Preparation method for slow-release type ferrate solid oxidizing agent and application of preparation method

A ferrate, slow-release technology, applied in chemical instruments and methods, iron compounds, oxidized water/sewage treatment, etc., can solve the problems of inconvenient storage and transportation, easy decomposition, waste, etc., and achieve good slow-release effect, The preparation process is simple and the promotion effect is promoted

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

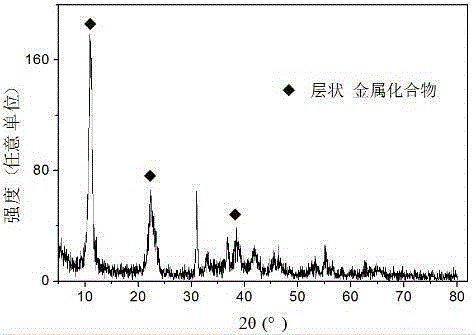

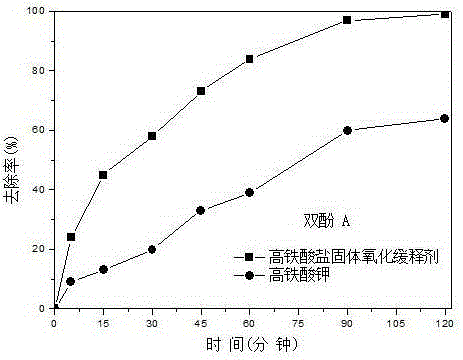

[0025] In the embodiment of the present invention, a preparation method of slow-release ferrate solid oxidant, the specific steps are as follows:

[0026] (1) Weigh calcium chloride dihydrate, aluminum chloride hexahydrate, potassium ferrate solid and appropriate amount of sodium hydroxide according to the molar ratio of Ca:Al:Fe 1:1:1.

[0027] (2) Dissolve calcium chloride dihydrate and aluminum chloride hexahydrate in carbon dioxide-free deionized water to obtain solution A; dissolve potassium ferrate solid and appropriate amount of sodium hydroxide in another carbon dioxide-free deionized water to maintain Solution B was obtained at a pH of 12.

[0028] (3) Add the above two solutions into two continuous sampling pumps respectively, and inject them into the reaction vessel through the nozzle at the same time. During the above process, the flow rates of the two were controlled so that the pH value of the mixed solution in the reaction vessel was maintained at 13, and the s...

Embodiment 2

[0037] In the embodiment of the present invention, a preparation method of slow-release ferrate solid oxidant, the specific steps are as follows:

[0038] (1) Weigh calcium chloride dihydrate, aluminum chloride hexahydrate, potassium ferrate solid and appropriate amount of sodium hydroxide according to the molar ratio of Ca:Al:Fe 3:1:2.

[0039] (2) Dissolve calcium chloride dihydrate and aluminum chloride hexahydrate in carbon dioxide-free deionized water to obtain solution A; dissolve potassium ferrate solid and appropriate amount of sodium hydroxide in another carbon dioxide-free deionized water to maintain Solution B was obtained at a pH of 12.

[0040] (3) Add the above two solutions into two continuous sampling pumps respectively, and inject them into the reaction vessel through the nozzle at the same time. During the above process, the flow rates of the two were controlled so that the pH value of the mixed solution in the reaction vessel was maintained at 13, and the s...

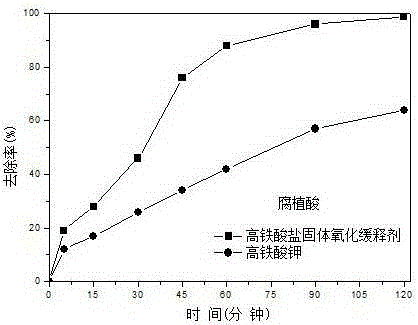

Embodiment 3

[0047] In the embodiment of the present invention, a preparation method of slow-release ferrate solid oxidant, the specific steps are as follows:

[0048] (1) Weigh magnesium chloride hexahydrate, aluminum chloride hexahydrate, potassium ferrate solid and appropriate amount of sodium hydroxide according to the molar ratio of Mg:Al:Fe 3:2:2.

[0049] (2) Mix and dissolve magnesium chloride hexahydrate and aluminum chloride hexahydrate in deionized water without carbon dioxide to obtain solution A; dissolve potassium ferrate solid and appropriate amount of sodium hydroxide in another part of deionized water without carbon dioxide to maintain the pH value Solution B was obtained at 12.

[0050] (3) Add the above two solutions into two continuous sampling pumps respectively, and slowly inject them into the reaction vessel through the pipeline at the same time. During the above process, the flow rates of the two were controlled so that the pH value of the mixed solution in the rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com