Mineral composite premixing fertilizer and preparation method thereof

A compound premixing and mineral technology, applied in the direction of fertilizer mixture, fertilization equipment, application, etc., can solve the problems of easy conversion and deterioration of amino acids, absorption and utilization discount, etc., to improve the aggregate structure and physical and chemical properties, improve natural fertility and water retention function Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

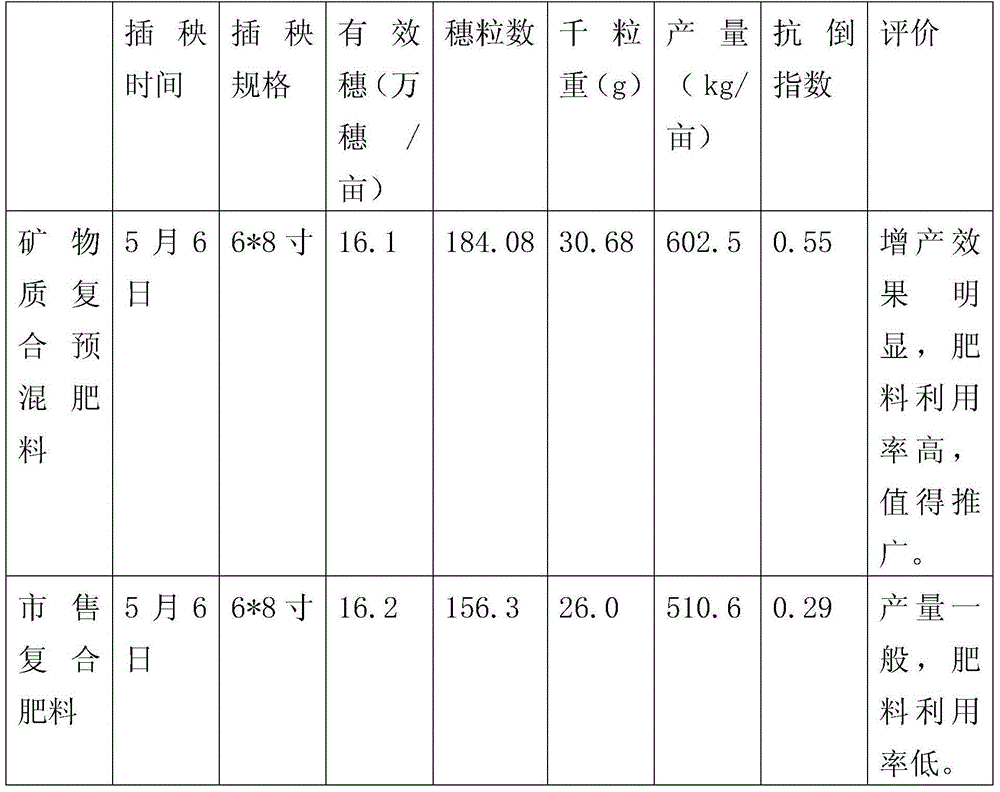

Image

Examples

Embodiment 1

[0021] 1. Add water to the collected 87kg of fresh manure to make the water content 50%, add 6kg of bacterial fertilizer after 1 month of composting, and make it again after 1 month of composting. The bacterial fertilizer: the following weight ratio Made of raw materials: 10% of Bacillus subtilis, 10% of Bacillus thermophile, 25% of Bacillus natto, 15% of Bacillus megaterium, 15% of Bacillus jelly-like, 25% of Azotobacter torus;

[0022] Two, the ammonium sulfate 1.5kg, ammonium dihydrogen phosphate 1.5kg, unslaked lime 3kg, potassium sulfate 3kg, plant ash 2kg are obtained after ultrafine grinding, and its particle size range is stand-by after 0.0002mm;

[0023] 3. Granulation: Mix and granulate fermented manure, ammonium sulfate, ammonium dihydrogen phosphate, quicklime, potassium sulfate, and plant ash. The particle size is 2mm. In the attapulgite powder of the mesh sieve; make the powder completely cover the surface of the granular material, and obtain the fertilizer.

Embodiment 2

[0025] 1. Take 90kg of fresh manure, 0.8kg of ammonium sulfate, 0.8kg of ammonium dihydrogen phosphate, 1.8kg of quicklime, 1.3kg of potassium sulfate, 1kg of plant ash, 1kg of attapulgite powder, and 3.3kg of bacterial fertilizer.

[0026] Two, the implementation steps are the same as in Example 1.

Embodiment 3

[0028] 1. Take 85kg of fresh manure, 1.5kg of ammonium sulfate, 1.5kg of ammonium dihydrogen phosphate, 1.8kg of quicklime, 3kg of potassium sulfate, 1.2kg of plant ash, 1kg of attapulgite powder, and 5kg of bacterial fertilizer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com