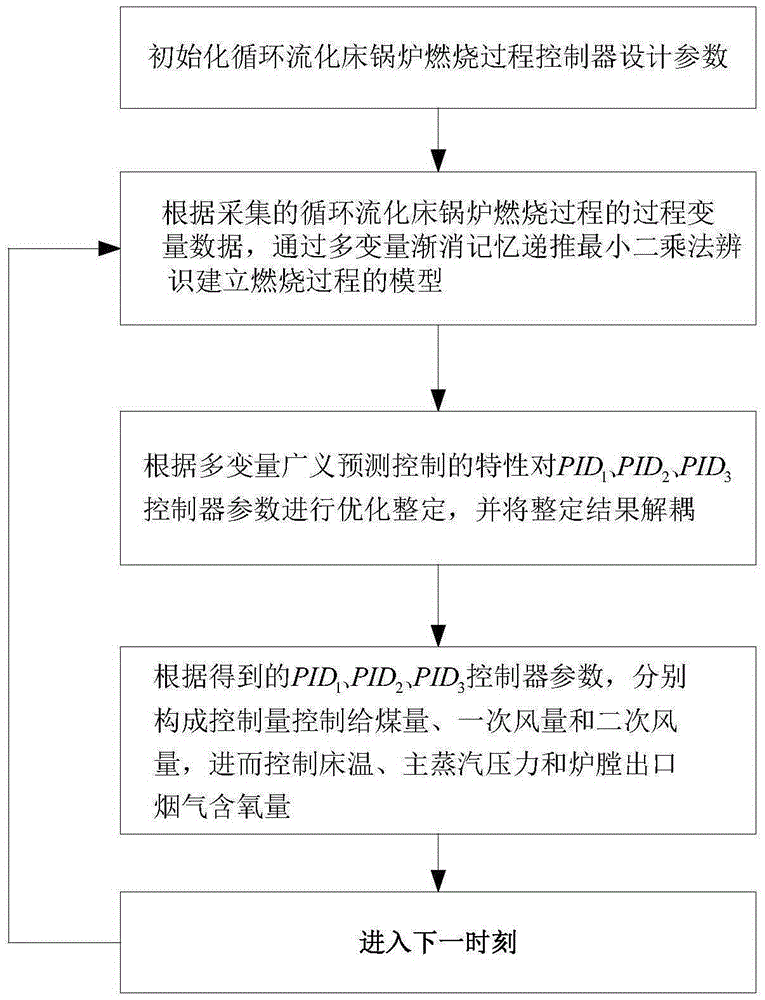

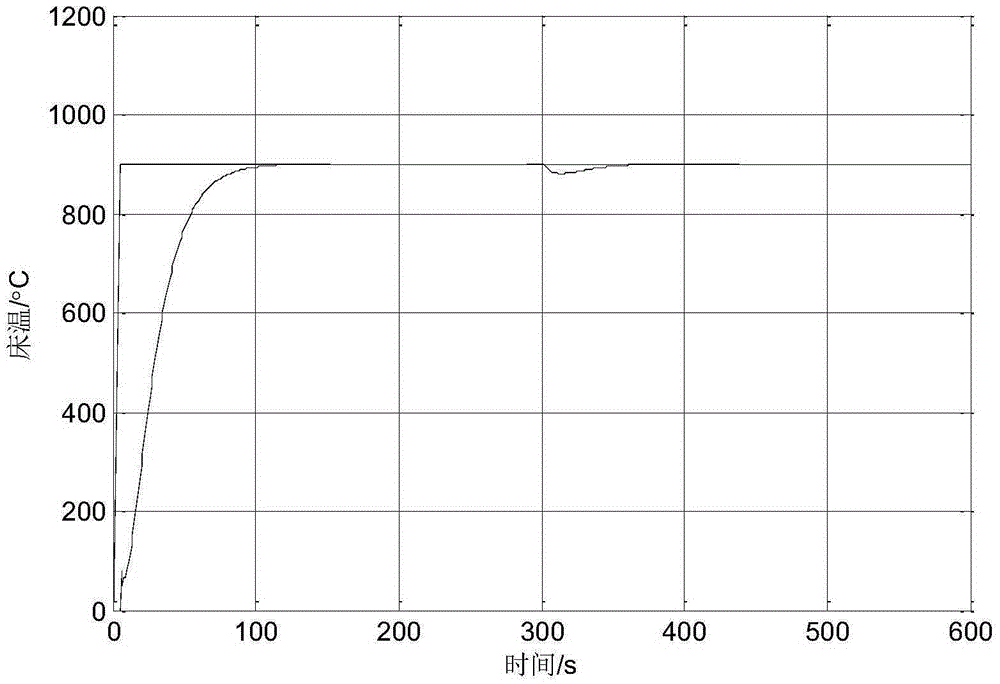

[0061] The combustion process of circulating fluidized bed boilers has complex characteristics such as strong coupling, multi-variable, slow time-varying, and large lag. The controlled variables are: bed temperature, main steam pressure, and oxygen content of flue gas at the furnace outlet. volume, primary air volume, and secondary air volume.

[0062] figure 1 Schematic diagram of the structure of the combustion process control system of the circulating fluidized bed boiler for realizing the method of the present invention. It is composed of microcomputer, A / D converter, D / A converter, sensor, actuator, etc., and the control software written according to the method of the present invention is solidified in the microcomputer. The control system regularly samples the analog parameters of the bed temperature, main steam pressure and oxygen content of the flue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com